drywall screw inspection factories

Drywall Screw Inspection Ensuring Quality in Manufacturing

In the construction industry, the importance of high-quality materials cannot be overstated. Among these materials, drywall screws play a critical role in the integrity of drywall installations. As a result, drywall screw inspection in factories has become a crucial step in ensuring that the products meet safety and quality standards. This article explores the significance of drywall screw inspection in manufacturing, the processes involved, and the implications of maintaining high-quality standards.

The Importance of Drywall Screws

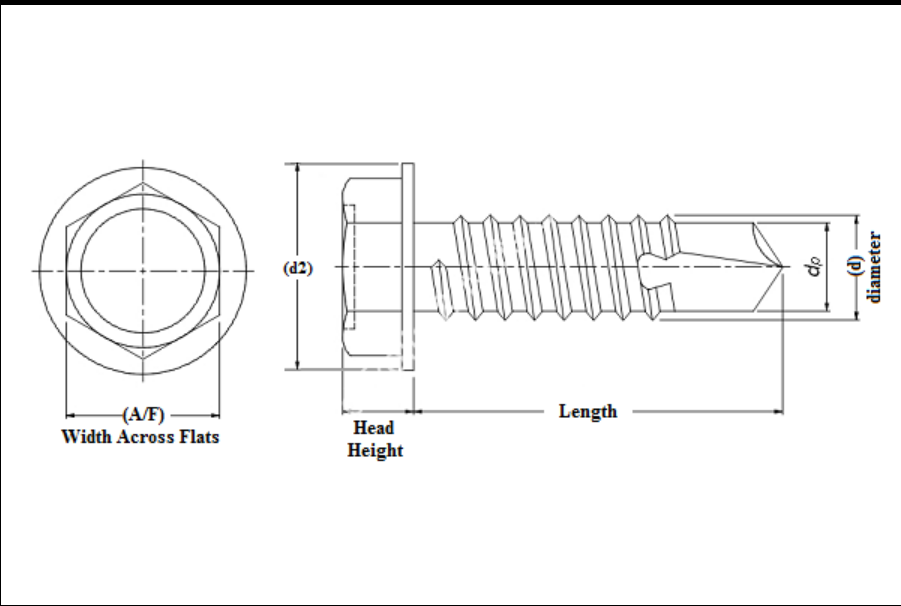

Drywall screws are designed to fasten drywall sheets to wooden or metal studs in construction projects. Their design typically includes a sharp point for easy penetration, coarse threads for better hold, and a bugle head that allows for flush installation. While they may seem like a minor component in the construction industry, the reliability of these screws is paramount. Faulty or substandard screws can lead to structural failures, which may result in safety hazards and costly repairs.

The Inspection Process

The drywall screw inspection process in factories encompasses several stages, from raw material selection to the final product testing. Each stage is vital in ensuring that the screws meet the stringent quality requirements necessary for their intended applications.

1. Raw Material Selection The first step involves sourcing high-quality steel, which is often coated to enhance corrosion resistance. Inspectors evaluate the material for its durability and strength, as these factors directly influence the performance of the screws.

2. Production Quality Control During the manufacturing phase, continuous quality checks are essential. This includes monitoring machinery settings, inspecting the dimensions of screws, and ensuring that the threading is uniform. Any deviations from specifications can compromise the screw's effectiveness.

3. Mechanical Testing After production, a sample of screws is subjected to various mechanical tests. These may include tensile strength tests, shear tests, and torque tests. The results of these tests are critical in verifying that the screws can withstand the forces they will encounter in real-world applications.

4. Visual Inspection A thorough visual inspection is performed to identify any cosmetic defects, such as surface blemishes, improper coatings, or dimensional inaccuracies. This step is crucial, as even minor imperfections can affect performance.

drywall screw inspection factories

5. Packaging and Labeling Finally, screws that pass all inspection stages are carefully packed and labeled. Packaging not only prevents damage during shipping but also provides essential information about the product, including specifications and safety warnings.

The Role of Technology in Inspection

Advancements in technology have significantly improved the efficiency and accuracy of drywall screw inspection. Automated inspection systems equipped with sensors and cameras can quickly detect defects that may be missed during manual inspections. These systems can evaluate the screws at high speed, allowing for a more extensive sample size and faster feedback to the manufacturing process.

Additionally, data analytics plays a crucial role in quality assurance. Manufacturers can track inspection results over time to identify patterns or recurring issues, enabling them to make informed decisions about process improvements.

Implications of Quality Control

The implications of stringent drywall screw inspection extend beyond the factory floor. High-quality screws contribute to the overall safety and durability of construction projects. In an industry where mistakes can have devastating consequences, ensuring that every screw meets quality standards is not just a matter of compliance but a commitment to safety.

Moreover, reputable manufacturers who prioritize inspection and quality control can enhance their brand reputation and build trust with customers. In a competitive market, this can be a decisive factor for construction companies when selecting suppliers.

Conclusion

In conclusion, drywall screw inspection in factories is a fundamental aspect of manufacturing that ensures the safety, reliability, and integrity of construction materials. From raw material selection to mechanical testing and visual inspections, every step in the process plays a vital role in delivering a high-quality product. With the integration of advanced technology and data analysis, manufacturers can enhance their inspection processes, ultimately benefiting the broader construction industry. By prioritizing quality control, we can ensure that the structures we build are not only aesthetically pleasing but also safe and durable for years to come.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024