Self-tapping screws have various names. They’re often called metal screws, sheet metal screws, tapping screws, or tapper screws. Their tips come in different shapes: pointed (like a pencil), blunt, or flat, and they are described as thread-forming, thread-cutting, or thread rolling. If the screw is pointed, it will be thread-cutting – tapping and creating threads in a pre-drilled hole. If the tip is flat, it is thread-rolling – rolling or extruding threads and creating zero clearance between screw and material.

When it comes to selecting the right self-tapping screw, it’s important to consider the material the screw will be used on. Different types of self-tapping screws are designed for specific materials, such as wood, metal, or plastic. The size and length of the screw should also be considered, as well as the desired level of torque, or tightening force, required for the application. Self-tapping screws are generally easy to install and can be used with a variety of tools, including power drills and screwdrivers. However, it’s important to note that over-tightening can cause the screw to strip the threads, reducing its holding power. It’s also important to ensure that the pilot hole, or hole that the screw is inserted into, is the correct size and shape to ensure proper thread formation and holding power.

The most important difference between self-tapping and self-drilling screws is that self-tapping screws cannot go through metal without a pilot hole, which must be pre-drilled or pre-punched. One of the main advantages of self-tapping screws is that they do not require pre-tapping, which is the process of creating threads in the material before inserting the screw. This eliminates the need for additional tools and can save time and labor costs. Additionally, self-tapping screws can be used in materials that are too thin or brittle to be pre-tapped, making them a versatile choice for a wide range of applications.

Exact drill or punch hole size is also important. The screw will become loose and not thread properly and securely if the hole’s too big. If the hole’s too small, the screw can break or cause the material to split or crack. Self-tapping screws are good for use with metals, various types of plastics (plywood, fiberglass, polycarbonates), and cast or forged material, like iron, aluminum, brass or bronze. Self-tapping screws also work for surfaces where you can’t secure the rear end with a nut. Common applications include fastening aluminum sections, attaching metal brackets onto wood, or inserting screws into plastic housings. In conclusion, self-tapping screws are a versatile and convenient option for creating threads in a variety of materials. They are easy to install and can save time and labor costs, making them a popular choice for many applications. By considering the material, size, length, and thread pattern of the screw, and by following proper installation techniques, you can ensure that your self-tapping screws will provide a secure and reliable hold.

- 선적일에 고객이 우리 공장을 방문하여 자체 드릴링 나사 선적을 검사했습니다.

- 우리 고객들은 우리의 모든 제품이 빛나는 표면 처리로 최고 품질이라는 것을 알게 되어 기뻐했습니다.

- 아연 도금 셀프 드릴링 나사는 부식과 녹에 저항하도록 특별히 설계되어 어떤 환경에서도 안전하고 안정적으로 유지됩니다.

- 회사로서 우리는 제품 품질에 최선을 다하고 있으며 이것이 바로 최고의 재료와 최신 기술을 사용하여 자체 드릴링 나사를 생산하는 이유입니다.

- 결론적으로 우리 방문객들은 선적 검사에 깊은 인상을 받았고 우리 제품의 품질과 포장에 매우 만족했습니다.

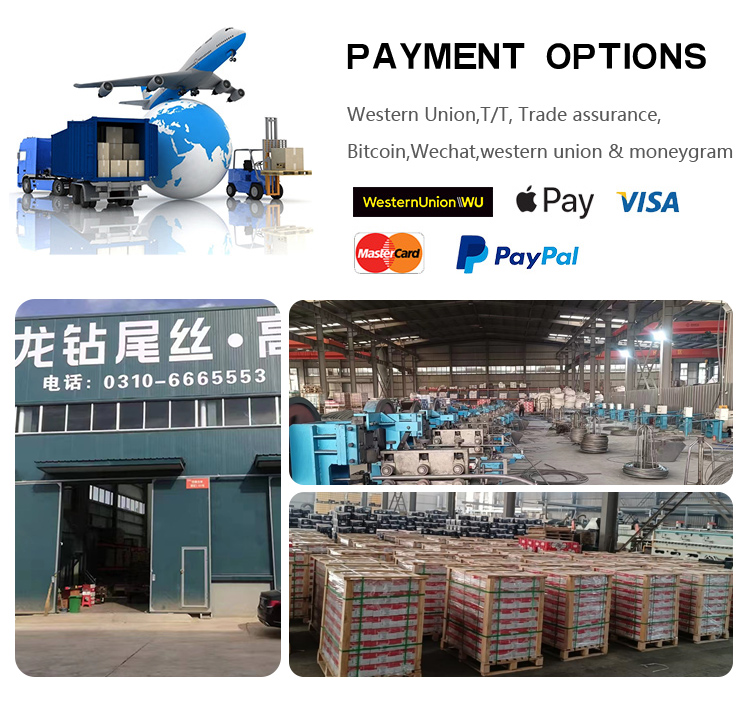

Hebei Delong Fastener Manufacturing Co., Ltd.는 패스너 유통 센터인 하북성 한단시 Yongnian 지구에 위치하고 있습니다. 베이징 주하이 고속도로, 베이징 광저우 철도 및 107번 국도와 가깝습니다. 교통이 편리하고 지리적 위치가 우월합니다.

Hebei Delong Fastener Manufacturing Co., Ltd.는 패스너 유통 센터인 하북성 한단시 Yongnian 지구에 위치하고 있습니다. 베이징 주하이 고속도로, 베이징 광저우 철도 및 107번 국도와 가깝습니다. 교통이 편리하고 지리적 위치가 우월합니다.

이 회사는 2006년에 설립되었습니다. 이 회사는 연간 생산 능력이 8000톤 이상인 고급 패스너의 R&D에 중점을 둡니다. 그것은 대만에서 일류 생산 장비, 기술 및 열처리 장비를 보유하고 있습니다.

총지배인: 미스터 진

전화: 86-310-6665553

이동하는: +86 13703109255

왓츠앱: +8615932307696

웹스티: www.delongfastener.com

이메일: sales@delongfastener.com