self tapping screw m4 factories

Self-tapping screws, particularly in the M4 size, play a crucial role in various manufacturing and construction applications. As industries evolve, the demand for efficient fastening solutions continues to rise, leading to the establishment of specialized factories dedicated to producing high-quality self-tapping screws.

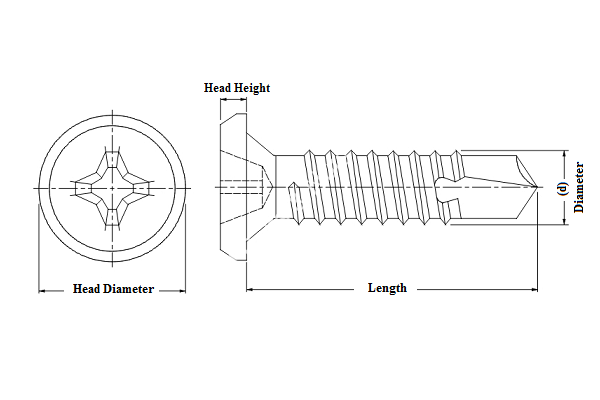

Self-tapping screws are designed to create their own hole as they are driven into materials, eliminating the need for pre-drilling. This feature not only saves time but also enhances the efficiency of assembly processes. The M4 self-tapping screw, with a diameter of 4mm, is particularly popular due to its versatility. It finds applications in numerous sectors, including automotive, electronics, and furniture manufacturing.

Self-tapping screws, particularly in the M4 size, play a crucial role in various manufacturing and construction applications. As industries evolve, the demand for efficient fastening solutions continues to rise, leading to the establishment of specialized factories dedicated to producing high-quality self-tapping screws.

Once the materials are chosen, they undergo a forming process where the desired screw shape is created. This is followed by heat treatment, which enhances the screw's mechanical properties, making it resistant to wear and tear. Surface coatings, such as zinc plating or black oxide, are applied to improve corrosion resistance and aesthetic appeal.

self tapping screw m4 factories

Quality control is a significant aspect of the manufacturing process. Factories employ rigorous testing protocols to ensure that each batch of screws meets industry standards and customer expectations. This includes tests for tensile strength, corrosion resistance, and thread integrity.

Moreover, with the growing emphasis on sustainable manufacturing practices, many factories are adopting eco-friendly methods. This includes recycling waste materials and minimizing energy consumption during production. By integrating sustainable practices, manufacturers not only comply with regulations but also meet the growing consumer preference for environmentally friendly products.

In conclusion, M4 self-tapping screw factories are pivotal in meeting the rising demand for efficient and reliable fastening solutions. Through advanced manufacturing techniques and a commitment to quality, these factories contribute significantly to various industries, ensuring that the products meet the highest standards for performance and sustainability. As technology continues to advance, the future of self-tapping screw production looks promising, with innovations that will further enhance their application across diverse sectors.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024