narrow flat washer company

The Role of Narrow Flat Washer Companies in Industrial Applications

In the fast-evolving landscape of manufacturing and construction, small components often play crucial roles in ensuring the functionality, safety, and longevity of larger systems. One such critical component is the narrow flat washer. Companies that specialize in the production of these washers have become essential players in various industries, from automotive to construction and beyond.

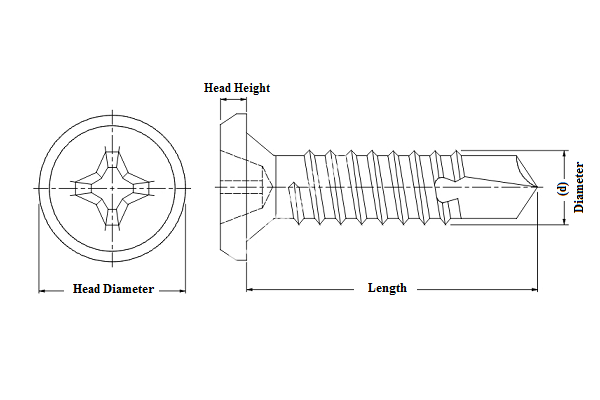

Narrow flat washers are thin, circular pieces of metal or plastic designed to distribute the load of a threaded fastener, such as a screw or bolt. Their primary function is to provide a smooth surface and prevent damage to the material being fastened. By creating a larger bearing surface, these washers help to reduce the risk of the fastener pulling through the material, thereby enhancing the overall strength and reliability of the assembly.

Importance of Material Selection

The materials used in the manufacturing of narrow flat washers significantly influence their performance and suitability for various applications. Common materials include steel, stainless steel, brass, and plastic. Each material offers different benefits; for example, stainless steel is known for its corrosion resistance, making it ideal for applications exposed to moisture and chemicals, while plastic washers might be preferred in electrical applications due to their insulating properties.

Leading narrow flat washer companies are adept at sourcing high-quality materials that meet industry standards. They often provide customization options, allowing clients to request specific sizes, thicknesses, and finishes that align with their unique requirements. This adaptability is crucial in sectors like aerospace and automotive, where stringent regulations dictate the properties and performance of every component used.

Precision Manufacturing Techniques

narrow flat washer company

To ensure that narrow flat washers meet precise specifications, companies utilize advanced manufacturing techniques. Techniques such as stamping, laser cutting, and CNC machining allow for high levels of precision and repeatability. The use of modern technology not only enhances the quality of the washers produced but also increases production efficiency, allowing companies to scale their operations to meet growing demand.

Moreover, stringent quality control processes are employed throughout the manufacturing cycle. Companies conduct regular inspections and testing, including tensile strength tests and dimensional checks, to ensure that their products comply with international standards and customer specifications. This commitment to quality helps build trust with clients and establishes a company's reputation in the industry.

Application Across Industries

The versatility of narrow flat washers means that they are used in diverse applications across various industries. In the automotive sector, they are employed in engine assembly, chassis construction, and electrical systems, contributing to the safety and performance of vehicles. In construction, these washers are critical in building structures, ensuring that bolts and screws maintain their integrity under load. Additionally, they find applications in electronics, machinery, and even household appliances, underscoring their ubiquitous nature.

Conclusion

As industries continue to evolve and embrace new technologies, the demand for high-quality components like narrow flat washers is set to grow. Companies specializing in this niche play a pivotal role in supplying reliable products that ensure the proper functioning of complex systems. By focusing on material selection, precision manufacturing, and strict quality control, these companies not only meet the needs of their clients but also contribute to the overall safety and efficiency of various industries. In an environment where every component matters, the role of narrow flat washer companies will remain indispensable for years to come.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024