rivet vs self tapping screw

Rivets vs. Self-Tapping Screws A Comprehensive Comparison

When it comes to fastening materials in construction, manufacturing, and engineering, two popular options are rivets and self-tapping screws. Both have their unique advantages and applications, making them suitable for different tasks. This article takes an in-depth look at each fastening method, their benefits, drawbacks, and ideal use cases.

Understanding Rivets

Rivets are permanent mechanical fasteners that consist of a cylindrical shaft and a head. They are usually made of metal and are used primarily to join two or more pieces of material together. The installation of a rivet involves inserting it through pre-drilled holes in the materials being joined and then deforming the end of the shaft to form a second head, which locks the rivet in place.

Advantages of Rivets

1. Strength and Durability Rivets provide a strong and reliable bond, making them ideal for load-bearing applications. Once installed, they are resistant to vibration and can withstand significant shear and tensile forces.

2. Corrosion Resistance Many rivets are made from materials like aluminum or stainless steel, which are inherently resistant to corrosion, making them suitable for outdoor and marine applications.

3. No Threads Required Rivets do not require threaded holes, which simplifies the assembly process and can save time during installation.

4. Uniformity Riveted joints have a uniform appearance, which can be aesthetically pleasing in visible applications.

Disadvantages of Rivets

1. Permanent Fastening Once installed, rivets cannot be easily removed without damaging the materials. This makes repairs or adjustments more challenging.

3. Pre-Drilling Needed Rivets require pre-drilled holes, which adds an extra step in the fastening process.

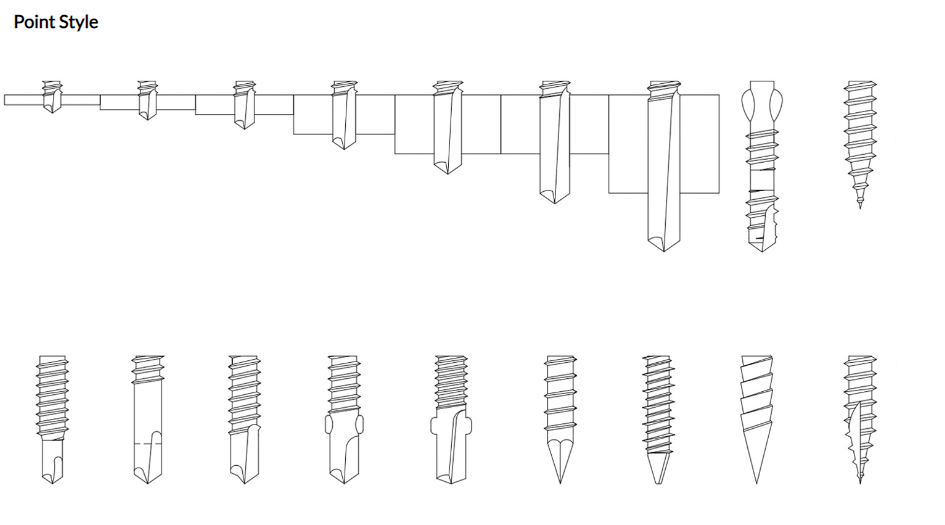

Understanding Self-Tapping Screws

rivet vs self tapping screw

Self-tapping screws, on the other hand, are designed to be driven directly into materials without the need for pre-drilled holes. They have threads along their length that allow them to create their own hole as they are driven in. This makes them a popular choice in various applications, particularly in wood and thin metal.

Advantages of Self-Tapping Screws

1. Ease of Installation Self-tapping screws can be quickly and easily installed using a standard screwdriver or power drill, which reduces labor time.

2. Removability Unlike rivets, self-tapping screws can be removed and reinserted multiple times. This flexibility is invaluable when modifications or repairs are needed.

3. Versatility They can be used in a wide range of materials, from softwoods to metals, making them suitable for various tasks.

4. Cost-Effectiveness Self-tapping screws are generally less expensive than rivets, especially when considering the savings on installation tools and time.

Disadvantages of Self-Tapping Screws

1. Strength Limitations While strong enough for many applications, self-tapping screws may not provide the same level of strength and durability as rivets, particularly in high-stress situations.

2. Potential for Strip Out The threads can become stripped, especially in softer materials, leading to a loose joint if not installed properly.

3. Corrosion Susceptibility Depending on the material, self-tapping screws may not offer the same level of corrosion resistance as some rivets, making them unsuitable for harsh environments without appropriate coatings.

Conclusion

Choosing between rivets and self-tapping screws involves considering the specific requirements of your project. Rivets are ideal for permanent joints requiring high strength and resistance to environmental factors, making them perfect for aerospace, automotive, and heavy construction applications. On the other hand, self-tapping screws excel in situations where ease of installation, flexibility, and cost-effectiveness are paramount.

Ultimately, the decision hinges on factors such as material type, load requirements, potential for disassembly, and environmental conditions. Understanding the unique properties and applications of each fastening method will lead to better outcomes in your fastening projects.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024