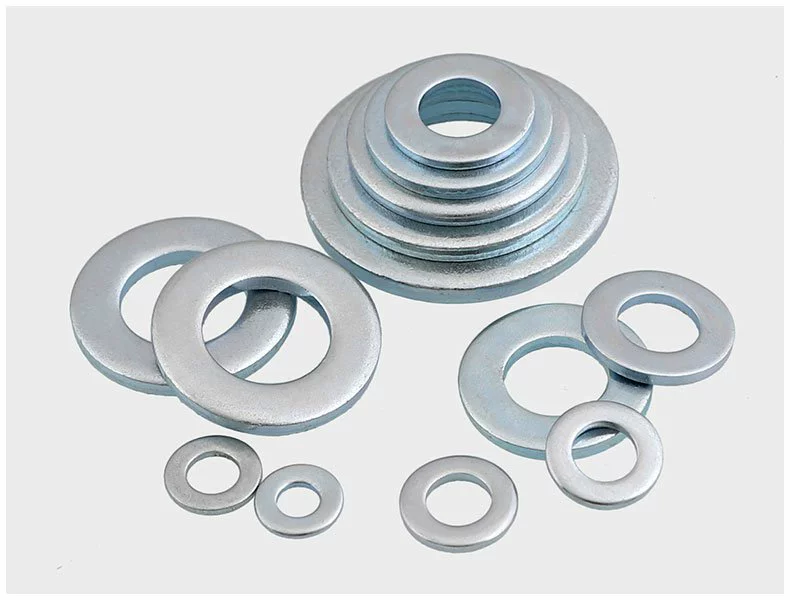

와셔

Screw washer is a small part placed between the screw head and the surface of the connected object, which is mainly used to disperse pressure, prevent looseness, reduce wear and protect the surface of the connected object.

Flat washer: Flat washer is the most common one, and its shape is a simple flat ring. Its main function is to increase the contact area between the screw head and the surface of the connected object, thus dispersing the pressure. For example, when using screws to fix soft materials (such as wood or plastic), the flat washer can prevent the screw head from directly pressing into the material, so that the pressure can be evenly distributed over a larger area of the washer and the material can be prevented from local deformation or damage.

Spring washer: the spring washer is spiral and looks like a small spring. Its main function is to provide elastic force to prevent the screw from loosening under vibration or dynamic load. It is often used in mechanical devices, automobile parts and various devices that need to withstand vibration. For example, in the connection of engine parts, the spring washer uses its own elasticity to continuously exert an axial elastic force after the screw is tightened, which increases the friction between the screw thread and the connected parts and effectively resists the loosening trend caused by engine vibration.

-

플랫 와셔는 모든 패스너 어셈블리의 필수 부품입니다. 너트와 볼트 또는 나사 사이에 배치할 때 간격을 통합하고 하중을 분산시키는 역할을 하므로 시간 경과에 따른 설치 표면의 마모 및 뒤틀림을 방지하는 데 도움이 됩니다.

-

고강도 볼트용 고강도 평와셔. 와셔가 있는 표면은 가라앉지 않습니다. 이 와셔는 볼트가 앉는 표면이 가라앉는 등으로 인해 볼트가 풀리는 것을 방지합니다.

-

스프링 와셔는 하중이 없는 상태에서 표면에 평평하게 놓이는 것을 방지하기 위해 모양이 원추형인 와셔의 하위 유형입니다. 진동에 대응하는 축방향 하중을 제공하여 스프링력을 제공하고 충격을 흡수하도록 설계되었습니다. 결과적으로 스프링 와셔는 패스너가 시간이 지남에 따라 느슨해지는 것을 크게 방지할 수 있습니다.

-

구조용 와셔는 중간 탄소강으로 열처리되고 35-41HRC로 경화됩니다. 구조용 와셔는 구조용 볼트와 함께 사용되며 건물 및 교량 건설과 같은 강철 간 구조 연결용으로 설계되었습니다.

