lock washer and flat washer order factories

When considering the manufacturing and procurement of essential hardware components, such as lock washers and flat washers, it’s crucial to understand their significance in various applications. These washers play a vital role in ensuring the integrity and reliability of mechanical assemblies, making them integral to numerous industries, including automotive, aerospace, and construction.

Lock washers are designed to prevent bolted joints from loosening due to vibrations or rotational motion. They provide a locking mechanism that enhances the stability of assemblies in dynamic environments. On the other hand, flat washers are utilized to distribute the load of a fastener, protect the surface of the material being fastened, and prevent the loosening of nuts and bolts over time. Each type of washer serves a specific purpose, and selecting the right type is essential for achieving optimal performance.

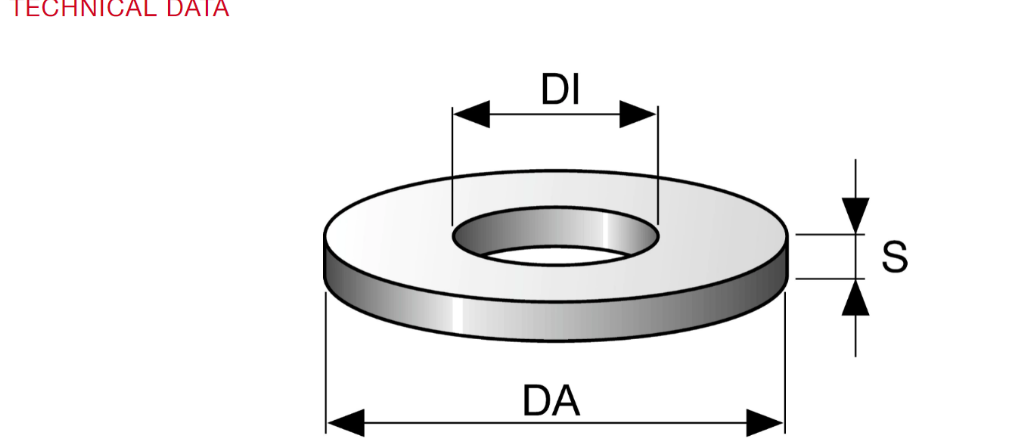

When ordering these washers from factories, it’s important to consider factors such as material composition, size, and manufacturing standards. Common materials used include steel, stainless steel, and various alloys, each offering different levels of strength and corrosion resistance. The dimensions of the washers, including inner and outer diameters as well as thickness, must align with the specifications of the intended application to ensure a proper fit.

Partnering with reputable manufacturers is essential for obtaining high-quality washers. It’s advisable to source from factories that adhere to industry standards and possess certifications that confirm their commitment to quality control. These factors are critical in ensuring that the products will perform as expected under operational conditions.

lock washer and flat washer order factories

Additionally, engaging with factories that offer custom manufacturing solutions can provide significant advantages, particularly for specialized applications. Custom options allow for the adaptation of washers to unique specifications, accommodating various project requirements.

Effective communication with suppliers is another key aspect of the ordering process

. Providing clear specifications and understanding the lead times for production and delivery are crucial to ensure that your project timelines remain intact.In summary, lock washers and flat washers are essential components in mechanical assemblies, and carefully selecting a qualified factory for manufacturing and procurement can significantly impact the success of your projects. Prioritizing quality, specifications, and strong supplier relationships will ultimately lead to improved performance and reliability in your applications.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024