Self-tapping screws have various names. They’re often called metal screws, sheet metal screws, tapping screws, or tapper screws. Their tips come in different shapes: pointed (like a pencil), blunt, or flat, and they are described as thread-forming, thread-cutting, or thread rolling. If the screw is pointed, it will be thread-cutting – tapping and creating threads in a pre-drilled hole. If the tip is flat, it is thread-rolling – rolling or extruding threads and creating zero clearance between screw and material.

When it comes to selecting the right self-tapping screw, it’s important to consider the material the screw will be used on. Different types of self-tapping screws are designed for specific materials, such as wood, metal, or plastic. The size and length of the screw should also be considered, as well as the desired level of torque, or tightening force, required for the application. Self-tapping screws are generally easy to install and can be used with a variety of tools, including power drills and screwdrivers. However, it’s important to note that over-tightening can cause the screw to strip the threads, reducing its holding power. It’s also important to ensure that the pilot hole, or hole that the screw is inserted into, is the correct size and shape to ensure proper thread formation and holding power.

The most important difference between self-tapping and self-drilling screws is that self-tapping screws cannot go through metal without a pilot hole, which must be pre-drilled or pre-punched. One of the main advantages of self-tapping screws is that they do not require pre-tapping, which is the process of creating threads in the material before inserting the screw. This eliminates the need for additional tools and can save time and labor costs. Additionally, self-tapping screws can be used in materials that are too thin or brittle to be pre-tapped, making them a versatile choice for a wide range of applications.

Exact drill or punch hole size is also important. The screw will become loose and not thread properly and securely if the hole’s too big. If the hole’s too small, the screw can break or cause the material to split or crack. Self-tapping screws are good for use with metals, various types of plastics (plywood, fiberglass, polycarbonates), and cast or forged material, like iron, aluminum, brass or bronze. Self-tapping screws also work for surfaces where you can’t secure the rear end with a nut. Common applications include fastening aluminum sections, attaching metal brackets onto wood, or inserting screws into plastic housings. In conclusion, self-tapping screws are a versatile and convenient option for creating threads in a variety of materials. They are easy to install and can save time and labor costs, making them a popular choice for many applications. By considering the material, size, length, and thread pattern of the screw, and by following proper installation techniques, you can ensure that your self-tapping screws will provide a secure and reliable hold.

- El día de la carga, el cliente visitó nuestra fábrica para inspeccionar su envío de tornillos autoperforantes.

- Nuestros clientes estaban complacidos de ver que todos nuestros productos eran de la más alta calidad con un tratamiento de superficie brillante.

- Los tornillos autoperforantes cincados están especialmente diseñados para resistir la corrosión y el óxido, lo que garantiza que permanezcan seguros y estables en cualquier entorno.

- Como empresa estamos comprometidos con la calidad del producto, por eso utilizamos los mejores materiales y la última tecnología para producir nuestros tornillos autoperforantes.

- En conclusión, nuestros visitantes quedaron impresionados con la inspección de su envío y quedaron muy satisfechos con la calidad y el empaque de nuestros productos.

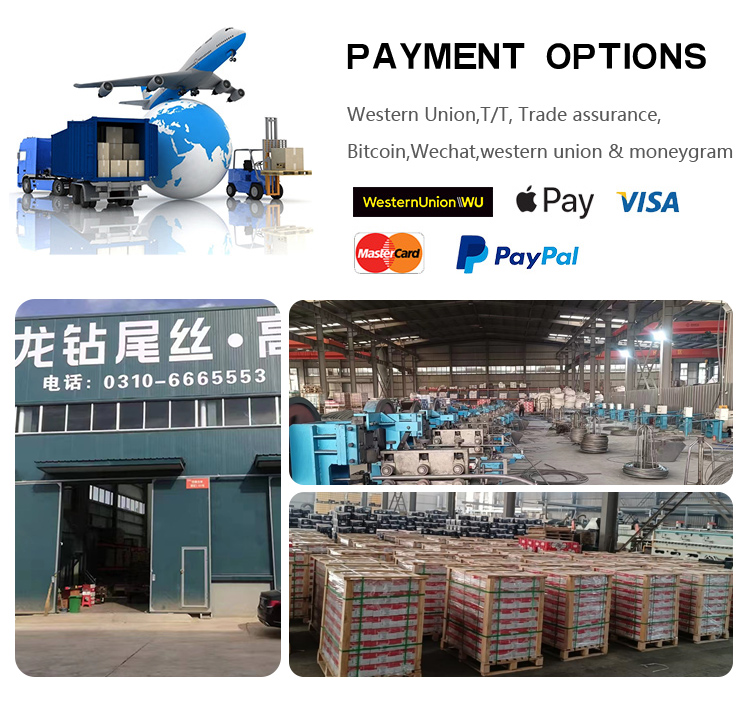

Hebei Delong Fastener Manufacturing Co., Ltd. está ubicada en el distrito de Yongnian, ciudad de Handan, provincia de Hebei, el centro de distribución de sujetadores. Está cerca de la autopista Beijing Zhuhai, el ferrocarril Beijing Guangzhou y la autopista nacional 107. Tiene un transporte conveniente y una ubicación geográfica superior.

Hebei Delong Fastener Manufacturing Co., Ltd. está ubicada en el distrito de Yongnian, ciudad de Handan, provincia de Hebei, el centro de distribución de sujetadores. Está cerca de la autopista Beijing Zhuhai, el ferrocarril Beijing Guangzhou y la autopista nacional 107. Tiene un transporte conveniente y una ubicación geográfica superior.

La empresa fue fundada en 2006. La empresa se centra en la I+D de elementos de fijación de alta gama, con una capacidad de producción anual de más de 8000 toneladas. Cuenta con equipos de producción, tecnología y equipos de tratamiento térmico de primera clase en Taiwán.

Gerente general: señor jin

TELÉFONO: 86-310-6665553

Móvil: +86 13703109255

¿Cuál es la aplicación: +8615932307696

Sitio web: www.delongfastener.com

Correo electrónico: sales@delongfastener.com