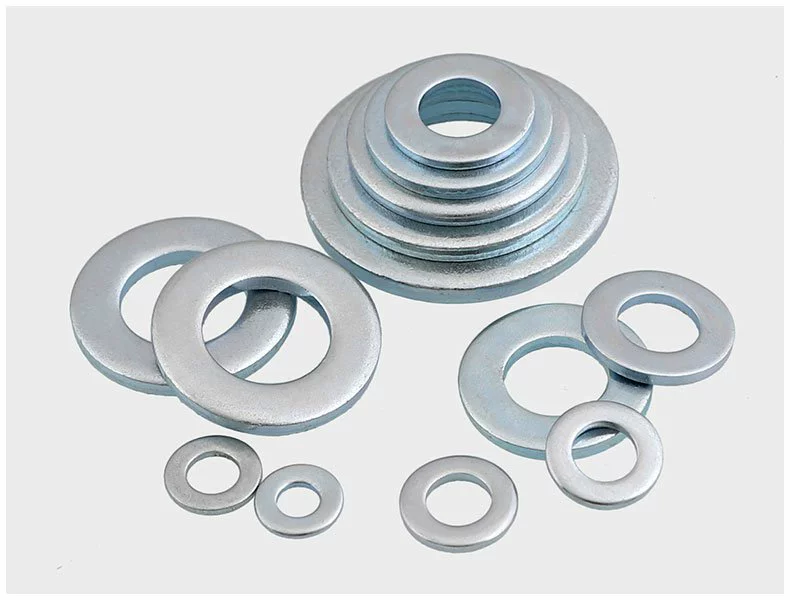

ARANDELAS

Screw washer is a small part placed between the screw head and the surface of the connected object, which is mainly used to disperse pressure, prevent looseness, reduce wear and protect the surface of the connected object.

Flat washer: Flat washer is the most common one, and its shape is a simple flat ring. Its main function is to increase the contact area between the screw head and the surface of the connected object, thus dispersing the pressure. For example, when using screws to fix soft materials (such as wood or plastic), the flat washer can prevent the screw head from directly pressing into the material, so that the pressure can be evenly distributed over a larger area of the washer and the material can be prevented from local deformation or damage.

Spring washer: the spring washer is spiral and looks like a small spring. Its main function is to provide elastic force to prevent the screw from loosening under vibration or dynamic load. It is often used in mechanical devices, automobile parts and various devices that need to withstand vibration. For example, in the connection of engine parts, the spring washer uses its own elasticity to continuously exert an axial elastic force after the screw is tightened, which increases the friction between the screw thread and the connected parts and effectively resists the loosening trend caused by engine vibration.

-

Las arandelas planas son una parte esencial de cualquier conjunto de sujetadores. Como sirven para incorporar espacios y distribuir la carga cuando se colocan entre una tuerca y un perno o tornillo, ayudarán a prevenir el desgaste y la distorsión de las superficies de instalación con el tiempo.

-

Arandela plana de alta resistencia para pernos de alta resistencia. La superficie sobre la que se asientan las arandelas no se hundirá. Estas arandelas evitan que los pernos se aflojen debido al hundimiento de la superficie en la que se asientan, etc.

-

Las arandelas elásticas son un subtipo de arandelas que tienen forma cónica para evitar que descansen al ras contra una superficie sin la presencia de una carga. Están diseñados para proporcionar una fuerza de resorte y absorber impactos proporcionando una carga axial que contrarresta las vibraciones. Como resultado, las arandelas elásticas pueden evitar drásticamente que los sujetadores se aflojen con el tiempo.

-

Las arandelas estructurales son de acero al carbono medio, tratadas térmicamente y endurecidas a 35-41 HRC. Las arandelas estructurales se utilizan con pernos estructurales y están diseñadas para conexiones estructurales de acero con acero, como edificios y construcción de puentes.

