Hex Head Self-Drilling Screw Manufacturer for Reliable Construction Solutions

Understanding Self-Drilling Screw Hex Head Manufacturers

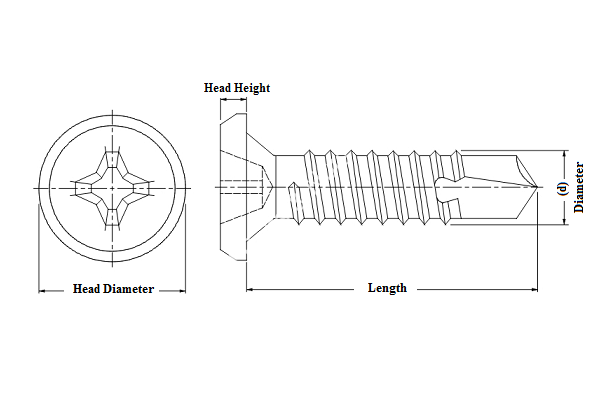

Self-drilling screws, particularly those with hex heads, play a crucial role in various construction and manufacturing applications. These screws are designed to drill their own pilot holes, making them highly efficient and reliable for securing materials without the need for pre-drilling. The hex head feature allows for better torque application with a wrench or socket, providing a more reliable grip during installation. In this article, we will explore the significance of self-drilling screw hex head manufacturers, the advantages of their products, and factors to consider when selecting a supplier.

The Significance of Self-Drilling Screws

Self-drilling screws are particularly valued in the construction industry for their time-saving benefits. Traditionally, fastening materials involved two steps drilling a pilot hole and then driving in a screw. However, self-drilling screws eliminate the need for the first step, which not only saves time but also reduces labor costs. Their unique design features a drill bit tip that allows the screw to penetrate various materials, including wood, metal, and plastic, with ease.

Hex head screws are a specific type of self-drilling screw that boasts a hexagonal shape, enabling the use of a wrench for installation. This design provides a more substantial grip and helps prevent stripping, which is often a concern with traditional screw heads. The ability to use power tools for installation also means that these screws can be driven in quickly and securely, making them ideal for projects that require efficiency and high productivity.

Advantages of Self-Drilling Screws with Hex Heads

1. Self-Drilling Capability The drill tip incorporates a cutting edge, which allows the screw to create its own hole, providing a significant time-saving advantage during installation.

2. Versatility These screws can be used in a variety of materials, including steel, aluminum, and wood, making them suitable for diverse applications ranging from roofing to metal fabrication.

3. Strong Torque Application The hex head design facilitates the use of higher torque without the risk of stripping. This is essential for applications requiring strong fastening, particularly in metal construction.

4. Corrosion Resistance Many self-drilling screws are available with coatings or treatments that enhance their corrosion resistance. This is particularly advantageous in outdoor or harsh environments where durability is critical.

self drilling screw hex head manufacturer

Choosing a Self-Drilling Screw Hex Head Manufacturer

When selecting a self-drilling screw hex head manufacturer, there are several factors to consider

1. Quality of Materials Ensure that the manufacturer uses high-quality materials for their screws. This includes using carbon steel, stainless steel, or other alloys that meet industry standards for strength and durability.

2. Manufacturing Standards Look for manufacturers that adhere to quality control standards such as ISO certification. This ensures that the products meet specific quality thresholds and are reliable for various applications.

3. Product Range A reputable manufacturer should offer a wide range of self-drilling screws with various specifications. This includes different sizes, coatings, and thread designs to meet diverse needs.

4. Customer Service Good customer support can make a significant difference in your purchasing experience. A manufacturer that provides assistance with product selection, order tracking, and timely delivery is preferable.

5. Industry Experience Consider the manufacturer's experience in the industry. Established manufacturers with a strong track record are typically better able to meet your needs and deliver quality products.

Conclusion

Self-drilling screws with hex heads have become an essential component in modern construction and manufacturing processes. Their efficiency, versatility, and durability make them a preferred choice among builders and manufacturers alike. When choosing a self-drilling screw hex head manufacturer, it's crucial to consider factors such as material quality, manufacturing standards, product range, customer service, and industry experience. By making informed decisions, businesses can ensure they are selecting the best screws for their specific applications while building lasting relationships with reliable manufacturers.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024