oem m8 self tapping screw

The Versatility and Importance of OEM M8 Self-Tapping Screws

In the realm of hardware and construction, the importance of reliable fasteners cannot be overstated. Among these, OEM M8 self-tapping screws stand out for their versatility and reliability in various applications. Whether in automotive manufacturing, electronics, or general construction, these screws provide essential functions that enhance the durability and structural integrity of assembled products.

What Are OEM M8 Self-Tapping Screws?

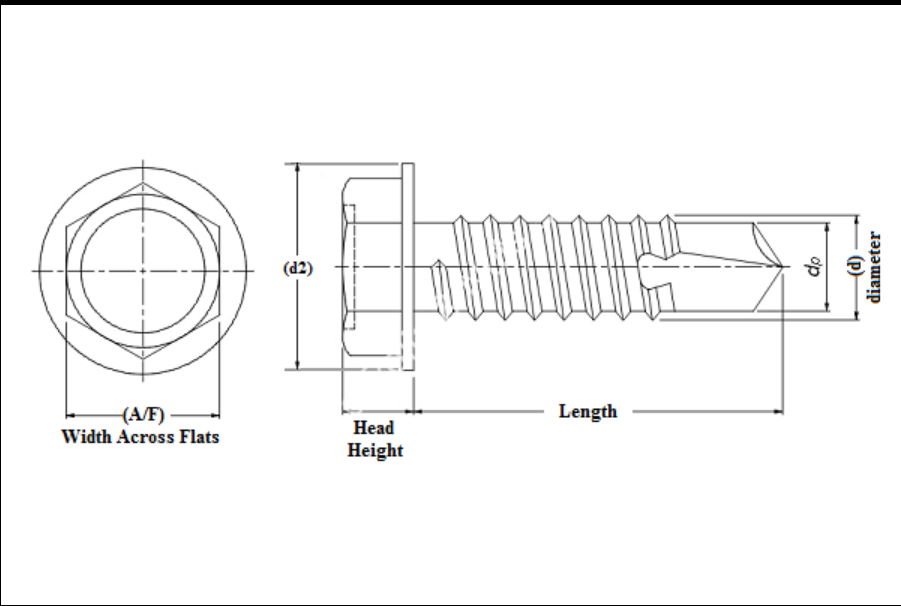

OEM, or Original Equipment Manufacturer, refers to products that are produced by a company to be used in the products of another company. M8 refers to the metric screw size, indicating a nominal diameter of 8 mm. Self-tapping screws, on the other hand, are designed for their unique capability to create their own mating thread as they are driven into material, which eliminates the need for pre-drilled holes in many applications.

The M8 size is particularly popular for its balanced dimensions, making it suitable for both light-duty and heavy-duty applications. The combination of these elements means that OEM M8 self-tapping screws can provide effective solutions for a variety of fastening needs.

Advantages of M8 Self-Tapping Screws

1. Ease of Use One of the primary advantages of self-tapping screws is their ease of installation. Users do not need to perform additional drilling, which saves time and labor costs. This feature is particularly beneficial in environments where speed and efficiency are critical.

2. Strong Hold The ability of self-tapping screws to create their own threads in various materials, such as metal, plastic, and wood, means they can establish a strong hold. This is essential in applications where vibration or movement may otherwise loosen conventional screws.

3. Versatility M8 self-tapping screws can be used in a wide range of applications. From automotive assembly to construction of furniture and electronic devices, their adaptability makes them highly valued. They can accommodate various materials and thicknesses, making them a go-to fastener for many industries.

oem m8 self tapping screw

4. Cost-Efficiency Given the reduction in labor and time associated with their use, M8 self-tapping screws can be more cost-effective compared to traditional fastening methods. Additionally, they are widely available, which can help businesses manage costs effectively.

5. Variety of Types and Coatings OEM M8 self-tapping screws come in various head types, including pan, flat, and hex, allowing users to select the best option for their application. Furthermore, they can be coated to enhance corrosion resistance, which is vital in outdoor or industrial environments.

Applications in Various Industries

The applications of M8 self-tapping screws stretch across multiple sectors

- Automotive Industry Self-tapping screws are crucial in automobile manufacturing, where they hold components together under demanding conditions. These screws ensure that parts remain secure, even amidst constant vibration and potential impact.

- Construction In the construction sector, M8 screws can be employed in framing, roofing, and other structural elements. Their ability to hold materials securely makes them essential in ensuring the safety and longevity of buildings.

- Electronics In electronics, these screws are often used to assemble devices where space is limited but strength is still necessary. They can securely attach casings and internal components.

Conclusion

OEM M8 self-tapping screws epitomize the blend of practicality and innovation in the world of fasteners. Their ease of use, strength, and versatility make them a preferred choice for various applications across different industries. As technology continues to evolve and industries demand higher performance from their materials, the importance of reliable fastening solutions like M8 self-tapping screws will only increase. Understanding their properties and applications can empower businesses to select the right fastener for their needs, ensuring that they maintain quality and efficiency in their production processes.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024