Exporter of M7 Self-Tapping Screws for Industrial and Commercial Applications

Exploring the Market for M7 Self-Tapping Screw Exporters

In the ever-evolving landscape of global manufacturing and construction, the demand for reliable and high-quality fasteners has never been higher. Among these fasteners, self-tapping screws, particularly M7 self-tapping screws, have carved out a significant niche. With applications ranging from industrial projects to DIY endeavors, understanding the role of M7 self-tapping screw exporters is crucial for both businesses and consumers alike.

Understanding M7 Self-Tapping Screws

M7 self-tapping screws are designed with a unique thread profile that allows them to create their own hole as they are driven into materials. This feature not only simplifies the installation process but also provides a strong and secure hold. Typically made from high-quality steel or other durable materials, these screws are resistant to corrosion and wear, making them ideal for use in various environments, including marine and outdoor applications.

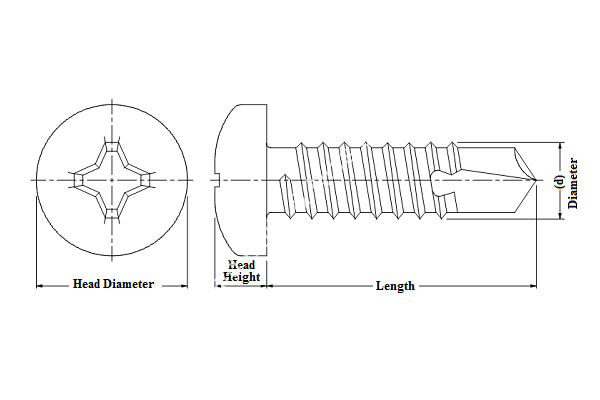

The M7 designation refers to the screw's diameter, which is 7mm. This size strikes a balance between strength and versatility, catering to a wide range of applications. M7 self-tapping screws are commonly used in metalworking, woodworking, and construction, as they can effectively fasten components without the need for pre-drilled holes. This advantage saves time and labor costs, which is particularly beneficial in large-scale projects.

The Role of Exporters

As industries around the world grow and global trade expands, exporters play a vital role in supplying M7 self-tapping screws to markets beyond their country of origin. Exporters are responsible for ensuring that these screws meet international quality standards, which is essential for maintaining the safety and integrity of various applications.

Successful M7 self-tapping screw exporters often have established relationships with manufacturers who specialize in producing high-quality fasteners. These relationships enable exporters to source products at competitive prices while adhering to rigorous quality control processes. Moreover, exporters must navigate complex logistics and customs regulations to ensure timely delivery to their international clients.

The Market Demand

The demand for M7 self-tapping screws is driven by several factors. The construction industry, in particular, has seen robust growth in recent years, fueled by urbanization and infrastructure development worldwide. As more construction projects emerge, the need for reliable fastening solutions like M7 self-tapping screws is increasingly important.

m7 self tapping screw exporter

In addition to construction, sectors such as automotive, electronics, and furniture manufacturing also contribute to the demand for self-tapping screws. For instance, in the automotive industry, lightweight and durable materials are essential; thus, M7 self-tapping screws offer an efficient solution for assembling components without adding unnecessary weight.

Quality Assurance and Compliance

For exporters, ensuring product quality is paramount. M7 self-tapping screws must comply with various international standards, such as ISO and ASTM, to guarantee their safety and performance. Engaging with accredited testing laboratories and obtaining necessary certifications can enhance the credibility of exporters in the eyes of potential buyers.

Furthermore, the trend towards sustainability is shaping consumer preferences, prompting exporters to adopt environmentally friendly practices. Sourcing screws made from recycled materials or providing packaging that is biodegradable or recyclable can appeal to eco-conscious customers, thus offering a competitive edge in the marketplace.

Challenges Faced by Exporters

Despite the opportunities in the M7 self-tapping screw market, exporters face several challenges. Fluctuations in material costs, changes in international trade policies, and logistics disruptions can impact profitability and supply chains. Additionally, the growing prevalence of counterfeit products presents a significant risk, as consumers may unknowingly purchase substandard screws that compromise safety and quality.

To combat these challenges, effective risk management strategies, market research, and robust supply chain practices are essential for exporters. By staying informed about market trends and customer needs, exporters can adapt their offerings accordingly and maintain a competitive position in the global market.

Conclusion

The M7 self-tapping screw market is a dynamic and essential component of various industries, with exporters playing a pivotal role in meeting global demand. By focusing on product quality, compliance, and sustainability, M7 self-tapping screw exporters can enhance their market presence and contribute to the ongoing growth of the manufacturing and construction sectors. As global trade continues to expand, the importance of reliable fasteners like M7 self-tapping screws will only grow, making this an exciting area for investment and development.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024