Modified Truss Head Self-Drilling Screws Price Estimates and Market Insights

Modified Truss Head Self-Drilling Screw An Overview

In the world of construction and manufacturing, the importance of choosing the right fastener cannot be overstated. Among the various types of fasteners available, the modified truss head self-drilling screw has gained considerable popularity due to its unique design and functionality. This article will delve into the advantages, applications, and considerations associated with modified truss head self-drilling screws.

What Are Modified Truss Head Self-Drilling Screws?

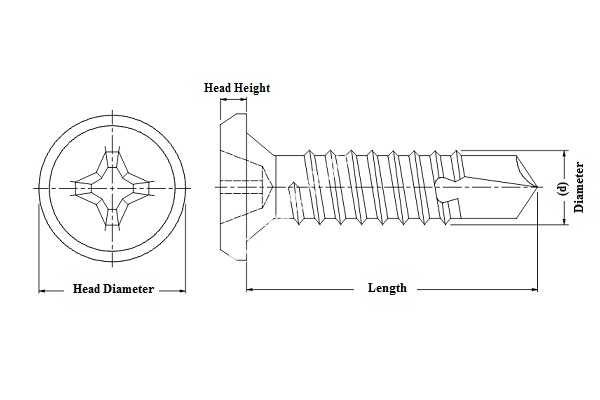

Modified truss head self-drilling screws are a specific type of fastener characterized by their large, flat head and the ability to drill into materials without the need for a pre-drilled hole. This is made possible by the sharp, aggressive drill point at the tip of the screw, which allows it to penetrate through various substrates effectively, such as metal sheets, wood, and plastic.

The modified truss head design combines the features of a traditional truss head with modifications that enhance its performance. The wider bearing surface provides better load distribution and minimizes the risk of stripping, while the unique shape of the head allows for easy installation with power tools.

Advantages of Modified Truss Head Self-Drilling Screws

1. Speed and Efficiency One of the primary benefits of using self-drilling screws is the significant reduction in installation time. Since these screws do not require pre-drilling, they can be driven directly into the material, speeding up the construction process and reducing labor costs.

2. Versatility Modified truss head self-drilling screws are suitable for a wide range of applications, including metal roofing, siding, framing, and structural assemblies. Their ability to work well in different materials makes them a favorite among contractors and builders.

3. Strong Grip The design of the modified truss head enhances the screw’s grip, making it reliable even in high-stress applications. The larger head provides better torque and minimizes the potential for slippage during installation.

modified truss head self drilling screw quotes

4. Corrosion Resistance Many of these screws are made from corrosion-resistant materials or are coated to withstand harsh environmental conditions. This feature is particularly important in outdoor or marine applications where exposure to the elements can significantly affect the longevity of the fastening system.

5. Cost-Effectiveness The efficiency of installation, combined with the durability of the screws, often leads to cost savings for projects. Fewer materials needed for pre-drilling and the reduction in labor hours can positively affect the overall budget.

Applications

Modified truss head self-drilling screws find use in multiple industries. In the construction sector, they are commonly used for attaching metal roofs and siding, securing structural components, and fastening insulation materials. In the manufacturing industry, these screws can be found in assembly lines where quick and reliable fastening is crucial. They are also utilized in DIY projects where ease of use and safety are major concerns.

Considerations

While modified truss head self-drilling screws present numerous advantages, there are some considerations to keep in mind. The specific material and thickness of the substrate play an essential role in determining the correct screw type. Additionally, the installation method and the torque applied must be appropriate for the screws to perform optimally without stripping or damaging the material.

Furthermore, it is essential to source these screws from reputable manufacturers to ensure quality and reliability. Cheaper alternatives may save money initially but could lead to greater costs in the long run due to failures or insufficient performance.

Conclusion

In conclusion, modified truss head self-drilling screws are a vital component in modern construction and manufacturing. Their unique design features ensure efficiency and reliability, making them a preferred choice for various applications. By understanding the benefits and appropriate uses of these screws, contractors and builders can make informed decisions that enhance the quality and longevity of their projects. Whether in residential or commercial construction, the incorporation of modified truss head self-drilling screws can lead to significant improvements in workflow and outcomes.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024