2 月 . 11, 2025 16:40

Back to list

no 6 self tapping screw dimensions

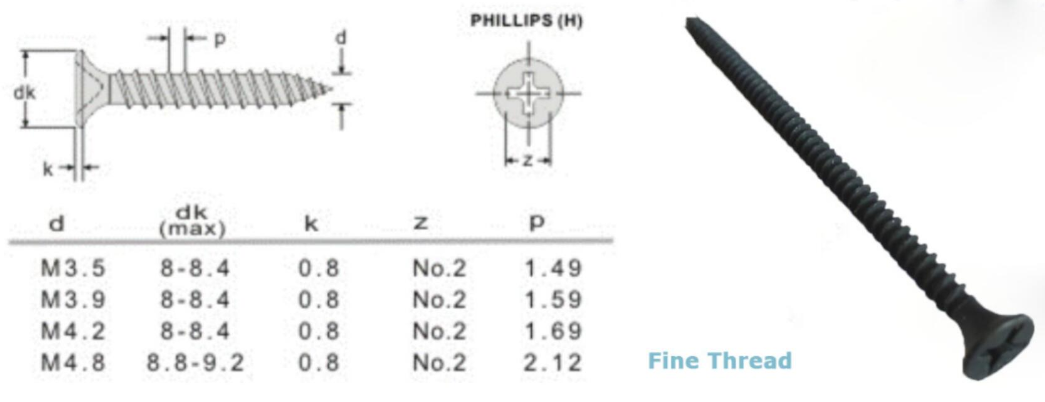

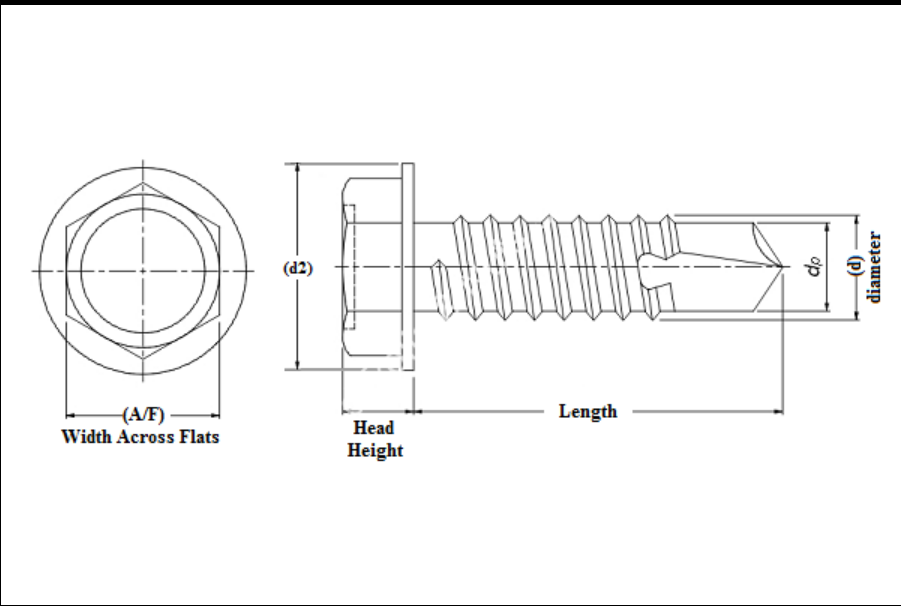

Selecting the right self-tapping screw for your project can significantly enhance the structural integrity and longevity of your build. When it comes to No. 6 self-tapping screws, understanding their dimensions and applications is paramount. These screws are the unsung heroes of the mechanical world, quietly ensuring that various components hold together securely.

It's also important to consider the material from which the screw is made. Stainless steel is an excellent choice for applications exposed to moisture because of its corrosion resistance. Zinc-plated variants, on the other hand, offer a more economical option for indoor uses, where the threat of rust is minimized. For high-stress environments, hardened steel screws can withstand greater forces without shearing. From an authoritativeness perspective, manufacturers seldom follow a strict formula for packaging these screws, and it's essential to ensure the product meets recognized standards, such as those from the American Society for Testing and Materials (ASTM). Choosing screws marked with such certifications ensures that they have gone through rigorous testing for quality and reliability. Drawing from real-world experiences, many veteran carpenters and builders praise the versatility of No. 6 screws. Their adaptability in various settings—be it securing metal roofing panels, assembling wood cabinetry, or piecing together automotive interiors—demonstrates their indispensable role in different sectors. Users often share anecdotes of using these screws to solve unexpected challenges in DIY projects, thanks to their ease of use and reliability. In conclusion, understanding the dimensions and specifications of No. 6 self-tapping screws not only improves your selection process but also contributes significantly to the success of your project. Whether you are securing panels on a custom bookshelf or stitching together the underbelly of a light aircraft, selecting the correct screw with the right specifications is crucial. As you choose the perfect screw for your next venture, these insights provide a roadmap to make informed decisions that enhance both the craftsmanship and durability of your work.

It's also important to consider the material from which the screw is made. Stainless steel is an excellent choice for applications exposed to moisture because of its corrosion resistance. Zinc-plated variants, on the other hand, offer a more economical option for indoor uses, where the threat of rust is minimized. For high-stress environments, hardened steel screws can withstand greater forces without shearing. From an authoritativeness perspective, manufacturers seldom follow a strict formula for packaging these screws, and it's essential to ensure the product meets recognized standards, such as those from the American Society for Testing and Materials (ASTM). Choosing screws marked with such certifications ensures that they have gone through rigorous testing for quality and reliability. Drawing from real-world experiences, many veteran carpenters and builders praise the versatility of No. 6 screws. Their adaptability in various settings—be it securing metal roofing panels, assembling wood cabinetry, or piecing together automotive interiors—demonstrates their indispensable role in different sectors. Users often share anecdotes of using these screws to solve unexpected challenges in DIY projects, thanks to their ease of use and reliability. In conclusion, understanding the dimensions and specifications of No. 6 self-tapping screws not only improves your selection process but also contributes significantly to the success of your project. Whether you are securing panels on a custom bookshelf or stitching together the underbelly of a light aircraft, selecting the correct screw with the right specifications is crucial. As you choose the perfect screw for your next venture, these insights provide a roadmap to make informed decisions that enhance both the craftsmanship and durability of your work.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News