Self-tapping screws have various names. They’re often called metal screws, sheet metal screws, tapping screws, or tapper screws. Their tips come in different shapes: pointed (like a pencil), blunt, or flat, and they are described as thread-forming, thread-cutting, or thread rolling. If the screw is pointed, it will be thread-cutting – tapping and creating threads in a pre-drilled hole. If the tip is flat, it is thread-rolling – rolling or extruding threads and creating zero clearance between screw and material.

When it comes to selecting the right self-tapping screw, it’s important to consider the material the screw will be used on. Different types of self-tapping screws are designed for specific materials, such as wood, metal, or plastic. The size and length of the screw should also be considered, as well as the desired level of torque, or tightening force, required for the application. Self-tapping screws are generally easy to install and can be used with a variety of tools, including power drills and screwdrivers. However, it’s important to note that over-tightening can cause the screw to strip the threads, reducing its holding power. It’s also important to ensure that the pilot hole, or hole that the screw is inserted into, is the correct size and shape to ensure proper thread formation and holding power.

The most important difference between self-tapping and self-drilling screws is that self-tapping screws cannot go through metal without a pilot hole, which must be pre-drilled or pre-punched. One of the main advantages of self-tapping screws is that they do not require pre-tapping, which is the process of creating threads in the material before inserting the screw. This eliminates the need for additional tools and can save time and labor costs. Additionally, self-tapping screws can be used in materials that are too thin or brittle to be pre-tapped, making them a versatile choice for a wide range of applications.

Exact drill or punch hole size is also important. The screw will become loose and not thread properly and securely if the hole’s too big. If the hole’s too small, the screw can break or cause the material to split or crack. Self-tapping screws are good for use with metals, various types of plastics (plywood, fiberglass, polycarbonates), and cast or forged material, like iron, aluminum, brass or bronze. Self-tapping screws also work for surfaces where you can’t secure the rear end with a nut. Common applications include fastening aluminum sections, attaching metal brackets onto wood, or inserting screws into plastic housings. In conclusion, self-tapping screws are a versatile and convenient option for creating threads in a variety of materials. They are easy to install and can save time and labor costs, making them a popular choice for many applications. By considering the material, size, length, and thread pattern of the screw, and by following proper installation techniques, you can ensure that your self-tapping screws will provide a secure and reliable hold.

- Le jour du chargement, le client a visité notre usine pour inspecter son envoi de vis autoperceuses.

- Nos clients ont été ravis de voir que tous nos produits étaient de la plus haute qualité avec un traitement de surface brillant.

- Les vis autoperceuses zinguées sont spécialement conçues pour résister à la corrosion et à la rouille, garantissant qu'elles restent sûres et stables dans n'importe quel environnement.

- En tant qu'entreprise, nous nous engageons sur la qualité des produits, et c'est pourquoi nous utilisons les meilleurs matériaux et les dernières technologies pour produire nos vis autoperceuses.

- En conclusion, nos visiteurs ont été impressionnés par l'inspection de leur expédition et ont été très satisfaits de la qualité et de l'emballage de nos produits.

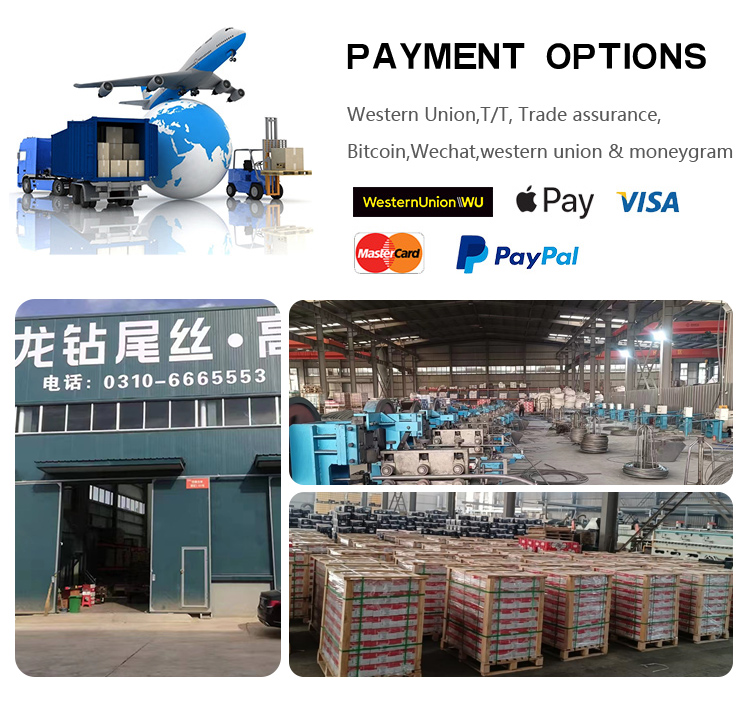

Hebei Delong Fastener Manufacturing Co., Ltd. est situé dans le district de Yongnian, ville de Handan, province du Hebei, le centre de distribution des fixations. Il est proche de l'autoroute Beijing Zhuhai, du chemin de fer Beijing Guangzhou et de l'autoroute nationale 107. Il dispose d'un transport pratique et d'une situation géographique supérieure.

Hebei Delong Fastener Manufacturing Co., Ltd. est situé dans le district de Yongnian, ville de Handan, province du Hebei, le centre de distribution des fixations. Il est proche de l'autoroute Beijing Zhuhai, du chemin de fer Beijing Guangzhou et de l'autoroute nationale 107. Il dispose d'un transport pratique et d'une situation géographique supérieure.

L'entreprise a été fondée en 2006. L'entreprise se concentre sur la R&D de fixations haut de gamme, avec une capacité de production annuelle de plus de 8000 tonnes. Il dispose d'un équipement de production, d'une technologie et d'un équipement de traitement thermique de première classe à Taiwan

Directeur général: Monsieur Jin

TÉL : 86-310-6665553

Mobile: +86 13703109255

Quelle est l'application : +8615932307696

Site Web : www.delongfastener.com

E-mail: sales@delongfastener.com