Exporter of Self Tapping Screw Dimensions for No 10 Size in Various Specifications

Understanding the Dimensions and Export Market of No. 10 Self-Tapping Screws

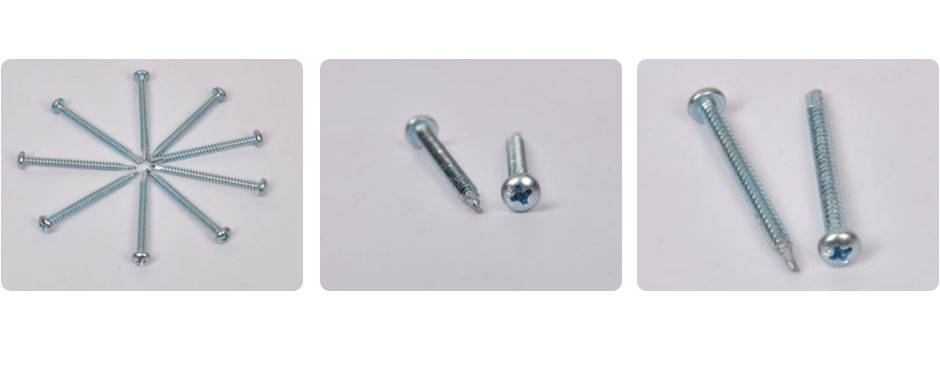

Self-tapping screws are essential components in various industries, serving crucial roles in metal and wood fastening applications. Among the various sizes available, the No. 10 self-tapping screw stands out due to its versatility and strength. In this article, we will delve into the specifications, dimensions, and export market of No. 10 self-tapping screws.

Dimensions of No. 10 Self-Tapping Screws

The designation No. 10 refers to the size of the screw, with its diameter being approximately 0.19 inches (4.8 mm). These screws are designed to be lightweight yet robust, making them suitable for a variety of applications from woodworking to roofing. The length of No. 10 self-tapping screws can vary, typically ranging from 1 inch to 3 inches (25 mm to 76 mm), enabling their use in different material thicknesses and construction requirements.

Self-tapping screws are characterized by their thread design. The threads are designed to cut into the material without requiring a pre-drilled hole, allowing for quicker and more efficient assembly. This feature is particularly advantageous in scenarios where time is of the essence or where access to tools is limited. The No. 10 screw often possesses a sharp point, facilitating easier penetration into various substrates such as plastic, wood, and softer metals.

Material and Coating

The material composition of No. 10 self-tapping screws typically includes carbon steel, stainless steel, or alloy steel, offering varying levels of strength and corrosion resistance. Coatings such as zinc, black oxide, or epoxy are often applied to enhance durability and reduce oxidation, which is particularly important for exterior applications.

Global Export Market

no 10 self tapping screw dimensions exporter

The global market for self-tapping screws, particularly the No. 10 variety, has seen significant growth over the years. With industries such as construction, automotive, and manufacturing increasingly relying on these fasteners, there is a heightened demand for quality products. Countries with substantial manufacturing capabilities, such as China, the United States, and Germany, dominate the export market.

Exporters typically adhere to international standards, ensuring that their products meet the required specifications for various applications. Quality control processes, including tensile testing and corrosion resistance testing, are essential to maintain the integrity of No. 10 self-tapping screws in the competitive global market.

Trends in the Export Market

As industries evolve, there has been a noticeable shift towards sustainability and eco-friendly practices. Many exporters are now focusing on producing screws made from recycled materials or utilizing processes that reduce environmental impact. Additionally, the rise of e-commerce has facilitated international trade, making it easier for small manufacturers and suppliers to enter the market.

Furthermore, technological advancements in manufacturing have led to innovations in screw design and functionality, catering to specific industry needs and enhancing the performance of No. 10 self-tapping screws. Automation and precision engineering have allowed for improved consistency and reduced production costs, benefiting both producers and consumers alike.

Conclusion

No. 10 self-tapping screws are vital components across various industries, characterized by their specific dimensions, versatile applications, and strong market demand. The increasing emphasis on quality and sustainability in the export market underscores the need for manufacturers to innovate and adapt. As the global economy continues to grow, the role of self-tapping screws will only become more significant, making them an essential part of modern construction and manufacturing practices. Understanding the characteristics and export trends of No. 10 self-tapping screws can help businesses navigate this crucial aspect of their supply chain effectively.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024