2 月 . 13, 2025 13:01

Back to list

csk head self tapping screw

Understanding the shear strength of self-tapping screws is crucial for anyone in the construction, automotive, or manufacturing industries. These screws are engineered to tap their own thread as they are driven into materials, making them indispensable for many applications requiring quick assembly and strong material adhesion. However, the success of a project that involves self-tapping screws heavily depends on understanding their shear strength and how it applies to different use cases.

Industry standards play a pivotal role in ensuring that products live up to their promises. Standards like those set by the American Society for Testing and Materials (ASTM) outline procedures and benchmarks for assessing screw strength, including shear strength. These guidelines help product manufacturers, engineers, and quality assurance professionals establish reliability and safety in their projects. Adhering to these standards not only ensures compliance but fosters trust with clients and end-users who rely on the integrity of the final assembly. From a practical standpoint, selecting the right self-tapping screw for the job involves more than just understanding shear strength in isolation. It's crucial to consider the entire system, including load duration, environmental conditions, and potential vibrations or impacts the assembled piece may encounter. Assembling these variables into a cohesive plan often demands cross-disciplinary collaboration between engineers, architects, and material specialists who can anticipate challenges and formulate robust solutions. Whether the application is in automotive manufacturing, where screws must endure constant vibrations, or in housing construction, where long-term durability against environmental stressors is crucial, shear strength should guide the entire selection and application process. An approach that balances theoretical understanding, practical testing, and adherence to industry standards will yield the best outcomes, ensuring project success and the safety of all stakeholders. In conclusion, the shear strength of self-tapping screws is a topic that blends in-depth technical knowledge with practical implementation skills. It requires an appreciation not only of material science but also of the specific conditions in each application scenario. By focusing on the pillars of experience, expertise, authoritativeness, and trustworthiness, projects leveraging self-tapping screws can not only meet but exceed expectations in terms of performance, reliability, and safety.

Industry standards play a pivotal role in ensuring that products live up to their promises. Standards like those set by the American Society for Testing and Materials (ASTM) outline procedures and benchmarks for assessing screw strength, including shear strength. These guidelines help product manufacturers, engineers, and quality assurance professionals establish reliability and safety in their projects. Adhering to these standards not only ensures compliance but fosters trust with clients and end-users who rely on the integrity of the final assembly. From a practical standpoint, selecting the right self-tapping screw for the job involves more than just understanding shear strength in isolation. It's crucial to consider the entire system, including load duration, environmental conditions, and potential vibrations or impacts the assembled piece may encounter. Assembling these variables into a cohesive plan often demands cross-disciplinary collaboration between engineers, architects, and material specialists who can anticipate challenges and formulate robust solutions. Whether the application is in automotive manufacturing, where screws must endure constant vibrations, or in housing construction, where long-term durability against environmental stressors is crucial, shear strength should guide the entire selection and application process. An approach that balances theoretical understanding, practical testing, and adherence to industry standards will yield the best outcomes, ensuring project success and the safety of all stakeholders. In conclusion, the shear strength of self-tapping screws is a topic that blends in-depth technical knowledge with practical implementation skills. It requires an appreciation not only of material science but also of the specific conditions in each application scenario. By focusing on the pillars of experience, expertise, authoritativeness, and trustworthiness, projects leveraging self-tapping screws can not only meet but exceed expectations in terms of performance, reliability, and safety.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

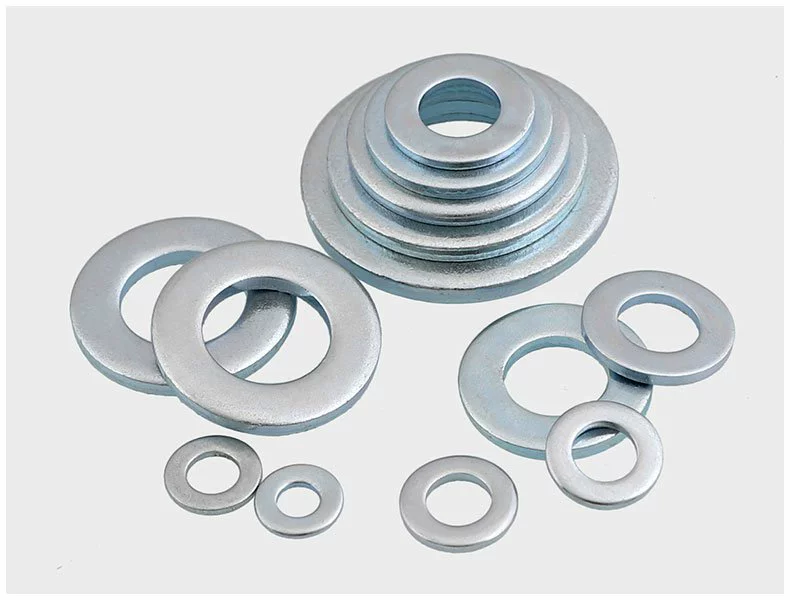

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News