Ruspert coating screw

Ruspert coating (also called ceramic coating) is a high-grade protective coating to prevent metals from corrosion in various pollutive and atmospheric conditions. The surface is usually in silver color but can come in range of colors depending on the application. Ruspert coating consists of three layers:

• The 1st layer: Metallic zinc layer

• The 2nd layer: Special chemical conversion coating layer

• The 3rd layer: Rustproof layer (Baked ceramic surface coating layer)

All DL Fastener screws with Ruspert coating can provide anti-corrosion performance of 500 hours, 1000 hours and 1500 hours neutral salt spray test.

The unique feature of Ruspert Coating is the tight joining of the baked ceramic top coating and the chemical conversion film thanks to the cross-linking effect. These three layers are bonded together with the metallic zinc layer through chemical reactions, and this unique method of combining layers results in a rigid and dense combination of the coating films.

Other benefits of Ruspert coating screw

1. Low Processing Temperatures: The highest temperature during Ruspert coating will be under 200℃. The low temperature prevents metallurgic changes from occurring in the metal substrate. It will maintain the mechanical properties of screws when processing. This is particularly important for self drilling screw, self tapping screw and chipboard screw. Because we need to to ensure the tensile strength and hardness after coating to make sure it won't effect the drilling ability.

2. Timber Preservative Resistance: The high moisture content and salt levels of treated timber will cause screws to corrode at a much faster speed. Ruspert's high resistance to high moisture and salty conditions make it suitable for use in treated timber. Using a Ruspert coating on these screws will have a long life connection than zinc plated or dacromet screws.

3. Contact Corrosion Resistance: Since the free zinc layer is protected from physical contact with other metal surfaces by a non-conductive ceramic top layer, the free zinc layer only provides galvanic protection for the metal substrate. Which means screws coated with Ruspert will not sacrifice its zinc coating to protect the fastener outside the material. This eliminates any contact corrosion problems with other metals or metal-coated materials when used under wet and dry conditions.

Which one should I choose, Ruspert, Zinc plating or Dacromet?

Product with Ruspert coatings are often used with other zinc based coatings such as zinc plating and dacromet. As with all coatings, their choice depends on the application.

Zinc plating has good adhesion, but the thin coating (-5pm) means poor corrosion resistance, and is only suitable for indoor and low corrosion environment. That is why zinc plating is not recommended for treated timber(hardwood or softwood).

Dacromet coating has good adhesion and improve corrosion resistance, but the layer is susceptible to corrosion when in contact with other metals.

Ruspert's excellent adhesion and corrosion protection make it suitable for applications requiring additional protective elements such as outdoor drilling screws, deck screws and wood screws.

- El día de la carga, el cliente visitó nuestra fábrica para inspeccionar su envío de tornillos autoperforantes.

- Nuestros clientes estaban complacidos de ver que todos nuestros productos eran de la más alta calidad con un tratamiento de superficie brillante.

- Los tornillos autoperforantes cincados están especialmente diseñados para resistir la corrosión y el óxido, lo que garantiza que permanezcan seguros y estables en cualquier entorno.

- Como empresa estamos comprometidos con la calidad del producto, por eso utilizamos los mejores materiales y la última tecnología para producir nuestros tornillos autoperforantes.

- En conclusión, nuestros visitantes quedaron impresionados con la inspección de su envío y quedaron muy satisfechos con la calidad y el empaque de nuestros productos.

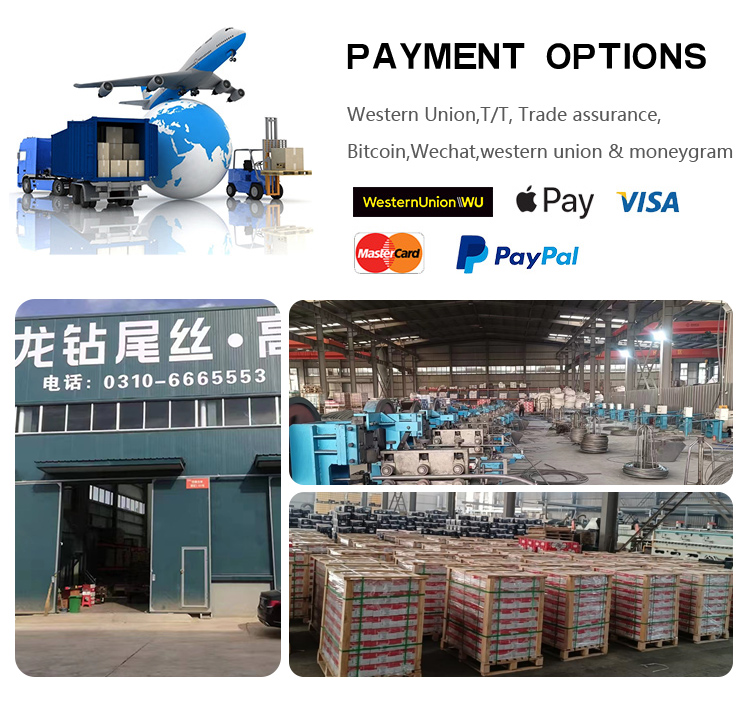

Hebei Delong Fastener Manufacturing Co., Ltd. está ubicada en el distrito de Yongnian, ciudad de Handan, provincia de Hebei, el centro de distribución de sujetadores. Está cerca de la autopista Beijing Zhuhai, el ferrocarril Beijing Guangzhou y la autopista nacional 107. Tiene un transporte conveniente y una ubicación geográfica superior.

Hebei Delong Fastener Manufacturing Co., Ltd. está ubicada en el distrito de Yongnian, ciudad de Handan, provincia de Hebei, el centro de distribución de sujetadores. Está cerca de la autopista Beijing Zhuhai, el ferrocarril Beijing Guangzhou y la autopista nacional 107. Tiene un transporte conveniente y una ubicación geográfica superior.

La empresa fue fundada en 2006. La empresa se centra en la I+D de elementos de fijación de alta gama, con una capacidad de producción anual de más de 8000 toneladas. Cuenta con equipos de producción, tecnología y equipos de tratamiento térmico de primera clase en Taiwán.

Gerente general: señor jin

TELÉFONO: 86-310-6665553

Móvil: +86 13703109255

¿Cuál es la aplicación: +8615932307696

Sitio web: www.delongfastener.com

Correo electrónico: sales@delongfastener.com