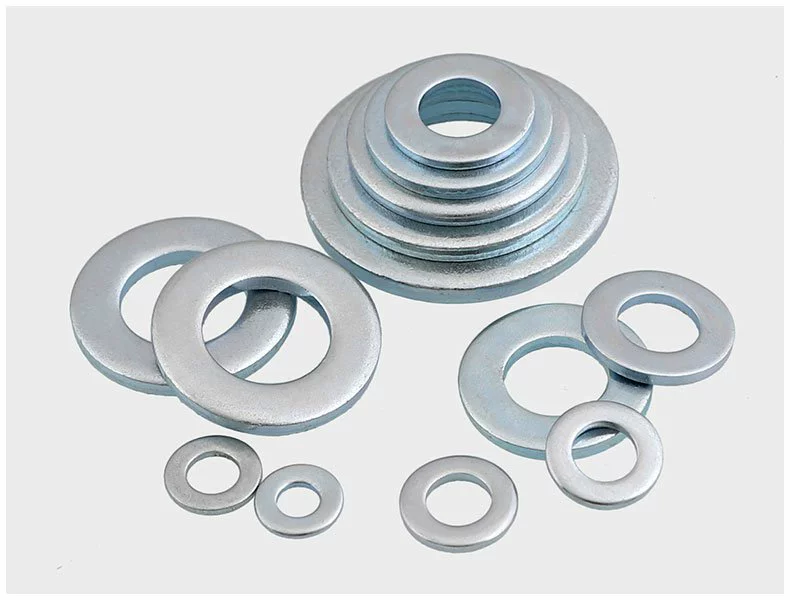

UNTERLEGSCHEIBE

The flat washer can disperse the pressure on the surface of the connected object when the screw or nut is tightened, and prevent the connected object from being damaged by excessive local pressure. For example, when the wooden board is connected with the metal frame, the flat washer can prevent the screw from directly pressing into the wooden board and causing it to break.

The flat washer can reduce the friction between the screw or nut and the surface of the connected object, reduce the wear, prolong the service life, and prevent the surface of the connected object from being scratched during turn of the screw.

Adjust the height and flatness of the connection: when there is a thickness difference or uneven surface between the two connected parts, the flat washer can be used to adjust the height to make the connection more compact and smooth.

Although the anti-loosening effect of flat washer is not as obvious as that of spring washer, it can also increase the stability of connection to a certain extent and reduce the looseness caused by vibration and other reasons when it is matched with appropriate screws and nuts and tightened to the specified torque.

-

Flache Unterlegscheiben sind ein wesentlicher Bestandteil jeder Befestigungsanordnung. Da sie dazu dienen, Abstand zu halten und die Last zu verteilen, wenn sie zwischen einer Mutter und einem Bolzen oder einer Schraube platziert werden, tragen sie dazu bei, Verschleiß und Verformung der Montageflächen im Laufe der Zeit zu verhindern.

-

Flache Unterlegscheiben sind ein wesentlicher Bestandteil jeder Befestigungsanordnung. Da sie dazu dienen, Abstand zu halten und die Last zu verteilen, wenn sie zwischen einer Mutter und einem Bolzen oder einer Schraube platziert werden, tragen sie dazu bei, Verschleiß und Verformung der Montageflächen im Laufe der Zeit zu verhindern.

Flat Washer Function

Prevent scratching and indentation: the flat washer can be used as a buffer layer and placed between the screw head and the surface of the connected object. In the process of tightening the screw, the screw head will exert pressure on the connected object. If there is no washer, the edge or rough surface of the metal screw head may scratch the connected object, especially some soft materials, such as wood, plastic or soft metal.

Uniformly distributing pressure: Flat gasket provides a wider pressure distribution area. When the screw is tightened, the applied pressure will be evenly transmitted to the surface of the connected object through the washer. This evenly distributed pressure is very important to ensure the stability and reliability of the connection. Taking the connection of automobile engine cylinder block as an example, by using flat washers, the pressure generated when tightening screws can act on the cylinder block and the connecting parts evenly, so as to prevent the parts from being deformed or sealed badly due to uneven pressure.

Adapt to the connection of materials with different hardness: when connecting materials with large hardness differences, the pressure dispersion effect of flat washers is more obvious. For example, when connecting metal and plastic materials, the metal material can bear large local pressure, while the plastic material is easy to be damaged under local high pressure. The flat washer can evenly distribute the pressure of the screw to the surface of the plastic material, so that the two materials can be closely connected without damaging the plastic part.

What Are the Specifications of Flat Washers?

Inner diameter size

The inner diameter of the flat washer is mainly determined according to the diameter of the bolt or screw used with it. Usually, the inner diameter of the flat washer will be slightly larger than the diameter of the bolt to facilitate installation. For example, for M5 (the bolt diameter is 5mm) bolts, the inner diameter of the matching flat washer is generally about 5.3-5.5mm, which can ensure that the washer can be smoothly sleeved on the bolt without shaking the bolt in the washer, and ensure the stability of the connection.

In some high-precision mechanical connections or special application scenarios, the tolerance requirements for the inner diameter of flat washers will be more stringent. For example, in the aerospace field, the tolerance of the inner diameter of the flat washer may be controlled within ±0.05mm or even less to meet the precise assembly requirements.

Outside diameter

There are many options for the outer diameter of flat washer, and its size will affect the effect of pressure dispersion. Generally speaking, the larger the outer diameter, the larger the area where the pressure is dispersed. Common outside diameter sizes range from a few millimeters to dozens of millimeters. For example, for the connection of small electronic equipment, a flat washer with an outer diameter of 6-10mm may be used; In the connection of building steel structure, the outer diameter may reach 30-50mm or even more.

Different standards also stipulate the proportional relationship between the outer diameter and the inner diameter of flat washers. In some standards, the outer diameter is about 1.5-2.5 times the inner diameter. For example, for a flat washer with an inner diameter of 10mm, its outer diameter may be between 15-25 mm. This size design can effectively play its functions of dispersing pressure while ensuring the rationality of the washer structure.

Thickness dimension

The thickness of flat washer also has many specifications. The thickness of thin flat washer may be about 0.5-1mm, and this kind of thin washer is often used in occasions with low requirements for connection height adjustment or limited space, such as the fixation of internal circuit boards in some small electronic products. However, the thickness of the thicker flat washer can reach 5-10mm, which is used in the scene where it is necessary to compensate for larger tolerances, adjust the connection height or bear greater pressure.

In some special application scenarios, flat washers with customized thickness will also be used. For example, in the connection of some parts of automobile engines, in order to achieve accurate sealing effect or adapt to specific installation space, flat washers with a thickness of 2-3mm are used, and the thickness tolerance is also strictly required, generally controlled at about 0.1 mm.