drywall screw assortment factories

Understanding Drywall Screw Assortment Factories

In the construction and building materials industry, drywall screws play a pivotal role in ensuring the structural integrity and aesthetic appeal of interiors. Drywall screws are specialized fasteners designed to attach drywall to wooden or metal framing. They come in various sizes and types, suitable for different applications. The demand for these screws has led to the emergence of specialized factories that focus on producing drywall screw assortments. This article explores the significance of drywall screw assortment factories, their production processes, and their contribution to the construction industry.

The Importance of Drywall Screws

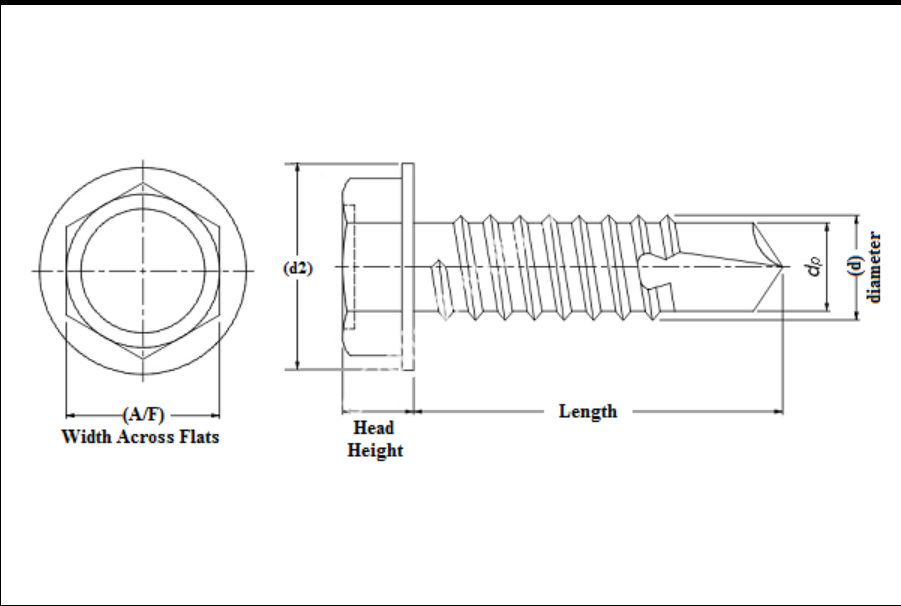

Drywall screws are characterized by their sharp tips, which allow for easy penetration into drywall and framing materials. Unlike regular screws, drywall screws have a bugle-shaped head that helps prevent tearing of the drywall paper surface when the screw is driven in. The threads are designed to provide a strong hold, reducing the risk of the screws loosening over time due to temperature fluctuations or structural settling.

These fasteners are essential in residential, commercial, and industrial applications. They are used in wall assemblies, ceilings, and partitions, contributing to both the functionality and aesthetics of a space. As the construction industry continues to evolve, the demand for high-quality drywall screws remains robust, necessitating the need for specialized manufacturing facilities.

The Role of Drywall Screw Assortment Factories

Drywall screw assortment factories specialize in producing a variety of screws tailored for different drywall applications. These factories operate with a focus on efficiency and quality control. The production of drywall screws involves several critical steps

1. Material Selection Factories begin with high-quality raw materials, often using steel or zinc-coated steel, which provides durability and resistance to rusting. High tensile strength is essential to withstand the forces exerted during installation and over time.

2. Manufacturing Process The manufacturing process typically includes cold heading, threading, and coating. Cold heading is a technique that shapes the screw head without heating the metal, ensuring that the screws retain their strength. Threading is done using precise machinery to create the necessary thread pattern for optimal grip. Coating, such as galvanization, is applied to enhance corrosion resistance.

drywall screw assortment factories

3. Quality Control Ensuring that each screw meets industry standards is crucial. Factories employ stringent quality control measures, including testing for tensile strength, corrosion resistance, and dimensional accuracy. This ensures that the screws are safe and effective for their intended use.

4. Assortment Packaging To cater to various customer needs, drywall screw assortment factories create packages that may include different lengths, thread types, and head styles. This assortment makes it convenient for contractors and DIY enthusiasts to find the right screws for their specific projects.

The Advantages of Specialized Factories

The specialization of drywall screw factories provides several advantages

- Economies of Scale By focusing on a single product line, these factories can produce screws in larger quantities, reducing costs and making their products more accessible to consumers.

- Innovation Specialized factories are more likely to invest in research and development, leading to innovations in screw design and manufacturing techniques. This can result in the production of screws that are more efficient, easier to install, and better suited to modern building materials.

- Expertise With a concentrated focus on drywall screws, these factories accumulate expertise in the field. This knowledge allows them to respond quickly to market demands and provide tailored solutions to customers.

Conclusion

Drywall screw assortment factories play a crucial role in the construction industry by providing essential fasteners that ensure the reliability and aesthetics of drywall installations. Their specialized manufacturing processes, commitment to quality, and ability to innovate greatly contribute to the efficiency of construction projects. As the construction landscape continues to evolve with new materials and techniques, the importance of these factories in delivering high-quality dry drywall screws will remain indispensable. For contractors and builders, understanding the value of drywall screw assortments is integral to ensuring the success of their projects.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024