-

Las arandelas especiales tienen el mismo propósito que las arandelas estándar tradicionales, sin embargo, se definen por su forma irregular, ya sea no circular por dentro o por fuera.

-

Las arandelas de seguridad crean tensión al “bloquear” el perno o tornillo en el orificio roscado de la pieza de trabajo. A diferencia de las arandelas planas, tienen dientes en el cuerpo de la arandela para evitar la rotación y brindar una conexión más segura que las arandelas planas. Estas arandelas se utilizan con frecuencia en entornos de alta vibración para evitar que se afloje el conjunto de sujetadores.

-

Las arandelas elásticas DIN127 son un subtipo de arandelas que tienen forma cónica para evitar que descansen al ras contra una superficie sin la presencia de una carga. Están diseñados para proporcionar una fuerza de resorte y absorber impactos proporcionando una carga axial que contrarresta las vibraciones. Como resultado, las arandelas elásticas pueden evitar drásticamente que los sujetadores se aflojen con el tiempo.

-

DIN127 Spring washers are a subtype of washers that are conical in shape to prevent them from res

-

Las arandelas planas son una parte esencial de cualquier conjunto de sujetadores. Como sirven para incorporar espacios y distribuir la carga cuando se colocan entre una tuerca y un perno o tornillo, ayudarán a prevenir el desgaste y la distorsión de las superficies de instalación con el tiempo.

Material of Screw Washer

Screw washers are made of various materials. Flat washers can usually be made of carbon steel, stainless steel, copper and other materials. Carbon steel flat washers have low cost and high strength, and are suitable for general mechanical and building connections. Stainless steel flat washers have good corrosion resistance and are often used in outdoor environments or places with corrosion risks, such as marine facilities and chemical equipment. Copper gasket has good electrical and thermal conductivity and is used in some electrical equipment or connections that need good heat dissipation. Spring washers are generally made of spring steel, which is heat-treated to obtain the required elasticity and strength. The material of toothed washer also has a variety of choices, such as carbon steel and stainless steel, which are determined according to the specific application environment.

Key Points of Screw Washer Selection

When selecting the screw washer, the stress of the application scene should be considered first. If it is subjected to large axial pressure, it may be necessary to choose a thick and high-strength flat washer; For the environment with vibration, spring washer or toothed washer is a better choice. Secondly, the material characteristics of the connected objects should be considered. If it is a soft material, the hardness of the washer should not be too high to avoid crushing the material; For corrosive environment, choose the gasket material with good corrosion resistance. In addition, the size of the washer should match the specifications of the screw, the inner diameter of the washer should be slightly larger than the diameter of the screw, and the outer diameter should be determined according to the actual needs to ensure that the washer can function normally.

Mutual Cooperation Between Washer, Screw and Connected Object

Matching with the screw: the inner diameter of the washer is slightly larger than the diameter of the screw. Generally speaking, the inner diameter of the washer is about 0.1-0.3mm larger than the diameter of the screw, which can ensure that the washer can be smoothly sleeved on the screw without shaking on the screw. For screws with different heads, the choice of washers is also different.

For example, for flat head screws, the thickness of the washer should consider the thickness of the screw head to ensure good contact and pressure distribution between the screw head and the washer and the surface of the connected object after tightening; For hexagon-head screws, the washer can better match the plane of hexagon-head and effectively transmit torque during tightening.

Matching with the connected object: When selecting the gasket, the material hardness and surface roughness of the connected object should be considered. If the connected object is soft material, such as wood, rubber, etc., the hardness of the washer should not be too high to avoid damaging the material during tightening. For objects with rough surfaces, such as some metal castings that have not been finely machined, it may be necessary to choose washers with a slightly thicker thickness to make up for the influence caused by uneven surfaces.

At the same time, the outer diameter of the washer should be determined according to the size and connection requirements of the connected object, so as to ensure that the washer can completely cover the contact area between the screw head and the surface of the connected object, and give full play to its role of dispersing pressure and protecting the surface.