2 月 . 13, 2025 22:30

Back to list

self tapping sheet metal screw sizes

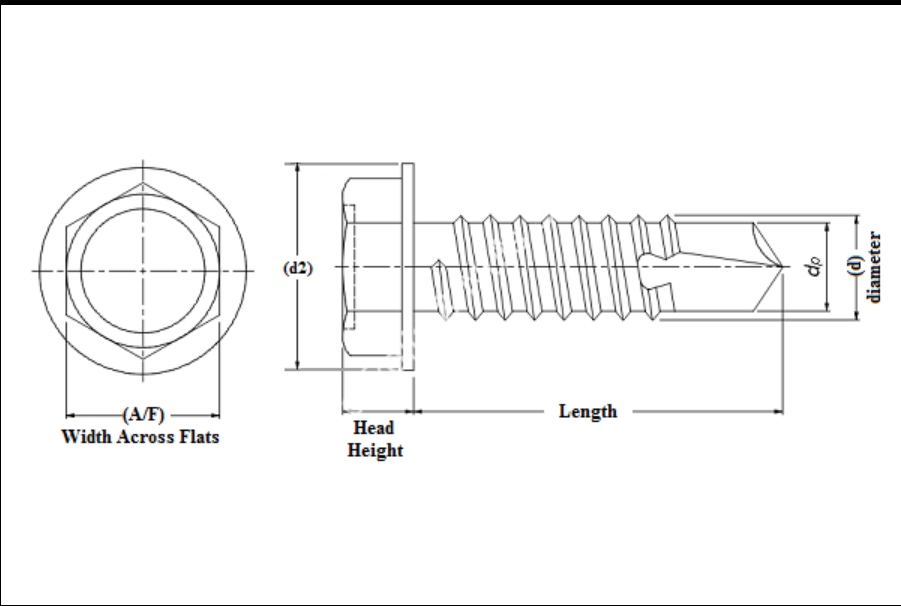

Self-tapping sheet metal screws are an essential component in various construction and manufacturing industries, known for their ability to create their own threads as they are driven into materials. Understanding the sizes and selection criteria of these screws can significantly impact the quality and strength of your project. This article delves into the nuances of self-tapping sheet metal screw sizes and offers insights based on extensive professional experience and industry expertise.

Popular finishes include zinc plating, which offers moderate corrosion resistance, and black oxide, which is suitable for aesthetic applications where a dark finish is preferred. Industry Applications and Expertise Recommendations Understanding the application context helps in deciding on the right screw size. For instance, when affixing lightweight aluminum sheets in HVAC systems, using a smaller diameter screw with a high TPI is advisable to prevent material deformation while ensuring a strong hold. For assembling heavier gauge steel components, a larger diameter with fewer TPI could provide the necessary strength without tearing the materials. Based on industry expertise, regularly inspecting and testing screws in their intended environment further assures their effectiveness. It is recommended that professionals unload one or a few screws during preliminary assembly stages to check compatibility with the materials and tools. Trust and Authority in Information Data on the reliability of self-tapping sheet metal screws reveals a trend towards using screws with specific coatings that enhance performance in demanding conditions. As such, selecting screws from reputable manufacturers known for quality control is paramount. Incorporating the latest engineering advances and industry best practices ensures projects meet both safety standards and durability expectations. Endorsements from construction engineers with hands-on experience can further substantiate claims regarding screw performance. Concluding, more than just understanding self-tapping sheet metal screw sizes, selecting the right screw requires a comprehensive approach considering material, application, expected loads, and environmental factors. By applying this knowledge, professionals not only ensure robust and long-lasting assemblies but also maintain the highest standards of workmanship and safety.

Popular finishes include zinc plating, which offers moderate corrosion resistance, and black oxide, which is suitable for aesthetic applications where a dark finish is preferred. Industry Applications and Expertise Recommendations Understanding the application context helps in deciding on the right screw size. For instance, when affixing lightweight aluminum sheets in HVAC systems, using a smaller diameter screw with a high TPI is advisable to prevent material deformation while ensuring a strong hold. For assembling heavier gauge steel components, a larger diameter with fewer TPI could provide the necessary strength without tearing the materials. Based on industry expertise, regularly inspecting and testing screws in their intended environment further assures their effectiveness. It is recommended that professionals unload one or a few screws during preliminary assembly stages to check compatibility with the materials and tools. Trust and Authority in Information Data on the reliability of self-tapping sheet metal screws reveals a trend towards using screws with specific coatings that enhance performance in demanding conditions. As such, selecting screws from reputable manufacturers known for quality control is paramount. Incorporating the latest engineering advances and industry best practices ensures projects meet both safety standards and durability expectations. Endorsements from construction engineers with hands-on experience can further substantiate claims regarding screw performance. Concluding, more than just understanding self-tapping sheet metal screw sizes, selecting the right screw requires a comprehensive approach considering material, application, expected loads, and environmental factors. By applying this knowledge, professionals not only ensure robust and long-lasting assemblies but also maintain the highest standards of workmanship and safety.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News