Comprehensive Guide to Self-Tapping Screw Dimensions and Applications for Various Projects

Understanding Self-Tapping Screws A Comprehensive Guide

Self-tapping screws are a vital component in various applications, ranging from construction and manufacturing to DIY projects at home. Unlike traditional screws that require a pre-drilled hole, self-tapping screws can cut into the material they are being driven into, creating their own hole. This unique characteristic offers numerous benefits that make them indispensable in many scenarios.

The Mechanics of Self-Tapping Screws

Self-tapping screws come equipped with sharp threads and sometimes a drill-shaped point. As they are driven into a material, the threads engage with the substrate, creating a secure hold without the need for additional hardware or pre-drilling. There are primarily two types of self-tapping screws those designed for metal and those intended for wood or plastic. Metal self-tapping screws typically have a finer thread and a pointed tip that allows for easier penetration, while wood screws are designed with wider threads for greater grip in softer materials.

Advantages of Using Self-Tapping Screws

1. Time Efficiency One of the most significant benefits of self-tapping screws is the time saved during installation. They eliminate the step of pre-drilling, allowing for faster assembly in both professional and personal projects. This can be particularly advantageous in large-scale constructions where time is of the essence.

2. Cost-Effectiveness By reducing the need for additional drilling tools and processes, self-tapping screws can also lower overall project costs. Fewer tools mean less investment upfront and simpler logistics during the construction phase.

3. Less Risk of Damage Since self-tapping screws create their own holes, there is less risk of splitting or damaging the material. This feature is especially valuable when working with softer woods or brittle materials.

4. Strong and Reliable When properly installed, self-tapping screws provide a robust and secure fastening solution. Their ability to form a tight bond with the material makes them suitable for structural applications, ensuring longevity and durability.

self tapping screw chart service

Choosing the Right Self-Tapping Screw

When selecting a self-tapping screw, it’s essential to consider the material you are working with. For instance, if you are fastening metal components, a self-tapping screw specifically designed for metal is ideal. These screws often feature a sharper point and finer threads to facilitate easier penetration into tougher materials.

Additionally, consider the size and length of the screw based on the thickness of the materials you are fastening. A screw that is too short may not provide enough grip, while one that is too long can protrude excessively, potentially causing safety hazards.

Self-Tapping Screw Charts and Services

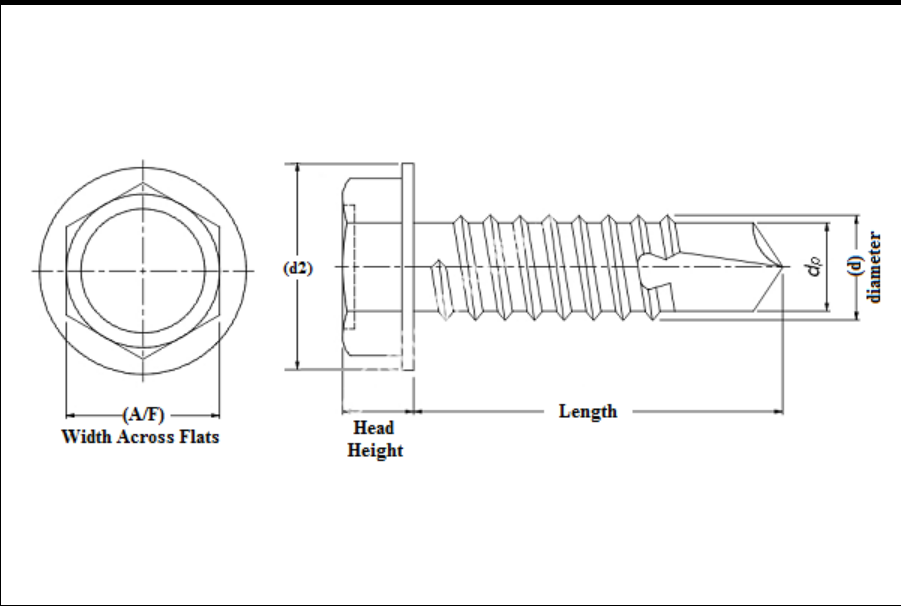

For professionals and DIY enthusiasts alike, consulting self-tapping screw charts can be incredibly beneficial. These charts provide detailed specifications, including dimensions, threading types, head styles, and suitable materials. Access to this information can simplify decision-making and ensure that you choose the appropriate screw for your project.

Moreover, numerous services and suppliers offer customized self-tapping screw solutions. Whether you require specific dimensions or unique materials, getting in touch with a service provider can help meet your needs and optimize your projects.

Conclusion

Self-tapping screws play an integral role in modern construction and manufacturing. Their ease of use, efficiency, and reliability make them a preferred option for many applications. By understanding the mechanics and benefits of self-tapping screws, as well as consulting detailed charts and services, you can enhance your construction projects and ensure successful outcomes. Whether you’re a seasoned professional or a novice DIYer, the right self-tapping screws can make all the difference in achieving a secure and lasting hold.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024