-

특수 와셔는 기존의 표준 와셔와 동일한 목적을 가지고 있지만 내부 또는 외부가 비원형인 불규칙한 모양으로 정의됩니다.

-

잠금 와셔는 작업물의 나사산 구멍에 볼트나 나사를 "잠금"하여 장력을 생성합니다. 평와셔와 달리 와셔 본체에 톱니가 있어 회전을 방지하고 평와셔보다 더 안전한 연결을 제공합니다. 이 와셔는 패스너 어셈블리의 풀림을 방지하기 위해 진동이 심한 환경에서 자주 사용됩니다.

-

DIN127 스프링 와셔는 하중이 없는 상태에서 표면에 평평하게 놓이는 것을 방지하기 위해 모양이 원추형인 와셔의 하위 유형입니다. 진동에 대응하는 축방향 하중을 제공하여 스프링력을 제공하고 충격을 흡수하도록 설계되었습니다. 결과적으로 스프링 와셔는 패스너가 시간이 지남에 따라 느슨해지는 것을 크게 방지할 수 있습니다.

-

DIN127 Spring washers are a subtype of washers that are conical in shape to prevent them from res

-

플랫 와셔는 모든 패스너 어셈블리의 필수 부품입니다. 너트와 볼트 또는 나사 사이에 배치할 때 간격을 통합하고 하중을 분산시키는 역할을 하므로 시간 경과에 따른 설치 표면의 마모 및 뒤틀림을 방지하는 데 도움이 됩니다.

Material of Screw Washer

Screw washers are made of various materials. Flat washers can usually be made of carbon steel, stainless steel, copper and other materials. Carbon steel flat washers have low cost and high strength, and are suitable for general mechanical and building connections. Stainless steel flat washers have good corrosion resistance and are often used in outdoor environments or places with corrosion risks, such as marine facilities and chemical equipment. Copper gasket has good electrical and thermal conductivity and is used in some electrical equipment or connections that need good heat dissipation. Spring washers are generally made of spring steel, which is heat-treated to obtain the required elasticity and strength. The material of toothed washer also has a variety of choices, such as carbon steel and stainless steel, which are determined according to the specific application environment.

Key Points of Screw Washer Selection

When selecting the screw washer, the stress of the application scene should be considered first. If it is subjected to large axial pressure, it may be necessary to choose a thick and high-strength flat washer; For the environment with vibration, spring washer or toothed washer is a better choice. Secondly, the material characteristics of the connected objects should be considered. If it is a soft material, the hardness of the washer should not be too high to avoid crushing the material; For corrosive environment, choose the gasket material with good corrosion resistance. In addition, the size of the washer should match the specifications of the screw, the inner diameter of the washer should be slightly larger than the diameter of the screw, and the outer diameter should be determined according to the actual needs to ensure that the washer can function normally.

Mutual Cooperation Between Washer, Screw and Connected Object

Matching with the screw: the inner diameter of the washer is slightly larger than the diameter of the screw. Generally speaking, the inner diameter of the washer is about 0.1-0.3mm larger than the diameter of the screw, which can ensure that the washer can be smoothly sleeved on the screw without shaking on the screw. For screws with different heads, the choice of washers is also different.

For example, for flat head screws, the thickness of the washer should consider the thickness of the screw head to ensure good contact and pressure distribution between the screw head and the washer and the surface of the connected object after tightening; For hexagon-head screws, the washer can better match the plane of hexagon-head and effectively transmit torque during tightening.

Matching with the connected object: When selecting the gasket, the material hardness and surface roughness of the connected object should be considered. If the connected object is soft material, such as wood, rubber, etc., the hardness of the washer should not be too high to avoid damaging the material during tightening. For objects with rough surfaces, such as some metal castings that have not been finely machined, it may be necessary to choose washers with a slightly thicker thickness to make up for the influence caused by uneven surfaces.

At the same time, the outer diameter of the washer should be determined according to the size and connection requirements of the connected object, so as to ensure that the washer can completely cover the contact area between the screw head and the surface of the connected object, and give full play to its role of dispersing pressure and protecting the surface.