Jan . 21, 2025 02:58

Back to list

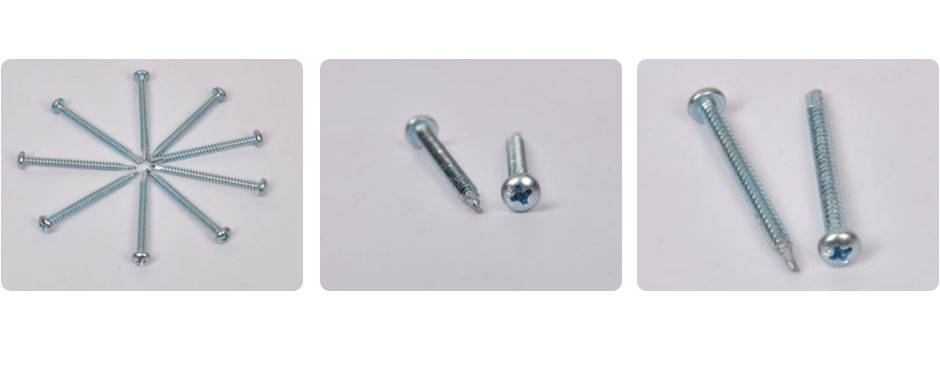

csk head self tapping screw

In a world where construction and DIY projects demand both efficiency and durability, self tapping screws have emerged as a vital component. These versatile fasteners not only simplify assembly processes but also ensure secure and lasting connections. For the uninitiated, a self tapping screw is designed to drill its own pilot hole as it penetrates the material. This attribute eliminates the need for pre-drilling, thereby saving time and reducing labor costs.

The authoritative advantage of self tapping screws is evident in engineering and construction manuals, which often recommend them for applications requiring reliable, repetitive, and high-load connections. They're routinely used in the automotive and aerospace industries, where secure fastening solutions are critical. In terms of trustworthiness, reputable manufacturers provide detailed specifications, including tensile strength, shear strength, and torque requirements, ensuring that the user is well-informed about the capabilities and limitations of their products. This transparency fosters confidence and allows users to make informed decisions about the appropriate fastener for their specific needs. Moreover, the installation of self tapping screws isn't limited to professionals. With the correct tools and a basic understanding, DIY enthusiasts can easily utilize these screws to execute projects with professional results. A variable speed drill equipped with the correct driver bit can facilitate smooth insertion, eliminating the risk of over-tightening or damaging the material. In conclusion, self tapping screws epitomize the fusion of innovation and functionality. They are engineered to suit diverse applications, from residential to industrial settings. Their capacity to facilitate self-sufficient assembly processes while maintaining superior holding capabilities underscores their indispensable role in modern construction and manufacturing. By choosing the right type and size, users can unlock the full potential of self tapping screws, paving the way for projects that are robust, reliable, and built to last.

The authoritative advantage of self tapping screws is evident in engineering and construction manuals, which often recommend them for applications requiring reliable, repetitive, and high-load connections. They're routinely used in the automotive and aerospace industries, where secure fastening solutions are critical. In terms of trustworthiness, reputable manufacturers provide detailed specifications, including tensile strength, shear strength, and torque requirements, ensuring that the user is well-informed about the capabilities and limitations of their products. This transparency fosters confidence and allows users to make informed decisions about the appropriate fastener for their specific needs. Moreover, the installation of self tapping screws isn't limited to professionals. With the correct tools and a basic understanding, DIY enthusiasts can easily utilize these screws to execute projects with professional results. A variable speed drill equipped with the correct driver bit can facilitate smooth insertion, eliminating the risk of over-tightening or damaging the material. In conclusion, self tapping screws epitomize the fusion of innovation and functionality. They are engineered to suit diverse applications, from residential to industrial settings. Their capacity to facilitate self-sufficient assembly processes while maintaining superior holding capabilities underscores their indispensable role in modern construction and manufacturing. By choosing the right type and size, users can unlock the full potential of self tapping screws, paving the way for projects that are robust, reliable, and built to last.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News