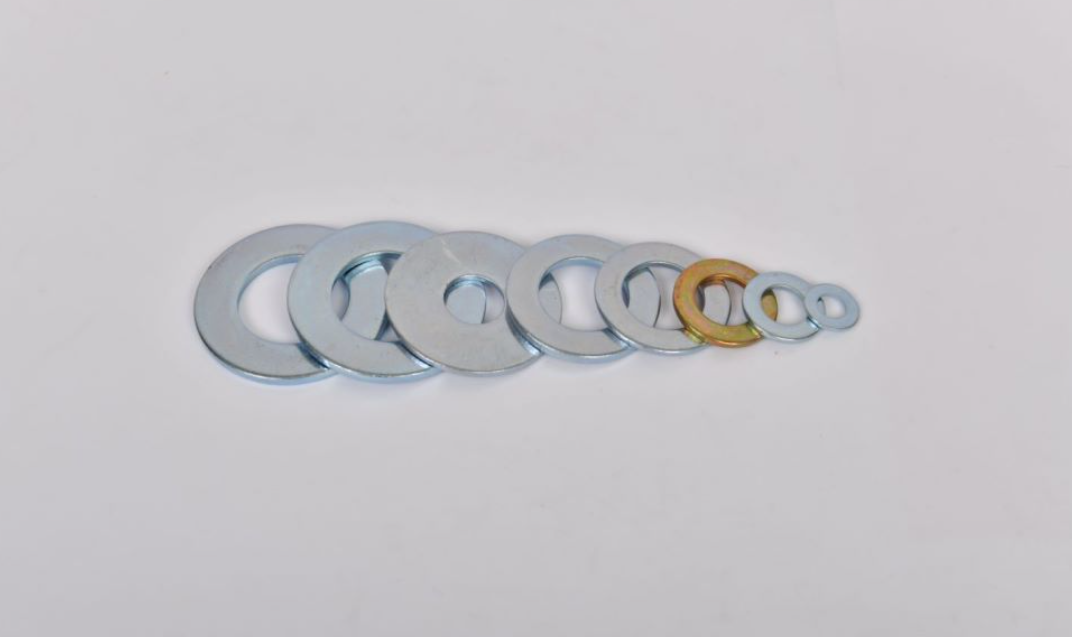

lock washer with flat washer products

Understanding Lock Washers with Flat Washers A Comprehensive Guide

In the world of mechanical engineering and assembly, fasteners play a critical role in ensuring the integrity and durability of structures and machines. Among the myriad of fastening components are lock washers and flat washers, both integral to achieving secure and reliable connections. This article aims to delve into the significance of these washers, their applications, and the benefits they provide, particularly when used in conjunction.

What are Lock Washers?

Lock washers are designed to prevent the loosening of screws, bolts, and nuts due to vibration or torque. These washers typically come in various shapes, including split, tooth, and wave designs. The primary function of a lock washer is to exert a spring-like force that keeps the fastener tight in its assembly, ensuring that mechanical joints remain secure even under stress.

The split lock washer, for example, features a single or dual split that creates a spring effect when compressed. This design allows it to expand and contract, effectively locking the fastener in place by increasing friction against the nut or bolt. Tooth lock washers, on the other hand, feature serrated edges that grip the surface of the fastened material, providing additional resistance to loosening.

What are Flat Washers?

Flat washers, generally round and thin pieces of metal, are utilized to distribute the load of a fastener. They are placed under the head of screws, bolts, or nuts to increase the surface area of the load-bearing surface. This distribution helps to prevent damage to the material being fastened, reduces the risk of loosening, and enhances the stability of the connection.

Flat washers come in various materials, including steel, stainless steel, and rubber, to suit different environments and applications. Their versatility makes them a preferred choice in assembling machinery, construction, and other engineering projects where load distribution is paramount.

The Synergy of Lock Washers and Flat Washers

While lock washers and flat washers can be used independently, their combination significantly enhances the performance and reliability of fastening applications. When used together, flat washers distribute the load evenly to minimize surface damage, while lock washers secure the fasteners against loosening from vibration or torque.

lock washer with flat washer products

For instance, in automotive applications, where engines generate substantial vibration, the use of both lock and flat washers ensures that critical components remain intact

. The flat washer provides a stable foundation while the lock washer prevents the fasteners from loosening over time, ultimately leading to enhanced vehicle safety and performance.Applications of Lock Washers with Flat Washers

The combination of lock washers with flat washers finds applications in numerous industries, including

1. Construction In structural assemblies where safety and stability are non-negotiable, this combination is crucial in securing beams, columns, and other components against dynamic loads.

2. Automotive Fastening engine parts and chassis components, where both vibration and torque are prevalent.

3. Aerospace Given the strict safety standards, the application of these washers ensures that aircraft components remain tightly secured during flight, minimizing the risk of failure.

4. Electronics In electronic devices, where vibration and thermal expansion can affect connections, using both washer types guarantees reliability in performance.

Conclusion

In summary, lock washers and flat washers are essential components in a wide range of mechanical and structural applications. Their unique properties complement each other, providing improved load distribution and preventing loosening in dynamic environments. As industries evolve and technologies advance, the use of these washers will continue to play a pivotal role in enhancing the integrity and durability of mechanical assemblies. Understanding their applications and benefits can lead to better design choices and more secure connections, essential for the safety and longevity of engineered systems.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024