Comprehensive Guide to Self-Tapping Screw Applications and Related Pricing Information for Various Industries

Understanding Self-Tapping Screw Applications and Pricing

Self-tapping screws are essential fasteners widely used in various industries due to their unique ability to create their own threads as they are driven into a material. This versatility makes them particularly valuable in construction, manufacturing, and DIY projects. In this article, we will explore the applications of self-tapping screws and give an overview of their pricing, helping you make informed decisions in your projects.

Applications of Self-Tapping Screws

1. Construction In the construction industry, self-tapping screws are commonly used to fasten materials such as metal, wood, and plastic. They are ideal for connecting drywall to metal studs, fastening subflooring, and securing roofing materials. Their ability to create strong, permanent threads in various substrates makes them a go-to choice for contractors.

2. Automotive Industry Self-tapping screws are prevalent in automotive assembly due to their efficiency and reliability. They fasten components like panels, interior fixtures, and under-the-hood parts, contributing to vehicle stability and assembly speed. Their corrosion-resistant coatings also ensure durability in harsh environments.

3. Electronics In electronics manufacturing, self-tapping screws provide a reliable solution for fastening circuit boards and securing casings. These screws are specifically designed to minimize the risk of damage to delicate electronic components while ensuring a robust hold.

4. Furniture Assembly Many flat-pack furniture pieces utilize self-tapping screws for easy assembly. These screws allow consumers to quickly assemble and disassemble items like shelves, tables, and chairs without the need for specialized tools, enhancing user convenience.

5. Home Improvement Projects DIY enthusiasts often choose self-tapping screws for various home improvement tasks. Whether repairing fences, installing cabinets, or building decks, these screws simplify fastening and enhance the strength of the finished projects.

self tapping screw applications pricelist

Pricing of Self-Tapping Screws

The pricing of self-tapping screws varies depending on several factors, including material, size, coating, and quantity. On average, prices can range from a few cents for basic screws to several dollars for specialized and coated varieties.

1. Material Self-tapping screws are made from various materials, with steel being the most common choice. Stainless steel screws, known for their corrosion resistance, tend to be more expensive than standard steel screws. Additionally, screws made from other materials, such as brass or plastic, may fall within different price ranges based on their unique properties.

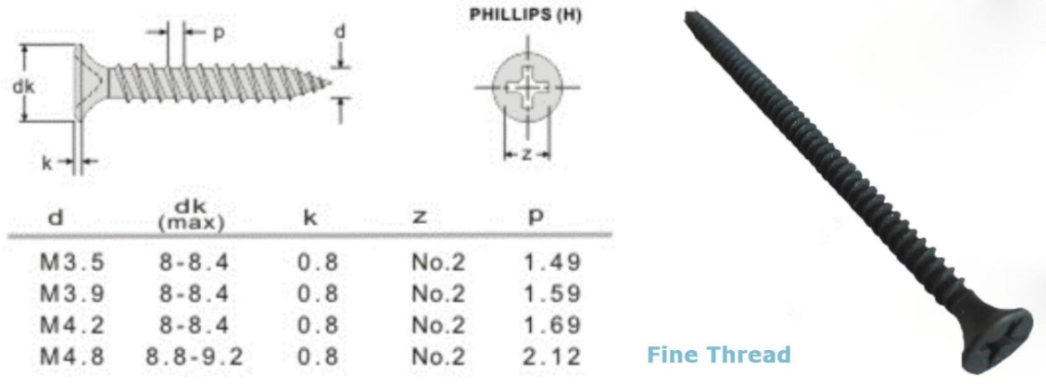

2. Size and Type The size of the screw, including its diameter and length, also influences its price. Larger and thicker screws often cost more due to the increased material used. There are also specialized types of self-tapping screws, such as those designed for specific applications (e.g., tapping for thin sheet metal) that can carry a premium.

3. Coatings Many self-tapping screws come with coatings, such as zinc plating or black oxide, which provide additional protection against corrosion. These additional treatments can increase the cost, but they often offer greater longevity in outdoor or high-moisture applications.

4. Quantity Purchased Buying in bulk typically lowers the price per unit. Many suppliers and manufacturers provide discounts for larger orders, making it cost-effective for contractors or businesses to stock up on essential fasteners.

Conclusion

Self-tapping screws play a crucial role across various industries, thanks to their ease of use and effectiveness. Understanding the applications and pricing of these fasteners can help you choose the right products for your specific needs. Whether you're a professional contractor or a DIY enthusiast, selecting the appropriate self-tapping screws can significantly impact the quality and durability of your projects.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024