Exploring the Benefits and Uses of ODM12 Flat Washers in Various Applications

Understanding ODM 12 Flat Washers A Key Component in Mechanical Applications

In the realm of mechanical engineering and construction, precision and reliability are paramount. One of the unsung heroes that contribute significantly to these qualities is the flat washer, specifically the ODM 12 flat washer. While often overlooked, the importance of flat washers should not be underestimated, as they play a critical role in various applications by distributing load, providing insulation, and preventing loosening of fasteners.

What is an ODM 12 Flat Washer?

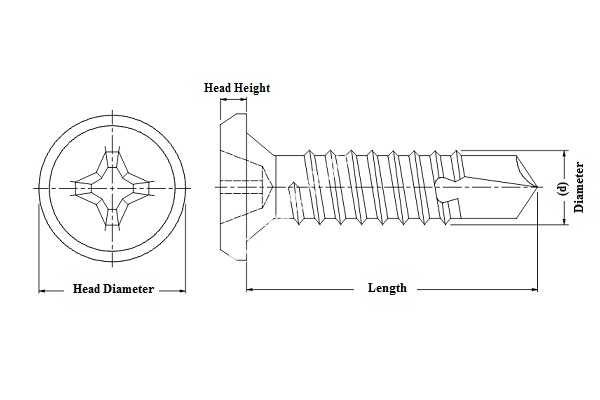

An ODM 12 flat washer is a disc-shaped piece of hardware that is used in conjunction with screws, bolts, and nuts. The term ODM refers to the standards set by the Original Design Manufacturer, ensuring that the washer conforms to specific dimensional and performance metrics. The 12 designation indicates the size of the washer, which is compatible with 12 screws and bolts. Typically made from materials such as stainless steel, carbon steel, or nylon, flat washers come in various diameters and thicknesses to suit different applications.

The Functionality of Flat Washers

The primary function of flat washers is to distribute the load of a fastener over a larger surface area. When a bolt or screw is tightened, it can create a considerable amount of pressure against the material it is fastening. Without a washer, this pressure can lead to deformation of the surface material, which may result in failure of the joint over time. By using an ODM 12 flat washer, the load is spread more evenly, reducing the risk of damage and ensuring the longevity of the joint.

Additionally, flat washers serve as a barrier between the fastener and the substrate. This isolation helps prevent galvanic corrosion, which occurs when two different metals are in contact and create an electrical current that leads to deterioration. Using a washer made from non-corrosive materials can help mitigate this issue, particularly in outdoor or marine environments where exposure to moisture and salt can be detrimental.

odm #12 flat washer

Flat washers can also play a vital role in providing insulation. In electronic or electrical applications, the use of a non-conductive washer can prevent short circuits by ensuring that electrical connections do not inadvertently touch conductive materials.

Installation Best Practices

When installing ODM 12 flat washers, there are a few best practices to keep in mind to ensure optimal performance. First, always choose a washer that matches the specifications of the fastener being used. An undersized washer will not provide adequate load distribution, while an oversized washer may not fit well in the intended application.

Secondly, it is essential to clean the surfaces where the washer will be installed. Dirt, debris, and other contaminants can compromise the integrity of the bolt joint and lead to premature failure. Lastly, proper torque application when tightening bolts is critical. Over-tightening can strip threads and deform the washer, while under-tightening can lead to loosening over time.

Conclusion

In summary, the ODM 12 flat washer is a small but vital component in various mechanical and construction applications. By providing load distribution, preventing corrosion, and offering electrical insulation, these washers enhance the reliability and durability of fastened joints. Whether you are a seasoned engineer or a DIY enthusiast, understanding the importance of flat washers can significantly improve the outcomes of your projects. Always consider the specifications and quality of the washers you use, as they are fundamental to achieving long-lasting and successful results.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024