flat head phillips self drilling screw pricelist

Understanding Flat Head Phillips Self-Drilling Screw Price Lists

When it comes to construction and manufacturing, finding the right fasteners is crucial. One commonly used type of fastener is the self-drilling screw, specifically the flat head Phillips self-drilling screw. These screws are designed to create their own hole in the material they are driving into, which significantly reduces the need for pre-drilling, making them a preferred choice in various applications. In this article, we will explore the significance of these screws, their features, and how to interpret their price lists effectively.

What are Flat Head Phillips Self-Drilling Screws?

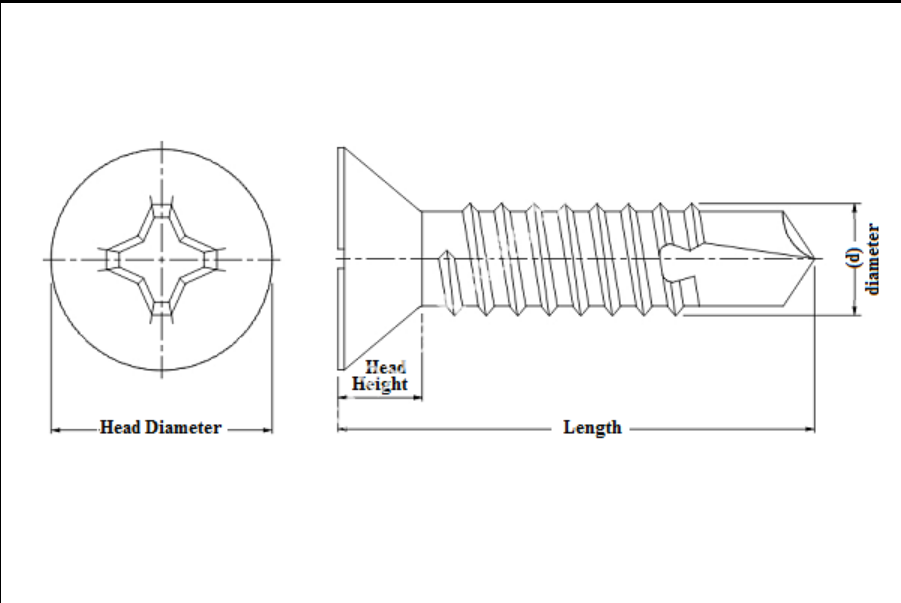

Flat head Phillips self-drilling screws have a unique design characterized by a flat head and a Phillips drive, which is a cross-shaped socket designed for Phillips screwdrivers. The self-drilling feature means these screws come with a sharp, pointed tip that allows them to penetrate materials like wood, metal, and plastic directly without needing a pre-drilled hole. This capability not only saves time but also enhances the strength of the joint since drilling and tapping occur in one motion.

Applications of Self-Drilling Screws

These screws are widely used in various industries, including construction, automotive, and manufacturing. They are ideal for attaching metal to metal, securing roofing and siding materials, and fastening various components in machinery. Their ability to easily penetrate tough materials makes them a go-to option for contractors looking for efficiency and durability.

Factors Influencing the Price of Self-Drilling Screws

When examining a price list for flat head Phillips self-drilling screws, several factors can influence pricing

1. Material The material of the screw affects its cost. Screws made of stainless steel are more expensive than those made of carbon steel due to their rust resistance and added durability.

2. Coating Many self-drilling screws come with protective coatings, such as zinc or epoxy, to prevent corrosion. These coatings increase manufacturing costs, which can be reflected in the price.

flat head phillips self drilling screw pricelist

3. Size and Gauge The length and thickness (gauge) of the screws also play a role in determining their cost. Larger and thicker screws generally require more material and processing, leading to higher prices.

4. Quantity Purchasing in bulk can often reduce the per-unit cost significantly. Many suppliers offer discounts on larger orders, making it more economical for contractors and businesses to stock up.

5. Brand The reputation of the manufacturer can also influence prices. Established brands may charge more due to perceived quality and reliability.

How to Read a Price List

When evaluating a price list for flat head Phillips self-drilling screws, buyers should

- Look for Specifications Ensure that the specifications match your project needs in terms of size, material, and coating. - Compare Pricing Analyze different suppliers to find competitive prices while assessing quality standards. - Consider Shipping and Handling Factor in any additional costs such as shipping, especially for bulk orders, as they can significantly affect the total expenditure.

- Review Warranty and Quality Assurance Quality screws often come with warranties or guarantees which may justify a higher price.

Conclusion

Flat head Phillips self-drilling screws are essential components in various applications, valued for their ease of use and efficiency. Understanding the factors that influence their pricing and how to interpret price lists can help buyers make informed purchasing decisions. Whether you are a contractor, manufacturer, or DIY enthusiast, being equipped with the right knowledge about these screws and their pricing can lead to better project outcomes and cost-effectiveness. As construction methods evolve, reliable fasteners like the flat head Phillips self-drilling screw will continue to play a vital role in the industry.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024