Jan . 21, 2025 00:54

Back to list

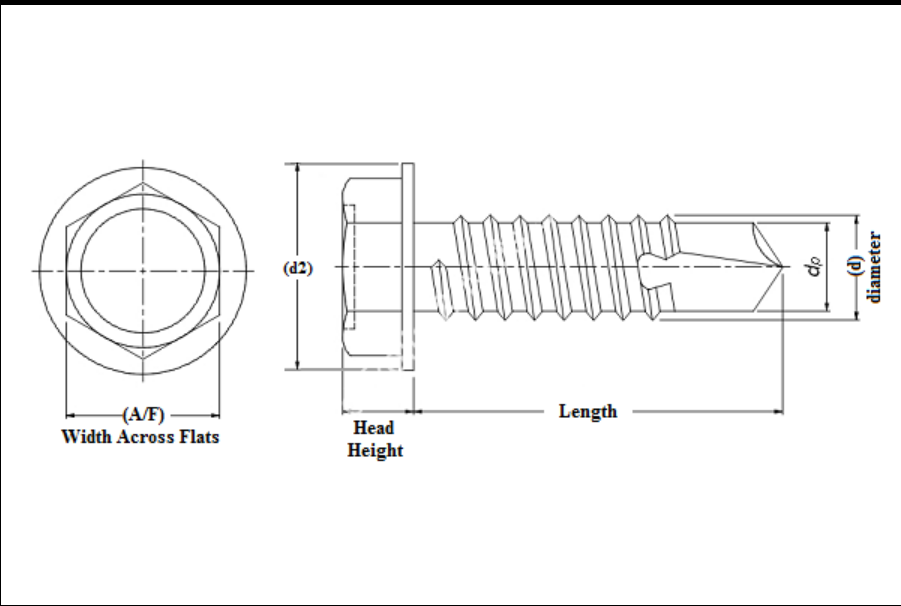

self drilling screw sizes

Selecting the correct size for self-drilling screws is crucial for ensuring the efficiency and safety of construction and DIY projects. These screws are specially designed to combine both the drill bit and the fastening element in a single piece. This feature makes them incredibly useful for tasks that require quick and precise fastening in metal and wood without the need for pre-drilling.

In addition to size and point type, the material and coating of the screw are crucial for the longevity and performance of the application. Self-drilling screws are typically made from hardened steel or stainless steel, offering resistance to corrosion and wear. Coatings such as zinc or cadmium provide additional protection against rust, making them suitable for outdoor or humid environments. Employing self-drilling screws with the wrong specification can lead to failed joints, increased labor costs, and possible safety hazards. Therefore, understanding the exact requirements of your project is paramount. Consulting manufacturer specifications and technical data sheets can offer invaluable guidance in selecting the correct screw for specific applications. Professionals and DIY enthusiasts should also consider purchasing screws from reputable suppliers who provide detailed information about the products. This ensures that you utilize high-quality screws that meet the necessary standards and certifications required for your project. In summary, selecting the correct self-drilling screw involves understanding the material and mechanical requirements of your project, as well as considering the screw’s diameter, length, point type, head style, and material characteristics. By doing so, you enhance the efficiency, safety, and durability of your work.

In addition to size and point type, the material and coating of the screw are crucial for the longevity and performance of the application. Self-drilling screws are typically made from hardened steel or stainless steel, offering resistance to corrosion and wear. Coatings such as zinc or cadmium provide additional protection against rust, making them suitable for outdoor or humid environments. Employing self-drilling screws with the wrong specification can lead to failed joints, increased labor costs, and possible safety hazards. Therefore, understanding the exact requirements of your project is paramount. Consulting manufacturer specifications and technical data sheets can offer invaluable guidance in selecting the correct screw for specific applications. Professionals and DIY enthusiasts should also consider purchasing screws from reputable suppliers who provide detailed information about the products. This ensures that you utilize high-quality screws that meet the necessary standards and certifications required for your project. In summary, selecting the correct self-drilling screw involves understanding the material and mechanical requirements of your project, as well as considering the screw’s diameter, length, point type, head style, and material characteristics. By doing so, you enhance the efficiency, safety, and durability of your work.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News