Jan . 17, 2025 03:26

Back to list

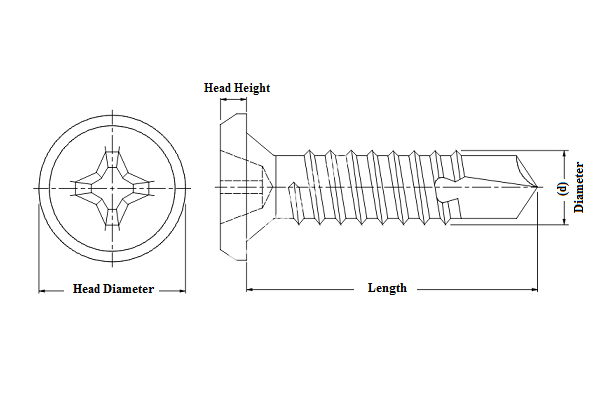

csk head self tapping screw

Self-tapping wood screws have transformed the realms of carpentry and woodworking, offering not just convenience but also a remarkable enhancement in build quality and structural integrity. For anyone passionate about or professionally involved in woodworking, understanding the intricacies of these screws is crucial to harness their full potential.

The reliability of self-tapping wood screws is built on the trust manufacturers have accumulated over decades through rigorous testing and engineering advancements. For instance, reputable brands engineer their screws with hardened steel, which undergoes treatments to withstand torsional stress and prevent stripping. This consistency in quality assures the end-user of the product's performance under varying conditions. Real-world experiences of both hobbyists and professionals using self-tapping wood screws further reinforce their effectiveness. Many attest to the significant time savings and reduced labor intensity in projects ranging from building wooden models to constructing complex architectural elements. The flexibility of these screws also means they can be used in repairs without the need for specialized tools, enhancing their usability in everyday applications. Moreover, the advent of self-tapping screws has prompted a reevaluation of traditional fastening methods. In the past, woodworking relied heavily on nails and glue, which, while effective, lacked the mechanical hold provided by screws. Modern wood joints that incorporate self-tapping screws benefit from enhanced strength and durability, able to withstand dynamic loads and mechanical stresses far better than older methods. While self-tapping wood screws continue to evolve, incorporating new materials and designs, their core advantage remains their self-sufficiency in application. As the industry pushes towards eco-friendly and sustainable construction, these screws' efficient use of materials makes them a favored choice, minimizing wastage associated with pilot drilling and fixation failures. In conclusion, self-tapping wood screws represent a perfect blend of engineering ingenuity and practical application, holding their own in both seasoned professionals' workshops and DIY enthusiasts' toolkits. By offering unmatched ease of use, structural reliability, and versatility, they have solidified their place as an essential component in woodworking projects worldwide. Embracing the full potential of these screws not only elevates craftsmanship but also inspires confidence in every project undertaken.

The reliability of self-tapping wood screws is built on the trust manufacturers have accumulated over decades through rigorous testing and engineering advancements. For instance, reputable brands engineer their screws with hardened steel, which undergoes treatments to withstand torsional stress and prevent stripping. This consistency in quality assures the end-user of the product's performance under varying conditions. Real-world experiences of both hobbyists and professionals using self-tapping wood screws further reinforce their effectiveness. Many attest to the significant time savings and reduced labor intensity in projects ranging from building wooden models to constructing complex architectural elements. The flexibility of these screws also means they can be used in repairs without the need for specialized tools, enhancing their usability in everyday applications. Moreover, the advent of self-tapping screws has prompted a reevaluation of traditional fastening methods. In the past, woodworking relied heavily on nails and glue, which, while effective, lacked the mechanical hold provided by screws. Modern wood joints that incorporate self-tapping screws benefit from enhanced strength and durability, able to withstand dynamic loads and mechanical stresses far better than older methods. While self-tapping wood screws continue to evolve, incorporating new materials and designs, their core advantage remains their self-sufficiency in application. As the industry pushes towards eco-friendly and sustainable construction, these screws' efficient use of materials makes them a favored choice, minimizing wastage associated with pilot drilling and fixation failures. In conclusion, self-tapping wood screws represent a perfect blend of engineering ingenuity and practical application, holding their own in both seasoned professionals' workshops and DIY enthusiasts' toolkits. By offering unmatched ease of use, structural reliability, and versatility, they have solidified their place as an essential component in woodworking projects worldwide. Embracing the full potential of these screws not only elevates craftsmanship but also inspires confidence in every project undertaken.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News