Jan . 17, 2025 03:02

Back to list

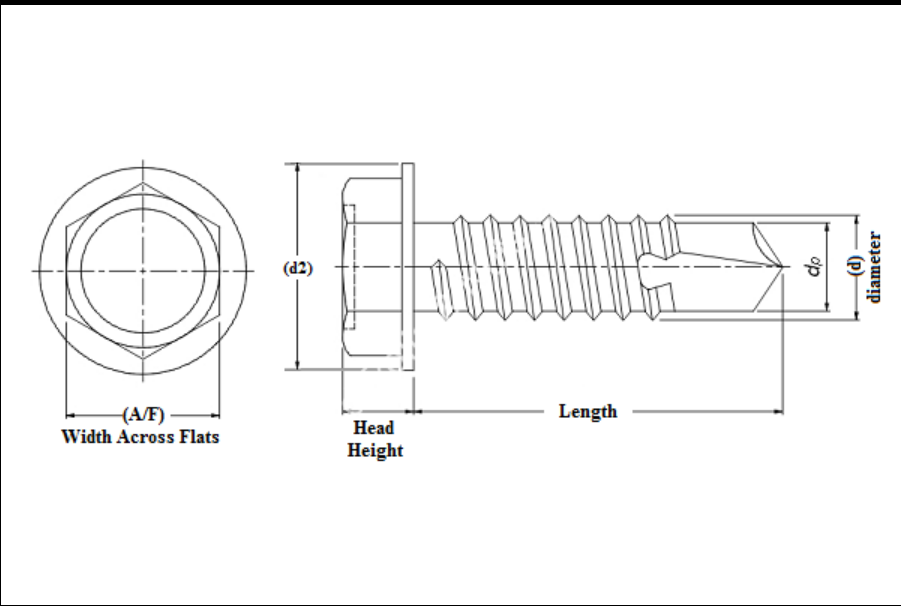

csk head self tapping screw

If you’ve ever embarked on a DIY project or been involved in construction or manufacturing, you’re probably familiar with the versatility and utility of self-tapping screws. These essential components have become a staple in both professional and DIY toolkits due to their unique ability to form internal threads in materials such as metal, plastic, or wood as they are driven in. Understanding the art and science behind these screws can significantly enhance your project outcomes, optimizing both efficiency and durability.

Authoritativeness is key when discussing why self-tapping screws are integral to various industries. According to manufacturing standards and guidelines, self-tapping screws offer a cost-effective and efficient solution for fabricating complex assemblies. In industries such as aerospace, electronics, and furniture manufacturing, reliable fastening solutions like these screws are paramount. By eliminating the need for additional components and facilitating quick adaptations during assembly, they help keep production lines fast and cost-effective. Trustworthiness of self-tapping screws is built on their consistent performance across industries. With rigorous testing to adhere to quality and safety standards, leading manufacturers invest in material sciences and engineering to ensure their products can withstand stress, vibration, and environmental factors. For consumers, this translates into confidence that the product will perform as intended. Whether constructing a simple shelving unit or working on a complex assembly line, users rely on standardized self-tapping screws to complete their tasks with guaranteed results. The practical advantages inherent in using 8 self-tapping screws come not only from their build and durability but also in the flexibility they offer across countless applications. When selecting screws for a project, considering factors such as tensile strength, thread type, and material compatibility can ensure success and longevity. Storing them properly and using the correct tools for installation will further enhance their effectiveness. In conclusion, 8 self-tapping screws illustrate the intersection of simplicity and innovation in fastening technology. By blending experience, expertise, authoritativeness, and trustworthiness, these screws provide a dependable solution for multiple applications. They offer streamlined solutions for fabricators, engineers, and DIY enthusiasts alike, cementing their role as a cornerstone in the realm of assembly and construction. When chosen correctly, these screws not only meet but exceed project expectations, paving the way for advancements in assembly technologies and applications.

Authoritativeness is key when discussing why self-tapping screws are integral to various industries. According to manufacturing standards and guidelines, self-tapping screws offer a cost-effective and efficient solution for fabricating complex assemblies. In industries such as aerospace, electronics, and furniture manufacturing, reliable fastening solutions like these screws are paramount. By eliminating the need for additional components and facilitating quick adaptations during assembly, they help keep production lines fast and cost-effective. Trustworthiness of self-tapping screws is built on their consistent performance across industries. With rigorous testing to adhere to quality and safety standards, leading manufacturers invest in material sciences and engineering to ensure their products can withstand stress, vibration, and environmental factors. For consumers, this translates into confidence that the product will perform as intended. Whether constructing a simple shelving unit or working on a complex assembly line, users rely on standardized self-tapping screws to complete their tasks with guaranteed results. The practical advantages inherent in using 8 self-tapping screws come not only from their build and durability but also in the flexibility they offer across countless applications. When selecting screws for a project, considering factors such as tensile strength, thread type, and material compatibility can ensure success and longevity. Storing them properly and using the correct tools for installation will further enhance their effectiveness. In conclusion, 8 self-tapping screws illustrate the intersection of simplicity and innovation in fastening technology. By blending experience, expertise, authoritativeness, and trustworthiness, these screws provide a dependable solution for multiple applications. They offer streamlined solutions for fabricators, engineers, and DIY enthusiasts alike, cementing their role as a cornerstone in the realm of assembly and construction. When chosen correctly, these screws not only meet but exceed project expectations, paving the way for advancements in assembly technologies and applications.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News