Jan . 17, 2025 02:40

Back to list

5/8 drywall screw length

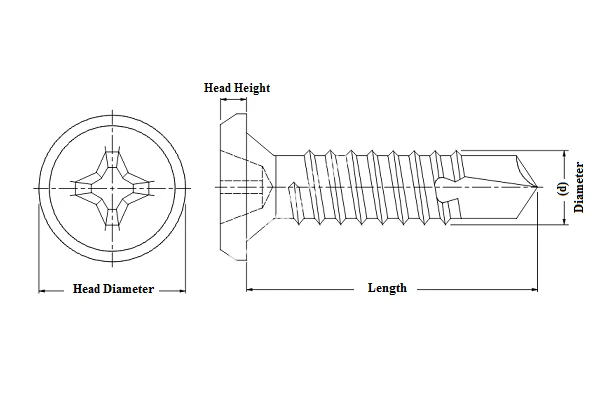

Understanding the importance of selecting the right drywall screw size can significantly impact the quality and durability of your construction projects. Whether you're a seasoned contractor or a DIY enthusiast, knowledge of drywall screw sizing is essential to ensure that your installations are secure and professional-looking.

Professionalism in drywall installation extends beyond merely choosing the correct screw size; understanding the environment where drywall is being installed is equally crucial. High-humidity areas, like kitchens and bathrooms, might benefit from corrosion-resistant screws such as zinc-coated or stainless steel to prevent rust and degradation over time. Another vital consideration is in the niche of soundproofing where specialty screws might be used. In these cases, selecting screws designed to work with sound-dampening drywall can dramatically enhance the acoustic properties of a room, creating a quieter and more serene living or working environment. Finally, effective drywall fastening relies not solely on the right screw but equally on proper installation techniques. To avoid overdriving screws, which can lead to weakened holds, utilize an adjustable screw gun or screwdriver with a clutch. In conclusion, while selecting the correct drywall screw size might seem a small component of a larger construction task, it is pivotal to building quality and secure structures. By carefully considering drywall thickness, stud type, and environmental factors, one can make informed choices that enhance the longevity and appearance of drywall installations. This thoughtful consideration and expert application grant not just credibility but also professional reliability and trustworthiness to any construction endeavor.

Professionalism in drywall installation extends beyond merely choosing the correct screw size; understanding the environment where drywall is being installed is equally crucial. High-humidity areas, like kitchens and bathrooms, might benefit from corrosion-resistant screws such as zinc-coated or stainless steel to prevent rust and degradation over time. Another vital consideration is in the niche of soundproofing where specialty screws might be used. In these cases, selecting screws designed to work with sound-dampening drywall can dramatically enhance the acoustic properties of a room, creating a quieter and more serene living or working environment. Finally, effective drywall fastening relies not solely on the right screw but equally on proper installation techniques. To avoid overdriving screws, which can lead to weakened holds, utilize an adjustable screw gun or screwdriver with a clutch. In conclusion, while selecting the correct drywall screw size might seem a small component of a larger construction task, it is pivotal to building quality and secure structures. By carefully considering drywall thickness, stud type, and environmental factors, one can make informed choices that enhance the longevity and appearance of drywall installations. This thoughtful consideration and expert application grant not just credibility but also professional reliability and trustworthiness to any construction endeavor.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News