oem spring washer din127 m27

Understanding OEM Spring Washers A Focus on DIN 127 M27

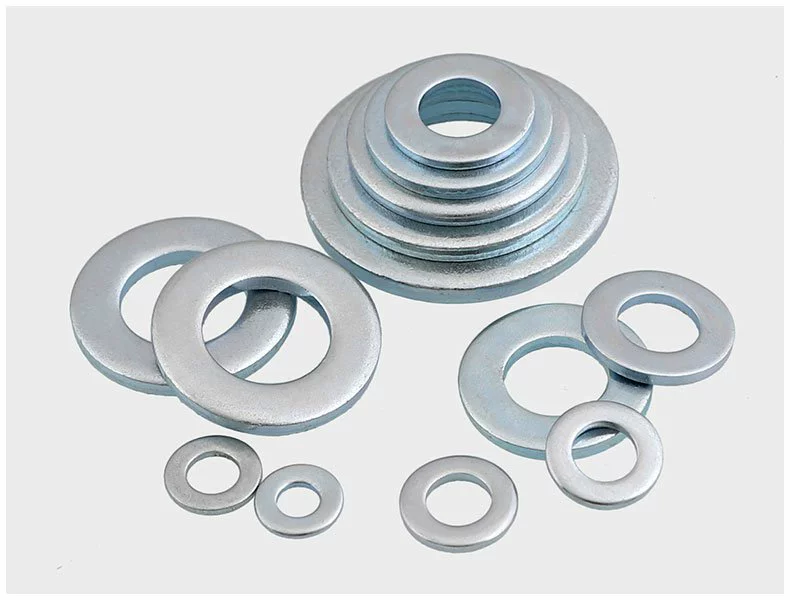

When it comes to securing components in machinery and structural applications, spring washers play an essential role. Among the various standards and types of spring washers, the DIN 127 M27 is notable, particularly in the context of Original Equipment Manufacturer (OEM) practices. This article delves into the features, applications, and manufacturing considerations for OEM spring washers, specifically focusing on the DIN 127 M27 variant.

What is a Spring Washer?

A spring washer is a type of fastener that applies a spring force, providing resistance against loosening, vibration, and material fatigue in assembled components. They are typically made from resilient materials, such as steel or stainless steel, and are designed to maintain tension between joined parts. This capability makes them indispensable in automotive, aerospace, industrial machinery, and construction sectors.

The DIN 127 Standard

The DIN 127 standard is a German standard that outlines the specifications for bent spring washers. These washers are characterized by their unique shape, featuring a conical structure that allows them to exert constant pressure against clamped components. The most recognizable feature of the DIN 127 spring washer is its ability to maintain tension within a joint, which is crucial in applications involving dynamic loads.

M27 Specifications

The M27 designation refers to the size of the spring washer. This indicates that the washer is intended to fit M27 bolts or screws, which have a nominal diameter of 27 millimeters. The dimensions of the DIN 127 M27 spring washer ensure optimal compatibility with M27 fasteners, promoting effective load distribution and enhancing joint integrity.

Applications of DIN 127 M27 Spring Washers

The DIN 127 M27 spring washer finds its applications in various industries. Its robustness makes it suitable for

1. Automotive Industry In vehicles, maintaining tight connections is vital due to the constant vibrations caused by engine operation. M27 spring washers help prevent bolts and other fasteners from loosening over time.

oem spring washer din127 m27

3. Machinery In industrial machinery, the washers assist in maintaining the stability of moving parts, effectively managing the impact of various forces.

4. Aerospace Aerospace applications demand components that can endure extreme conditions. M27 spring washers contribute to the reliability and safety of machinery and aircraft systems.

OEM Considerations

For Original Equipment Manufacturers, choosing the right spring washer is crucial for the overall quality and reliability of their products. When sourcing DIN 127 M27 spring washers, OEMs should consider the following

1. Material Quality Select washers made from high-grade materials, such as hardened steel or stainless steel, to ensure strength, corrosion resistance, and durability.

2. Manufacturing Precision OEMs should work with manufacturers that adhere to strict quality standards and can provide the necessary certifications. A washer that meets the DIN 127 specifications will ensure consistent performance.

3. Supplier Reliability Establishing a relationship with a trustworthy supplier is essential. They should offer assistance with inventory management and be able to deliver timely shipments to minimize production downtime.

4. Performance Testing Before integrating the washers into their products, OEMs may conduct testing to ensure that the washers perform under expected conditions and stresses.

Conclusion

The DIN 127 M27 spring washer is more than just a simple component; it is a vital element in ensuring the reliability and safety of various applications within different industries. For OEMs, understanding the importance of using the right washers can lead to enhanced product performance and customer satisfaction. As industries evolve, the demand for high-quality OEM spring washers like the DIN 127 M27 will continue to grow, underscoring the necessity for proper selection and supplier partnerships. By prioritizing quality and adherence to standards, manufacturers can significantly elevate their products in a competitive market.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024