Feb . 10, 2025 11:11

Back to list

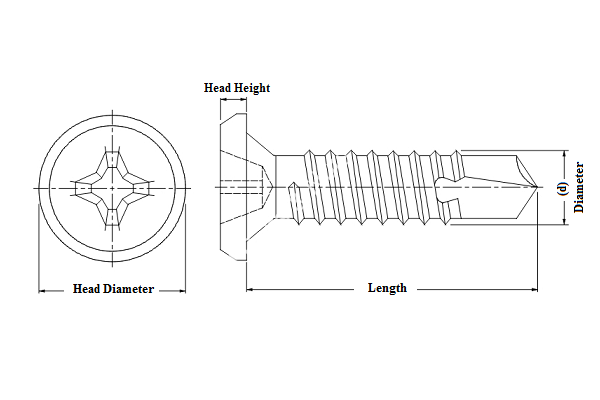

8 self tapping screw dimensions

Self-tapping screws are versatile fasteners widely used in construction, woodworking, automotive, and electronics industries. These screws are designed to tap their own threads into materials like metal, plastic, and wood, eliminating the need for pre-drilled holes or nuts. Understanding the dimensions of self-tapping screws is crucial for ensuring the structural integrity and functionality of a project.

Precision in matching the screw dimensions with the application is paramount. Using a screw with incorrect measurements can lead to issues such as poor holding performance, material damage, or even structural failure. By paying close attention to the specifics of diameter, length, head style, thread type, material, and finish, users can ensure the effective implementation of self-tapping screws in their projects. Moreover, it's prudent to rely on established best practices from the construction or technical industries. Seeking advice from professionals or referencing the technical specifications provided by reputable manufacturers can provide insights into selecting the appropriate self-tapping screw dimensions. Industry Experience Journeymen and experienced technicians frequently emphasize the importance of not underestimating the significance of screw dimensions. Through trial and experience, the consistent advice stresses understanding material compatibility and ensuring that the screw can handle the physical stresses of the application without compromising integrity. Expertise Engineers often conduct meticulous assessments to determine the precise requirements for fastening applications. For example, in the automotive industry, engineers select screws not just based on mechanical properties but also considering vibrational impacts and long-term wear. Authoritativeness Leading manufacturers and technical bodies provide extensive guides and white papers regarding fastener selections. Companies like Fastenal and organizations like the American Society of Mechanical Engineers (ASME) have set standards and guidelines that serve as trusted sources for selecting appropriate self-tapping screw dimensions. Trustworthiness Users should adhere to information sourced from certified experts and peer-reviewed studies. Rigorous testing and certification ensure that selected screws will perform as expected in their designated applications, thereby instilling confidence in their use. By considering these factors and tapping into the wealth of industry knowledge, users can make well-informed choices regarding self-tapping screw dimensions, ultimately enhancing the quality and safety of their projects.

Precision in matching the screw dimensions with the application is paramount. Using a screw with incorrect measurements can lead to issues such as poor holding performance, material damage, or even structural failure. By paying close attention to the specifics of diameter, length, head style, thread type, material, and finish, users can ensure the effective implementation of self-tapping screws in their projects. Moreover, it's prudent to rely on established best practices from the construction or technical industries. Seeking advice from professionals or referencing the technical specifications provided by reputable manufacturers can provide insights into selecting the appropriate self-tapping screw dimensions. Industry Experience Journeymen and experienced technicians frequently emphasize the importance of not underestimating the significance of screw dimensions. Through trial and experience, the consistent advice stresses understanding material compatibility and ensuring that the screw can handle the physical stresses of the application without compromising integrity. Expertise Engineers often conduct meticulous assessments to determine the precise requirements for fastening applications. For example, in the automotive industry, engineers select screws not just based on mechanical properties but also considering vibrational impacts and long-term wear. Authoritativeness Leading manufacturers and technical bodies provide extensive guides and white papers regarding fastener selections. Companies like Fastenal and organizations like the American Society of Mechanical Engineers (ASME) have set standards and guidelines that serve as trusted sources for selecting appropriate self-tapping screw dimensions. Trustworthiness Users should adhere to information sourced from certified experts and peer-reviewed studies. Rigorous testing and certification ensure that selected screws will perform as expected in their designated applications, thereby instilling confidence in their use. By considering these factors and tapping into the wealth of industry knowledge, users can make well-informed choices regarding self-tapping screw dimensions, ultimately enhancing the quality and safety of their projects.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News