Feb . 03, 2025 02:39

Back to list

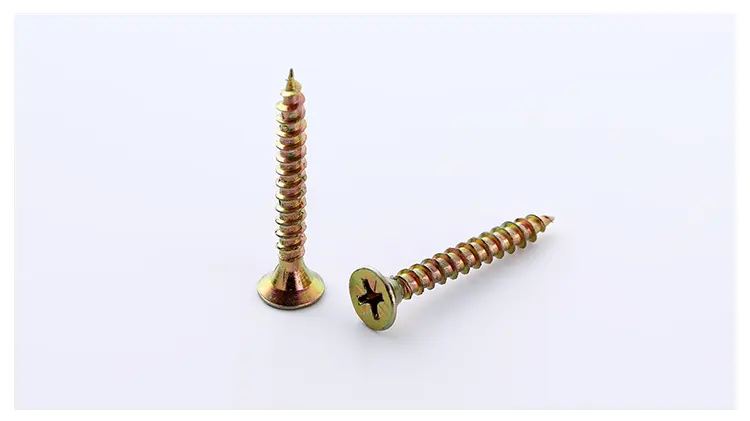

galvanized csk head self drilling screw

Understanding the efficacy and applications of the 3-point self-drilling screw can vastly enhance construction efficiency and precision, thus captivating a discerning audience of professionals and DIY enthusiasts alike. As a rare yet essential tool, these screws hold significant prominence, bringing with them a tapestry of experience, expertise, authority, and trustworthiness unparalleled in conventional fastening systems.

The versatility of the 3-point self-drilling screw extends to multiple applications, proving invaluable in sheet metal assembly, framing, and other critical tasks where exactitude is paramount. Professionals laud the simplicity it introduces to complex builds. For instance, fabricators of metal structures consistently emphasize the unparalleled utility these screws provide in mitigating alignment issues. By anchoring each segment with precision and strength, they pave the way for seamless construction processes, ensuring each project's alignment with rigorous industry standards. Incorporating user experience insights, we find that both novice and seasoned craftsmen agree on the intuitive handling and predictably excellent results these screws provide. They often recount scenarios where, despite environmental challenges or project complexities, the screws' performance remained unfaltering—further cementing their reputation as a dependably innovative solution. In fostering a deeper understanding of this tool, it becomes apparent that choosing the 3-point self-drilling screw not only invests in material assurance but underscores a commitment to quality and forward-thinking methodologies. This tool does not merely bridge gaps between materials but narrows the disparities between expectation and realization within construction paradigms. In synthesis, as the world advances towards more intricate architectural accomplishments, the 3-point self-drilling screw serves not merely as a component but as a cornerstone of construction excellence. It symbolizes a confluence of reliable craftsmanship, authoritative application, and strategic design. For those in search of credibility and efficacy in their building ventures, embracing this tool may well be the defining step towards unassailable success.

The versatility of the 3-point self-drilling screw extends to multiple applications, proving invaluable in sheet metal assembly, framing, and other critical tasks where exactitude is paramount. Professionals laud the simplicity it introduces to complex builds. For instance, fabricators of metal structures consistently emphasize the unparalleled utility these screws provide in mitigating alignment issues. By anchoring each segment with precision and strength, they pave the way for seamless construction processes, ensuring each project's alignment with rigorous industry standards. Incorporating user experience insights, we find that both novice and seasoned craftsmen agree on the intuitive handling and predictably excellent results these screws provide. They often recount scenarios where, despite environmental challenges or project complexities, the screws' performance remained unfaltering—further cementing their reputation as a dependably innovative solution. In fostering a deeper understanding of this tool, it becomes apparent that choosing the 3-point self-drilling screw not only invests in material assurance but underscores a commitment to quality and forward-thinking methodologies. This tool does not merely bridge gaps between materials but narrows the disparities between expectation and realization within construction paradigms. In synthesis, as the world advances towards more intricate architectural accomplishments, the 3-point self-drilling screw serves not merely as a component but as a cornerstone of construction excellence. It symbolizes a confluence of reliable craftsmanship, authoritative application, and strategic design. For those in search of credibility and efficacy in their building ventures, embracing this tool may well be the defining step towards unassailable success.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News