supply pan head self drilling screw exporters exporter

The Rising Demand for Supply of Pan Head Self-Drilling Screws A Look into Export Markets

In recent years, the construction and manufacturing industries have seen a noteworthy surge in the demand for various fastening solutions. Among these, pan head self-drilling screws have emerged as a critical component due to their unique design and functionality. This article explores the characteristics of pan head self-drilling screws, their applications, and the landscape of exporters in the global market.

Understanding Pan Head Self-Drilling Screws

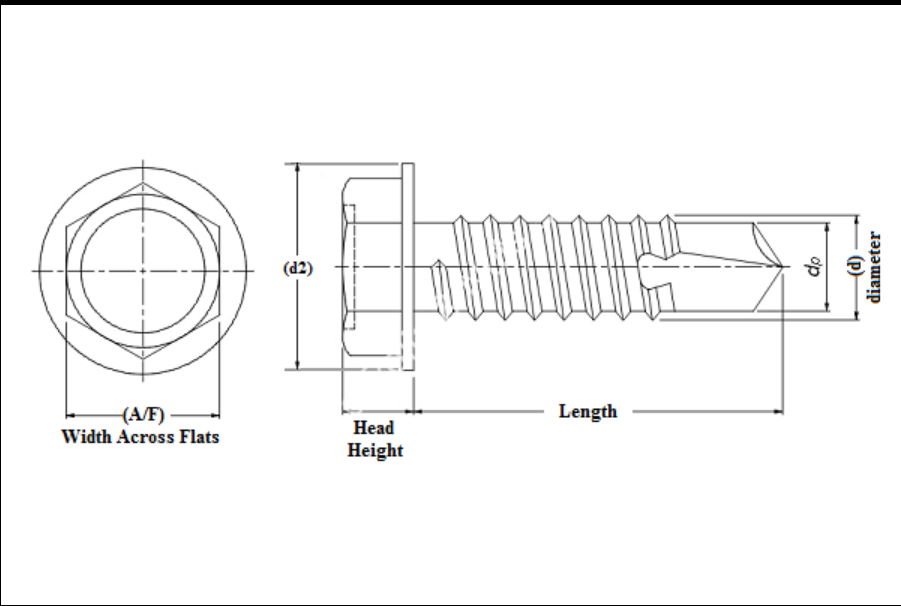

Pan head self-drilling screws are a type of fastener that combines a pan-shaped head with a self-drilling tip. This design allows the screws to penetrate different materials without the need for a pre-drilled hole, significantly speeding up the installation process. They are primarily made from stainless steel or carbon steel, providing excellent durability and corrosion resistance.

The self-drilling feature makes these screws particularly valuable in situations where quick and efficient assembly is necessary, thereby reducing labor costs and installation time. Additionally, their pan head design offers a larger bearing surface, making them ideal for securing materials where a flush finish is desired.

Applications Across Various Industries

These screws find applications across multiple sectors, including construction, automotive, electronics, and furniture manufacturing. In the construction industry, they are widely used for securing metal roofing, wall panels, and structural components. Their ability to drill into various substrates, including wood, metal, and plastic, makes them a versatile solution for both interior and exterior applications.

In the automotive sector, pan head self-drilling screws are commonly used in assembly lines to fasten components quickly and effectively

. Additionally, the electronics industry benefits from their use in securing housings and components where precision and reliability are crucial.Furthermore, furniture manufacturers also utilize these screws for assembling pieces that require quick and sturdy connections. The versatility and reliability of pan head self-drilling screws have made them a preferred choice among manufacturers and contractors alike.

supply pan head self drilling screw exporters exporter

The Global Export Market

As the demand for pan head self-drilling screws continues to grow, so too does the landscape of exporters around the globe. Countries with robust manufacturing capabilities, such as China, Germany, and the United States, have emerged as key players in the export market. These nations produce a wide variety of screws, often catering to the specific requirements of different industries.

China, in particular, has positioned itself as a dominant force in the manufacturing and exporting of fasteners, including pan head self-drilling screws. The country’s vast resources, coupled with advanced manufacturing techniques, allow it to produce high-quality screws at competitive prices. As a result, many countries rely on Chinese exporters to meet their fastening needs.

In Europe, countries like Germany and Italy are known for their emphasis on quality and precision. European manufacturers typically produce high-performance self-drilling screws that meet stringent quality standards. This focus on quality often attracts buyers looking for reliable fastening solutions for critical applications.

Navigating Challenges in the Exporting Landscape

Despite the robust demand, exporters of pan head self-drilling screws face several challenges, including fluctuating raw material prices, strict regulations, and increasing competition. Additionally, trade tariffs and restrictions can impact the cost-effectiveness of exporting these products to various regions.

To mitigate these challenges, exporters are increasingly investing in technological advancements to improve manufacturing efficiency. Furthermore, establishing strong relationships with suppliers and diversifying product lines can help maintain competitiveness in the global market.

Conclusion

The market for pan head self-drilling screws is poised for further growth, driven by an increase in construction activities and manufacturing demands worldwide. As exporters adapt to the changing landscape, their ability to provide high-quality fasteners that meet a range of applications will be crucial. By continuing to innovate and respond to market needs, the export industry for pan head self-drilling screws will remain a significant player in the global fastening solutions market. As such, stakeholders within this industry are encouraged to stay informed about trends and practices that shape the future of exports in this promising sector.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024