2 月 . 12, 2025 03:17

Back to list

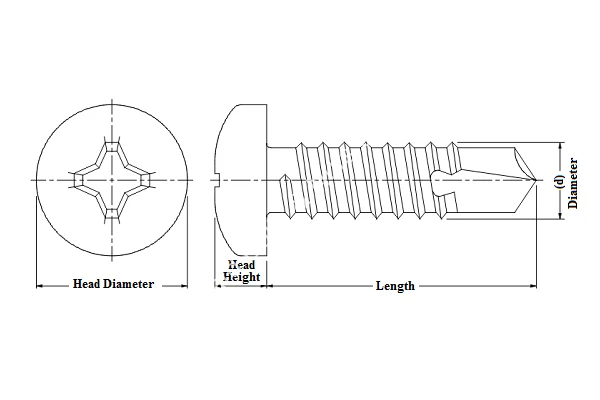

csk head self tapping screw

The decision between using a rivet and a self-tapping screw can significantly impact the performance, durability, and integrity of an assembled product. As two prevalent fastening solutions in the construction and manufacturing industries, each has distinct advantages and specific applications. Understanding these can lead to more efficient and effective designs.

From an expertise standpoint, choosing between rivets and self-tapping screws involves assessing the specific requirements of the project. You must consider factors such as the materials involved, the environment where the joint will function, load demands, and whether the joint will require future adjustments. For instance, in scenarios where joint failure could result in catastrophic outcomes, rivets might be the preferred choice. Yet, in a scenario where future adjustments are likely, a self-tapping screw could offer more flexibility and cost-effectiveness. Building trustworthiness in the selection process requires thoughtful evaluation and being informed by authoritative standards. Manufacturers and design professionals typically consult International Organization for Standardization (ISO) guidelines, ensuring that chosen fasteners meet stringent safety and quality standards. Industry-specific regulations and past successful applications also guide these choices. In practical experience, combining both fastening methods in a single project is sometimes the best strategy. For example, self-tapping screws might be used for initial assembly and alignment, while rivets are used in critical areas requiring enhanced strength. Selecting the right fasteners is more than a technical decision; it’s a fundamental step in ensuring product quality and longevity. Leveraging both personal experience and industry-tested guidelines can lead to improved designs and satisfied end-users. Through meticulous analysis and strategic implementation, the debate of rivet versus self-tapping screw becomes clearer, paving the way for innovative engineering solutions that stand the test of time.

From an expertise standpoint, choosing between rivets and self-tapping screws involves assessing the specific requirements of the project. You must consider factors such as the materials involved, the environment where the joint will function, load demands, and whether the joint will require future adjustments. For instance, in scenarios where joint failure could result in catastrophic outcomes, rivets might be the preferred choice. Yet, in a scenario where future adjustments are likely, a self-tapping screw could offer more flexibility and cost-effectiveness. Building trustworthiness in the selection process requires thoughtful evaluation and being informed by authoritative standards. Manufacturers and design professionals typically consult International Organization for Standardization (ISO) guidelines, ensuring that chosen fasteners meet stringent safety and quality standards. Industry-specific regulations and past successful applications also guide these choices. In practical experience, combining both fastening methods in a single project is sometimes the best strategy. For example, self-tapping screws might be used for initial assembly and alignment, while rivets are used in critical areas requiring enhanced strength. Selecting the right fasteners is more than a technical decision; it’s a fundamental step in ensuring product quality and longevity. Leveraging both personal experience and industry-tested guidelines can lead to improved designs and satisfied end-users. Through meticulous analysis and strategic implementation, the debate of rivet versus self-tapping screw becomes clearer, paving the way for innovative engineering solutions that stand the test of time.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News