7/16 self tapping screw company

The Versatile World of 7/16% Self-Tapping Screws A Closer Look at an Unsung Hero in Fastening Technology

In the realm of construction and manufacturing, small components often play a vital role in achieving structural integrity and functionality. Among these components, self-tapping screws are essential tools that facilitate a range of applications, making them indispensable in various industries. This article delves into the significance of 7/16% self-tapping screws, highlighting their features, applications, and the companies that specialize in their production.

Understanding Self-Tapping Screws

Self-tapping screws are unique fasteners designed to create their own hole as they are driven into materials, eliminating the need for pre-drilling. This self-threading capability makes them particularly useful for fastening a variety of materials, including wood, metal, and plastics. The design typically incorporates sharp threads and a pointed tip, allowing penetration into the material without additional tools. The unique 7/16% designation refers to the screw's dimensions, denoting the size of the screw's head or shaft relative to its threading capability, which is critical for ensuring compatibility with different applications.

Advantages of 7/16% Self-Tapping Screws

One of the primary advantages of 7/16% self-tapping screws is their time-saving attributes. By eliminating the need for drilling pilot holes, these screws expedite the assembly process, allowing for faster construction and manufacturing timelines. This efficiency is particularly beneficial in high-volume production environments, where every second counts.

Moreover, their design provides a secure fastening solution that withstands vibration and environmental factors. This makes them ideal for applications in automotive manufacturing, construction, electronics, and beyond. Additionally, self-tapping screws often feature coatings that enhance corrosion resistance, thereby extending the lifespan of the products they secure.

Applications Across Industries

The versatility of 7/16% self-tapping screws extends across various industries. In the construction sector, they are frequently used to attach drywall, roofing, and metal studs, ensuring robust structural integrity. Their self-sealing capabilities also make them suitable for outdoor applications, where exposure to the elements is a concern.

7/16 self tapping screw company

In the automotive industry, self-tapping screws are critical for assembling various components, such as interior panels and electrical housings. Their ability to create secure connections in lightweight materials contributes to the overall efficiency of vehicle assembly. Additionally, in electronics manufacturing, they provide an ideal solution for fastening components to circuit boards and other substrates, where precision and reliability are paramount.

Leading Companies in Self-Tapping Screw Manufacturing

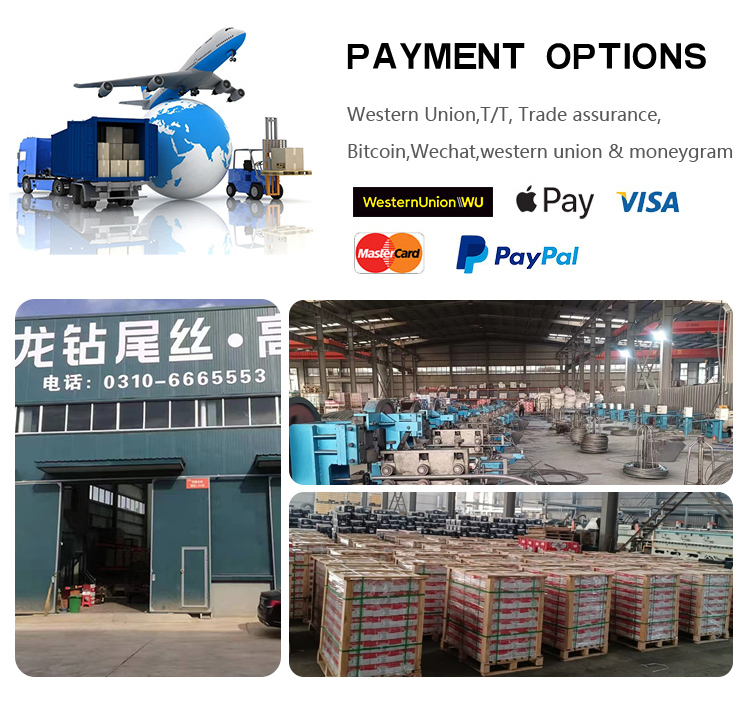

Several companies have established themselves as leaders in the production of self-tapping screws, including those focusing specifically on the 7/16% variety. These companies combine advanced technology with years of expertise to create high-quality fasteners that meet stringent industry standards.

1. Fastener Innovations Inc. Specializing in high-performance fastening solutions, Fastener Innovations offers a range of self-tapping screws, including custom solutions tailored to specific applications. Their commitment to quality control ensures consistent performance.

2. ScrewTech Corporation ScrewTech is renowned for its innovative designs and high-quality manufacturing processes. They provide an extensive catalog of self-tapping screws suitable for various industries, ensuring customers find the right product for their needs.

3. Precision Fasteners Ltd. This company emphasizes precision engineering and offers a diverse selection of self-tapping screws designed for critical applications. Their focus on durability and reliability has positioned them as a preferred supplier for many manufacturers.

Conclusion

As industries continue to evolve, the importance of efficient and reliable fastening solutions like 7/16% self-tapping screws cannot be overstated. Their time-saving characteristics, combined with their versatility and strength, make them an essential component in modern construction and manufacturing processes. Leading companies in the field are dedicated to producing high-quality fasteners that not only meet but exceed industry standards, ensuring that projects are completed safely and effectively. In summary, while often overlooked, self-tapping screws are vital players in the intricate machinery of production and design, illustrating that even the smallest components can have an outsized impact on industry dynamics.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024