3.5 self tapping screw products

Understanding 3.5% Self-Tapping Screws A Comprehensive Overview

Self-tapping screws are essential components in various industries, renowned for their ability to create their own mating thread in materials such as wood, plastic, and metal. Among the diverse array of self-tapping screws available on the market, the 3.5% self-tapping screw is notable for its unique features and applications.

What are Self-Tapping Screws?

Self-tapping screws are specialized fasteners designed to drill their own hole into the material they're being driven into. Unlike standard screws that require a pre-drilled hole, self-tapping screws can penetrate harder materials and form a tight grip. This capability significantly enhances efficiency, saving both time and effort in assembly processes.

The Basics of 3.5% Self-Tapping Screws

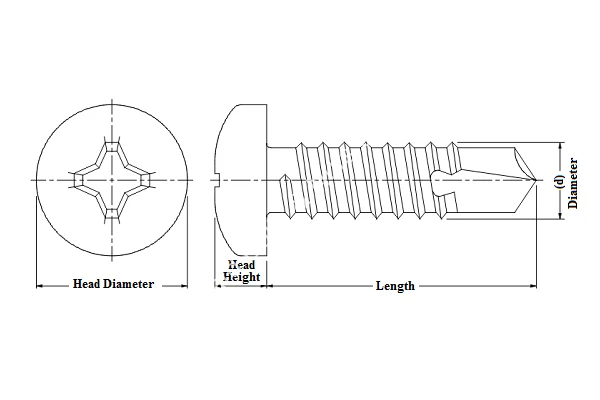

The designation 3.5% in self-tapping screws refers to the thread size and design. Generally, in the world of screws, various dimensions and shapes are critical to their functionality, and 3.5% screws typically indicate a small diameter, ideal for lighter applications. These screws are often manufactured to specific standards, ensuring quality and reliability.

3.5% self-tapping screws are commonly found in various materials and finishes. They may feature zinc plating for corrosion resistance or be made from stainless steel for added durability. The choice of material often depends on the application's environment. For example, in outdoor applications, rust resistance is paramount, so stainless steel or coated screws would be preferred.

Applications of 3.5% Self-Tapping Screws

Due to their versatile nature, 3.5% self-tapping screws cater to numerous sectors. Here are a few key applications

1. Woodworking In woodworking, 3.5% self-tapping screws are ideal for joining wood components together. They can effectively grip without the need for pre-drilling, which streamlines the assembly process.

3.5 self tapping screw products

2. Electronics In the electronics industry, these screws are frequently used to secure covers and fixtures. Their small size makes them perfect for applications where space is limited, and precision is critical.

4. Construction In construction, 3.5% self-tapping screws are employed for attaching metal to metal, particularly in metal roofing applications and building frameworks, where their ability to tap their own threads into metal significantly speeds up installation.

Advantages of Using 3.5% Self-Tapping Screws

- Time Efficiency The primary advantage of self-tapping screws is the speed of installation. By eliminating the need for pre-drilled holes, they can save significant time during assembly.

- Versatility Their ability to work in various materials makes them highly versatile. Whether dealing with thin metal sheets, wooden constructions, or plastic fixtures, 3.5% self-tapping screws are up to the task.

- Strong Grip When properly installed, these screws form a robust connection, holding materials tightly together and resisting pull-out forces.

- Cost-Effective The reduction in labor and potential for faster assembly often leads to lower overall project costs, making self-tapping screws a cost-effective choice.

Conclusion

3.5% self-tapping screws are indispensable in many sectors due to their unique properties and multiple applications. The ability to tap their threads while driving into materials ensures that these screws provide a strong, reliable fastening solution. Whether in woodworking, electronics, automotive, or construction, these screws enhance efficiency, reduce labor costs, and maintain structural integrity. As industries continue to evolve, the demand for versatile, efficient fastening solutions like 3.5% self-tapping screws will undoubtedly persist, making them a crucial component in modern manufacturing and construction practices.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024