Jan . 21, 2025 01:13

Back to list

10 hex head self tapping screw

Choosing the right type of screw for a project can be an overwhelming task given the vast variety available in the market. Among these, the 10 hex head self-tapping screw stands out due to its versatile applications, exceptional design, and reliability in various DIY and construction tasks. This article aims to delve deep into the anatomy, applications, and benefits of using 10 hex head self-tapping screws, thereby boosting your understanding and ensuring your projects maintain high standards of durability and efficiency.

The expertise embedded in the manufacturing process of a 10 hex head self-tapping screw ensures conformity to rigorous industry standards. This adherence to quality is confirmed by the various certifications and audits major manufacturers undergo to guarantee their products meet and exceed consumer expectations regarding performance and safety. Incorporating the insights from specialists and experienced users alike, it's clear that the hex head configuration not only enhances performance but contributes significantly to user-friendliness. For instance, tradesmen and hobbyists appreciate the hex head’s unique ability to enable swift adjustments and repositioning mid-task without damaging the screw or the material. Testimonials from professionals who regularly employ 10 hex head self-tapping screws in their work often praise the balance they offer between strength and efficiency. Given their versatility, these screws are also a mainstay in automotive repair, where reliability is a non-negotiable requirement. Whether attaching a license plate to a vehicle or securing brackets under the hood, the assurance that these screws will hold firm under pressure is invaluable. In conclusion, the 10 hex head self-tapping screw is a testament to the synthesis of engineering precision and practical efficacy. For enthusiasts and professionals committed to high-quality outcomes, their implementation into a project signifies a step towards excellence. Selecting these screws extends beyond mere utility; it reflects a dedication to craftsmanship and an understanding of materials science that ultimately benefits the end-user through longevity and reliability. Engaging with this transformative product ensures that every task is accomplished with a level of sophistication that aligns with contemporary construction and manufacturing standards.

The expertise embedded in the manufacturing process of a 10 hex head self-tapping screw ensures conformity to rigorous industry standards. This adherence to quality is confirmed by the various certifications and audits major manufacturers undergo to guarantee their products meet and exceed consumer expectations regarding performance and safety. Incorporating the insights from specialists and experienced users alike, it's clear that the hex head configuration not only enhances performance but contributes significantly to user-friendliness. For instance, tradesmen and hobbyists appreciate the hex head’s unique ability to enable swift adjustments and repositioning mid-task without damaging the screw or the material. Testimonials from professionals who regularly employ 10 hex head self-tapping screws in their work often praise the balance they offer between strength and efficiency. Given their versatility, these screws are also a mainstay in automotive repair, where reliability is a non-negotiable requirement. Whether attaching a license plate to a vehicle or securing brackets under the hood, the assurance that these screws will hold firm under pressure is invaluable. In conclusion, the 10 hex head self-tapping screw is a testament to the synthesis of engineering precision and practical efficacy. For enthusiasts and professionals committed to high-quality outcomes, their implementation into a project signifies a step towards excellence. Selecting these screws extends beyond mere utility; it reflects a dedication to craftsmanship and an understanding of materials science that ultimately benefits the end-user through longevity and reliability. Engaging with this transformative product ensures that every task is accomplished with a level of sophistication that aligns with contemporary construction and manufacturing standards.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

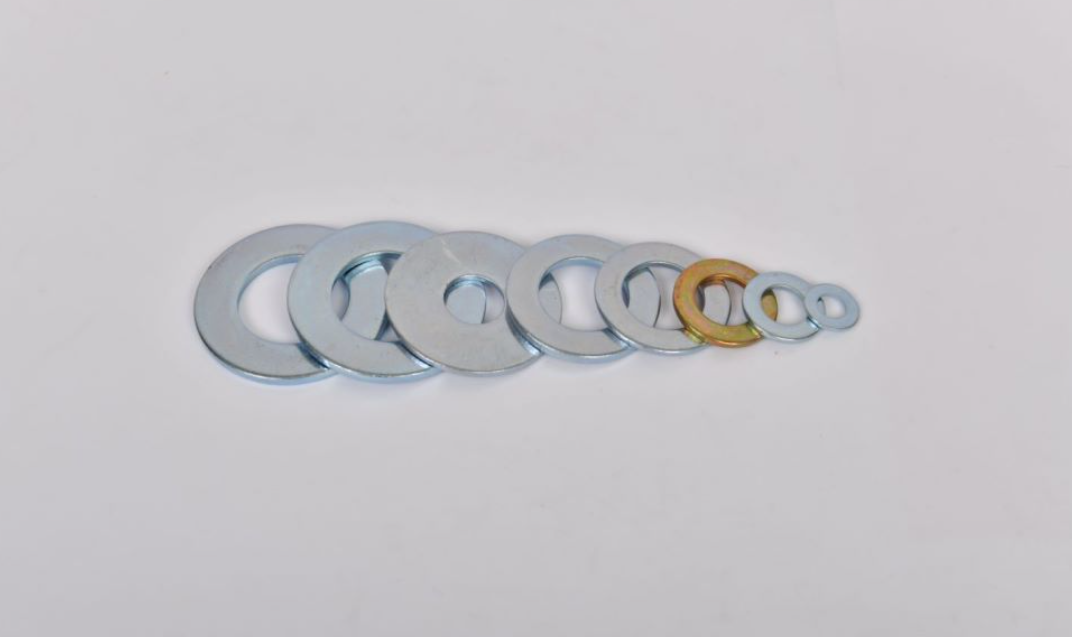

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News