Feb . 03, 2025 02:57

Back to list

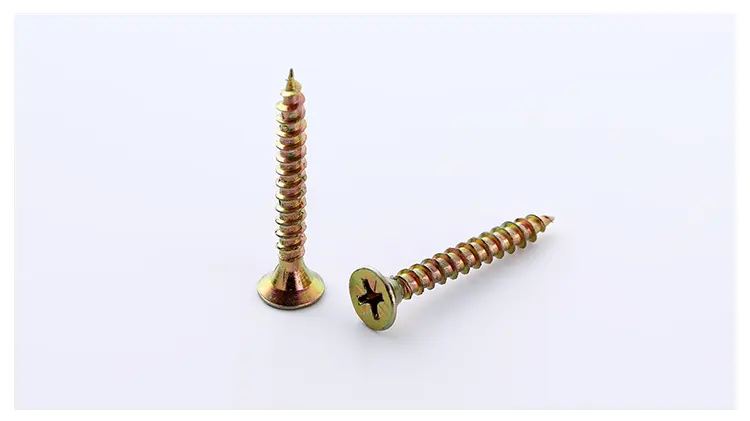

galvanized csk head self drilling screw

410 stainless steel self-drilling screws have garnered significant attention in various industries due to their distinctive properties and unparalleled functionality. As industrial demands grow more specific and the need for durable materials becomes paramount, understanding the potential of these screws can give businesses a competitive edge.

Trustworthiness is another core component when considering materials for critical projects. The credibility of 410 stainless steel screws is reinforced by rigorous quality control standards and certifications from industry-leading organizations such as ISO and ASTM. Manufacturers provide detailed specification sheets that outline the performance parameters of these screws, ensuring that their application will meet the precise needs of each project. Furthermore, testimonials from well-regarded contractors and testimonials from companies that have utilized these screws provide real-world assurance of their dependability. For businesses and professionals seeking a product that aligns with the highest standards of durability, efficiency, and dependability, the 410 stainless steel self-drilling screw presents itself as a superb choice. Its versatile nature makes it applicable in a vast array of settings, from constructing skyscrapers to assembling household metal appliances. It's a product that speaks to professional integrity and commitment to quality, reducing the likelihood of repairs and replacements. As the industrial landscape continues to advance, embracing materials with proven records and certified strengths is crucial. The 410 stainless steel self-drilling screw is not just another tool in the toolbox, but a trusted partner that ensures longevity and performance in numerous applications. Whether emphasizing cost efficiency or environmental resilience, these screws are the embodiment of modern engineering excellence.

Trustworthiness is another core component when considering materials for critical projects. The credibility of 410 stainless steel screws is reinforced by rigorous quality control standards and certifications from industry-leading organizations such as ISO and ASTM. Manufacturers provide detailed specification sheets that outline the performance parameters of these screws, ensuring that their application will meet the precise needs of each project. Furthermore, testimonials from well-regarded contractors and testimonials from companies that have utilized these screws provide real-world assurance of their dependability. For businesses and professionals seeking a product that aligns with the highest standards of durability, efficiency, and dependability, the 410 stainless steel self-drilling screw presents itself as a superb choice. Its versatile nature makes it applicable in a vast array of settings, from constructing skyscrapers to assembling household metal appliances. It's a product that speaks to professional integrity and commitment to quality, reducing the likelihood of repairs and replacements. As the industrial landscape continues to advance, embracing materials with proven records and certified strengths is crucial. The 410 stainless steel self-drilling screw is not just another tool in the toolbox, but a trusted partner that ensures longevity and performance in numerous applications. Whether emphasizing cost efficiency or environmental resilience, these screws are the embodiment of modern engineering excellence.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News