wholesale bolt spring washer

Understanding Wholesale Bolt Spring Washers A Comprehensive Guide

In the world of hardware and fastening solutions, spring washers play a crucial role in ensuring the reliability and durability of various applications. When it comes to bulk buying, particularly in wholesale transactions, understanding the nuances of bolt spring washers can save businesses time and money. This article will delve into the importance, types, and considerations associated with wholesale bolt spring washers.

What is a Bolt Spring Washer?

A bolt spring washer, often referred to as a spring lock washer, is a type of fastener that provides a flexible mechanism to maintain tension in bolted joints. These washers are designed to prevent loosening under vibration or torque. The curved shape of a spring washer allows it to exert a constant pressure against the bolt head or nut, ensuring a secure assembly. They are commonly used in various industries, including automotive, construction, and manufacturing.

Importance of Spring Washers

The significance of using spring washers cannot be overstated. One of the primary benefits is their ability to absorb shocks and vibrations. In environments where machinery operates at high speeds or where equipment is subject to continuous movement, spring washers help maintain the integrity of connections and prevent fasteners from loosening over time.

Additionally, spring washers can accommodate thermal expansion and contraction in materials, which is particularly important in applications that experience significant temperature fluctuations. This functional versatility makes them a preferred choice for engineers and manufacturers alike.

Types of Spring Washers

When considering wholesale options, it’s essential to understand the different types of bolt spring washers available

1. Internal Tooth Lock Washers These washers have teeth on the inside and grip against the bolt and the material they’re screwed to. This type is ideal for applications requiring a strong hold.

2. External Tooth Lock Washers Unlike internal tooth variants, these feature teeth on the outside, providing grip against the surface they are installed on. They are commonly used when securing larger surfaces.

wholesale bolt spring washer

3. Split Lock Washers These have a split or gap that creates tension and flexibility. When compressed, the washer exerts pressure to secure the bolt or nut in place.

4. Conical Washers These are designed to counteract the tendency of bolts to loosen from vibrations, providing a more significant resistance to movement.

5. Belleville Washers Often referred to as disc springs, Belleville washers provide exceptional flexibility and load-bearing capabilities, making them suitable for high-stress applications.

Considerations When Purchasing Wholesale Spring Washers

1. Material The choice of material significantly impacts the performance and durability of spring washers. Common materials include stainless steel, carbon steel, and plastic. Stainless steel washers are corrosion-resistant, while carbon steel provides strength and durability.

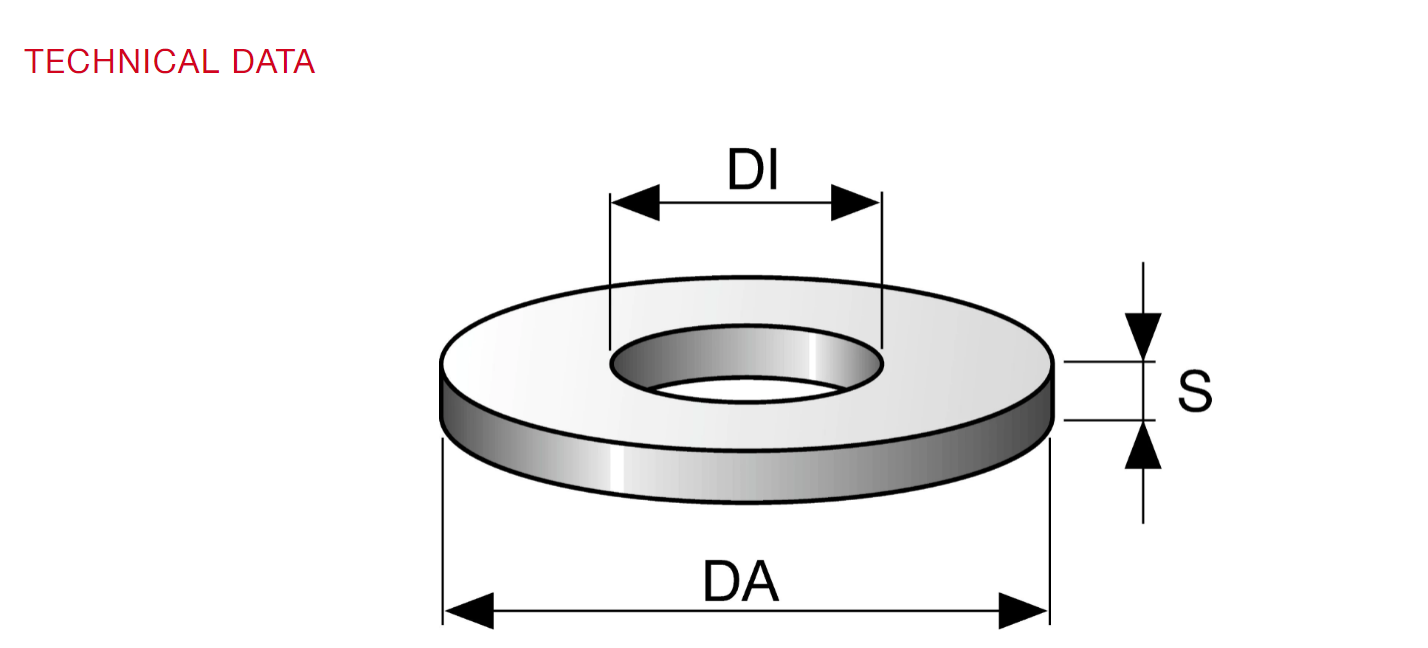

2. Size and Thickness When ordering in bulk, it’s crucial to specify the correct dimensions. Spring washers come in various sizes to fit different bolt diameters, and the thickness can directly affect the level of tension and flexibility.

3. Load Requirements Businesses must assess the load that the washers will bear. High-load applications require robust washers capable of withstanding significant force.

4. Certification and Standards Ensuring that the spring washers comply with industry standards is paramount. Look for certifications that guarantee the quality and reliability of the washers being purchased.

5. Supplier Reputation Partnering with a reputable wholesale supplier can make a significant difference in product quality and customer service. Research potential suppliers, read reviews, and consider requesting samples before placing large orders.

Conclusion

Wholesale bolt spring washers are indispensable components in various mechanical and structural applications. By understanding their function, types, and purchasing considerations, businesses can make informed decisions that enhance the reliability of their assemblies. Careful selection of materials, sizes, and suppliers can lead to significant cost savings and improved operational efficiency, making them a wise investment for any organization involved in manufacturing or machine maintenance.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024