Self-tapping screws have various names. They’re often called metal screws, sheet metal screws, tapping screws, or tapper screws. Their tips come in different shapes: pointed (like a pencil), blunt, or flat, and they are described as thread-forming, thread-cutting, or thread rolling. If the screw is pointed, it will be thread-cutting – tapping and creating threads in a pre-drilled hole. If the tip is flat, it is thread-rolling – rolling or extruding threads and creating zero clearance between screw and material.

When it comes to selecting the right self-tapping screw, it’s important to consider the material the screw will be used on. Different types of self-tapping screws are designed for specific materials, such as wood, metal, or plastic. The size and length of the screw should also be considered, as well as the desired level of torque, or tightening force, required for the application. Self-tapping screws are generally easy to install and can be used with a variety of tools, including power drills and screwdrivers. However, it’s important to note that over-tightening can cause the screw to strip the threads, reducing its holding power. It’s also important to ensure that the pilot hole, or hole that the screw is inserted into, is the correct size and shape to ensure proper thread formation and holding power.

The most important difference between self-tapping and self-drilling screws is that self-tapping screws cannot go through metal without a pilot hole, which must be pre-drilled or pre-punched. One of the main advantages of self-tapping screws is that they do not require pre-tapping, which is the process of creating threads in the material before inserting the screw. This eliminates the need for additional tools and can save time and labor costs. Additionally, self-tapping screws can be used in materials that are too thin or brittle to be pre-tapped, making them a versatile choice for a wide range of applications.

Exact drill or punch hole size is also important. The screw will become loose and not thread properly and securely if the hole’s too big. If the hole’s too small, the screw can break or cause the material to split or crack. Self-tapping screws are good for use with metals, various types of plastics (plywood, fiberglass, polycarbonates), and cast or forged material, like iron, aluminum, brass or bronze. Self-tapping screws also work for surfaces where you can’t secure the rear end with a nut. Common applications include fastening aluminum sections, attaching metal brackets onto wood, or inserting screws into plastic housings. In conclusion, self-tapping screws are a versatile and convenient option for creating threads in a variety of materials. They are easy to install and can save time and labor costs, making them a popular choice for many applications. By considering the material, size, length, and thread pattern of the screw, and by following proper installation techniques, you can ensure that your self-tapping screws will provide a secure and reliable hold.

- On the loading day, customer visited our factory to inspect their shipment of self drilling screws.

- Our customers were pleased to see that all of our products were of the highest quality with a shining surface treatment.

- The zinc plated self drilling screws are specially designed to resist corrosion and rust, ensuring that they remain secure and stable in any environment.

- As a company, we are committed to product quality, and that is why we use the best materials and the latest technology to produce our self drilling screws.

- In conclusion, our visitors were impressed with their shipment inspection and were highly satisfied with the quality and packaging of our products.

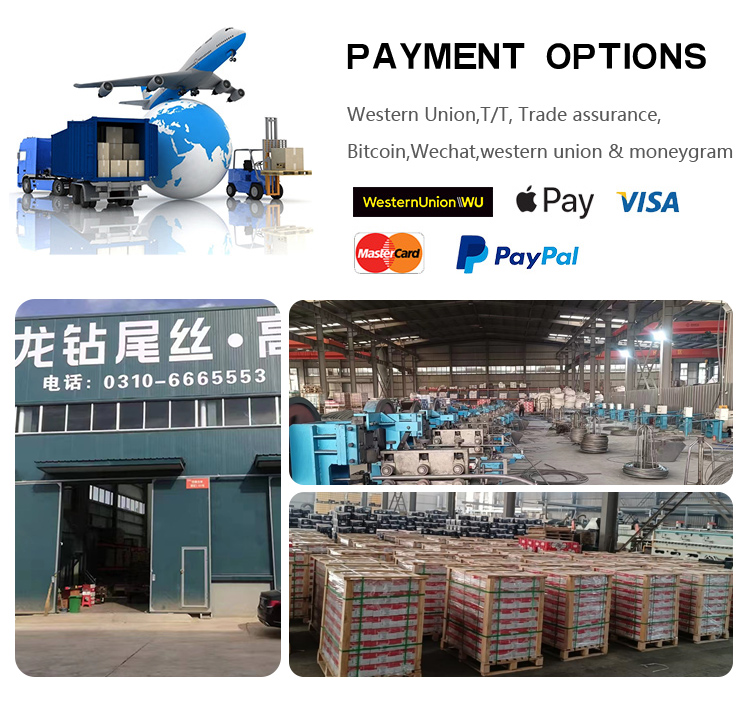

Hebei Delong Fastener Manufacturing Co., Ltd. is located in Yongnian District, Handan City, Hebei Province, the distribution center of fasteners. It is close to Beijing Zhuhai Expressway, Beijing Guangzhou railway and national highway 107. It has convenient transportation and superior geographical location.

Hebei Delong Fastener Manufacturing Co., Ltd. is located in Yongnian District, Handan City, Hebei Province, the distribution center of fasteners. It is close to Beijing Zhuhai Expressway, Beijing Guangzhou railway and national highway 107. It has convenient transportation and superior geographical location.

The company was founded in 2006. The company focuses on the R & D of high-end fasteners, with an annual production capacity of more than 8000 tons. It has first-class production equipment, technology and heat treatment equipment in Taiwan

General Manager: Mr Jin

TEL: 86-310-6665553

Mobile: +86 13703109255

Whats App: +8615932307696

Webstie: www.delongfastener.com

Email: sales@delongfastener.com