Manufacturers of Innovative Self-Drilling Screws with Modified Truss Head Design

Understanding Modified Truss Head Self-Drilling Screws An Overview of Their Importance and Manufacturers

In the construction and manufacturing industries, fasteners are essential components that unite materials to ensure stability and reliability. Among these fasteners, modified truss head self-drilling screws have gained significant popularity due to their unique design and functionality. This article will delve into the features of modified truss head self-drilling screws, their applications, and the importance of selecting reputable manufacturers for these products.

What Are Modified Truss Head Self-Drilling Screws?

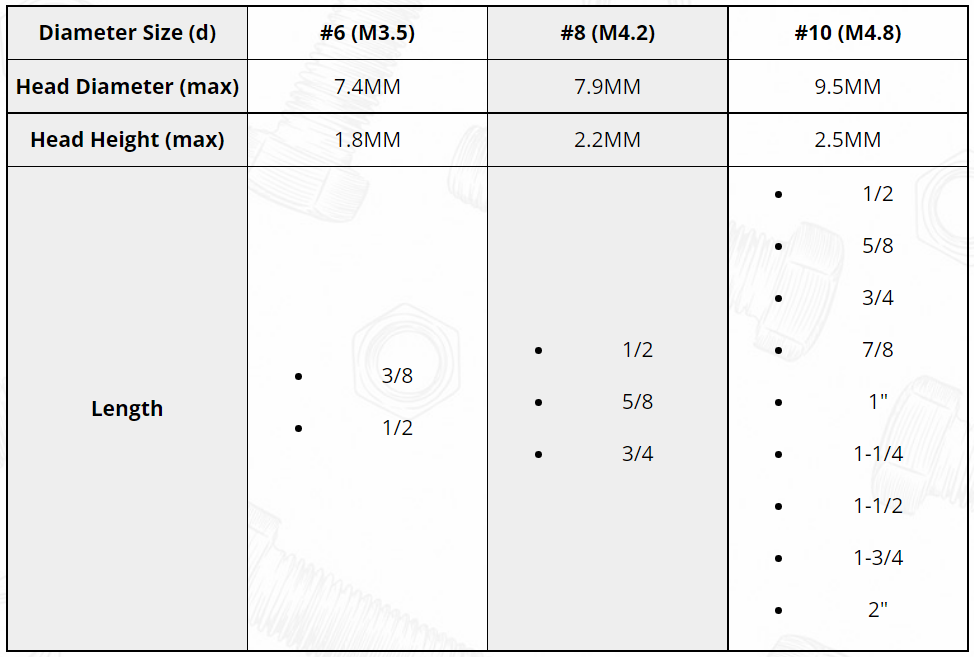

Modified truss head self-drilling screws are specialized fasteners designed for efficient and effective fastening in various materials, including metal, wood, and plastic. The truss head features a low profile with a broad bearing surface, which allows for even distribution of the load over a larger area, reducing the risk of material damage. The modified design enhances the screw's performance, making it ideal for applications where aesthetics and strength are crucial.

One of the key features of self-drilling screws is their integrated drill point, which eliminates the need for pre-drilling. This design allows for quicker installation, as the screws can penetrate the material with ease while creating their own hole. This not only saves time but also reduces the labor costs associated with traditional fastening methods that require pre-drilling.

Applications of Modified Truss Head Self-Drilling Screws

The versatility of modified truss head self-drilling screws makes them suitable for a wide range of applications. They are commonly used in the construction of metal buildings, roofing systems, and metal siding, where reliable fastening is essential. These screws are also popular in automotive and manufacturing industries, where precision and strength are paramount.

In addition to their use in metal applications, modified truss head self-drilling screws are also employed in wood construction and furniture manufacturing. The low-profile head design allows these screws to blend seamlessly into the surface of the material, making them invaluable for projects where aesthetic appeal is important.

Benefits of Modified Truss Head Self-Drilling Screws

1. Efficiency The self-drilling capability allows for faster installation times, thereby increasing productivity on job sites. Since there is no need for pre-drilling, workers can complete tasks more quickly.

2. Strength and Durability The robust design and material used in modified truss head self-drilling screws ensure that they can withstand significant loads and environmental conditions, making them a reliable choice for structural applications.

modified truss head self drilling screw manufacturers

3. Reduced Risk of Material Damage The broad bearing surface of the truss head minimizes the risk of the material cracking or splitting during installation, which is particularly important in wood and thin sheet materials.

4. Aesthetic Appeal The low-profile design helps achieve a smooth finish, making these screws suitable for visible applications where aesthetics matter.

Choosing the Right Manufacturer

Selecting the right manufacturer for modified truss head self-drilling screws is crucial for ensuring quality and reliability. Here are some factors to consider when evaluating manufacturers

1. Reputation Look for manufacturers with a solid reputation in the industry. Reading customer reviews and testimonials can provide insight into the quality of their products.

2. Certifications Opt for manufacturers that comply with relevant industry standards and possess necessary certifications. This indicates a commitment to quality and safety.

3. Range of Products A manufacturer that offers a wide range of fasteners, including different materials, sizes, and coatings, is likely to meet specific project requirements more effectively.

4. Customer Support Choose a manufacturer that provides excellent customer service, as this is crucial for addressing any inquiries or concerns that may arise during the purchasing process.

5. Experience Manufacturers with years of experience in producing self-drilling screws are more likely to have refined their processes and technologies to ensure high-quality products.

Conclusion

Modified truss head self-drilling screws play a significant role in various sectors, from construction to manufacturing. Their unique design, ease of installation, and robust performance make them a preferred choice for many applications. When sourcing these fasteners, it is essential to partner with reputable manufacturers who prioritize quality and reliability. By doing so, you can ensure that your projects are efficiently and securely fastened, contributing to overall success.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024