oem 10 self tapping screw drill size

Understanding OEM 2010 Self-Tapping Screw Drill Size

Self-tapping screws are a vital component in many industries, from automotive to construction, providing a secure fastening solution without the need for pre-drilled holes. In the realm of Original Equipment Manufacturing (OEM), understanding the appropriate drill size for these screws is crucial for ensuring that they function as intended. This article delves into the specifics of OEM 2010 self-tapping screws, focusing on drill sizes, their importance, and considerations for selecting the right size.

What Are Self-Tapping Screws?

Self-tapping screws are designed to tap their own threads as they are driven into a material, creating a tight connection that is resistant to loosening and stripping. These screws come in various sizes, materials, and thread types, making them versatile for a wide range of applications. In many cases, they are used in metalworking and woodworking, where achieving a solid grip is essential.

Importance of Drill Size

Choosing the correct drill size for self-tapping screws is crucial because it affects the screw's ability to create threads in the material being fastened. If the drill hole is too small, it can lead to excessive pressure on the screw, increasing the likelihood of stripping the threads or breaking the screw. Conversely, a hole that is too large may not allow the screw to grip effectively, resulting in a weak connection that can lead to structural failure.

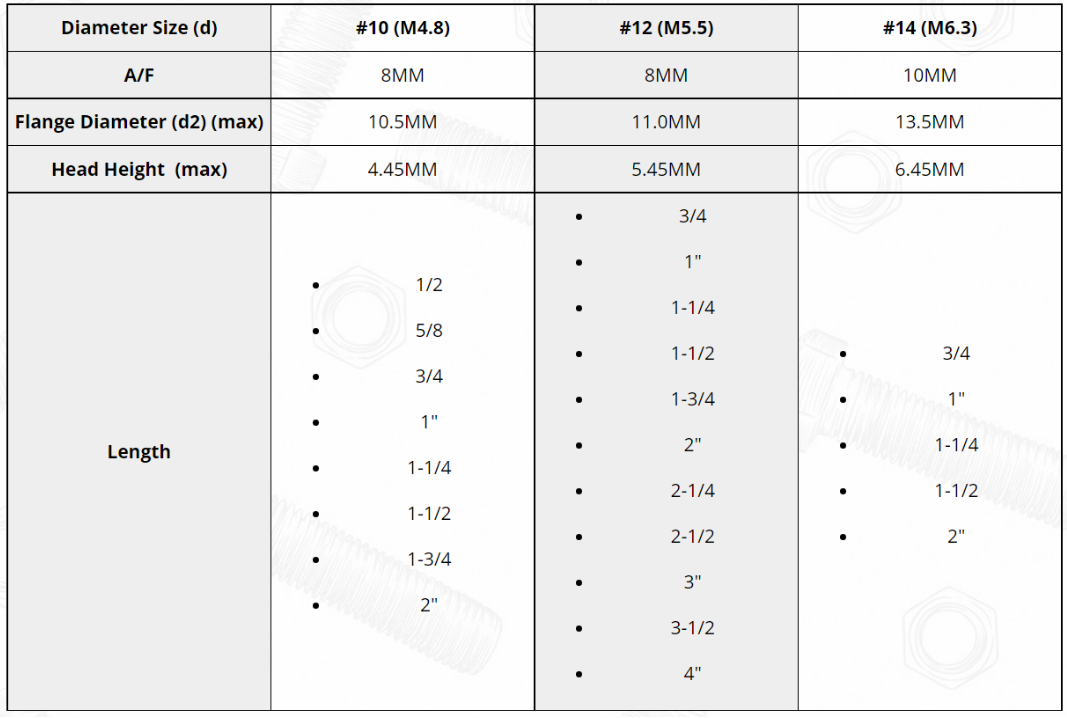

The drill size needed for OEM 2010 self-tapping screws varies depending on the screw's diameter and thread specifications. OEM standards provide guidelines on the appropriate drill sizes to achieve optimal performance.

OEM 2010 Specifications

The OEM 2010 standard outlines specific requirements for self-tapping screws utilized in various applications. This standard includes dimensions, materials, and performance criteria that screws must meet to ensure quality and reliability. When adhering to OEM standards, manufacturers can ensure that their products are compatible, functional, and maintain a level of quality expected in the industry.

oem 10 self tapping screw drill size

For self-tapping screws, the drill size is typically determined by the screw's diameter. The general rule of thumb is that the drill bit should be slightly smaller than the screw’s major diameter, allowing the threads to form properly without overly compromising the surrounding material.

Selecting the Right Drill Size

When selecting the drill size for OEM 2010 self-tapping screws, the following factors should be considered

1. Screw Diameter The diameter of the screw is the most critical factor. Different sizes of screws require different drill bit sizes. For instance, a 8 screw typically requires a drill bit of 0.19 inches, while a 10 screw may need around 0.19-0.20 inches.

2. Material Type The material into which the screw will be driven also influences the drill size choice. Softer materials, like plastic or softer woods, may require different considerations than harder materials like metal or hardwood.

3. Thread Type Self-tapping screws come with various thread types (e.g., coarse, fine), which will affect the drilling parameters. Coarse threads typically require a slightly larger pilot hole compared to fine threads.

4. Depth of Screw The overall length of the screw can also dictate drill size. Certain applications may require deeper holes to accommodate longer screws effectively.

Conclusion

In conclusion, selecting the correct drill size for OEM 2010 self-tapping screws is a critical step in ensuring the success and integrity of fastening applications. Understanding the specifications set forth by OEM standards allows manufacturers and technicians to make informed decisions that contribute to the quality and durability of their products. By considering factors such as screw diameter, material type, thread type, and screw depth, one can optimize the fastening process and enhance overall efficiency. When it comes to engineering and manufacturing, attention to detail in every aspect, including drill size selection, plays an indispensable role in achieving high-quality results.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024