High-Quality Self-Tapping Screws for Durable Machine Applications

Understanding 10-32 Self-Tapping Machine Screws Features, Uses, and Benefits

In the realm of fasteners, self-tapping screws play a pivotal role due to their versatility and ease of use. Among the various sizes available, the 10-32 self-tapping machine screw is a popular choice in many industries, including construction, automotive, electronics, and DIY projects. This article delves into the characteristics, applications, and advantages of using 10-32 self-tapping machine screws.

What is a 10-32 Self-Tapping Machine Screw?

The designation “10-32” references the screw's diameter and thread count. Specifically, the 10 indicates that the screw has a nominal diameter of 0.1900 inches, while the 32 signifies that there are 32 threads per inch. The self-tapping feature allows the screw to cut its own thread when driven into materials such as metal, plastic, or wood. This capability simplifies installation, making self-tapping screws a favored choice among professionals and hobbyists alike.

Types of Self-Tapping Screws

Self-tapping screws come in various forms, tailored for specific materials and applications. The predominant types include

1. Sheet Metal Screws Designed for fastening metal sheets, these screws are widely used in the manufacturing and automotive sectors. 2. Wood Screws These screws have coarse threads and are used primarily for woodworking applications, providing a secure grip in wooden structures. 3. Machine Screws These are typically used with pre-tapped holes and can be driven into hard materials without the need for a pilot hole.

The 10-32 size often fits into the machine screw category, making it exceptionally suitable for projects involving metal and machinery.

Applications of 10-32 Self-Tapping Machine Screws

With versatility at the forefront, 10-32 self-tapping machine screws find extensive use across various domains

10-32 self tapping machine screw products

- Automotive Industry Used to secure body panels and engine components, these screws withstand vibrations and temperature fluctuations. - Electronics Essential for assembling devices, electronics often require self-tapping screws for securing circuit boards or casings without damaging delicate components. - Construction In building and structural applications, these screws provide strength and ease of installation, whether in fixtures, frameworks, or cladding.

Benefits of Using 10-32 Self-Tapping Machine Screws

1. Efficiency in Installation One of the most significant advantages of self-tapping screws is the reduced need for pre-drilling, saving both time and labor costs during assembly or installation.

2. Cost-Effectiveness With their ability to create threads as they are installed, 10-32 self-tapping screws minimize the need for additional hardware or tools, further reducing expenses.

3. Secure Fastening The design ensures a tight fit, providing reliable and durable fastening, crucial in applications where safety and integrity are paramount.

4. Wide Availability Available in a variety of materials including stainless steel, zinc-plated steel, and brass, 10-32 self-tapping screws cater to diverse environmental needs, including resistance to corrosion and rust.

5. User-Friendly Design Their straightforward design makes them accessible for both professional and novice users, allowing individuals to engage in projects without requiring specialized knowledge of fastening techniques.

Conclusion

In summary, 10-32 self-tapping machine screws are an invaluable resource for various applications ranging from construction to electronics and beyond. Their simplicity, efficiency, and reliability make them a preferred fastener in a multitude of settings. By simplifying the installation process and enhancing security, these screws exemplify how small components can make a significant impact in construction and manufacturing. Whether you are a seasoned professional or a DIY enthusiast, integrating 10-32 self-tapping machine screws into your projects will undoubtedly yield effective results.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

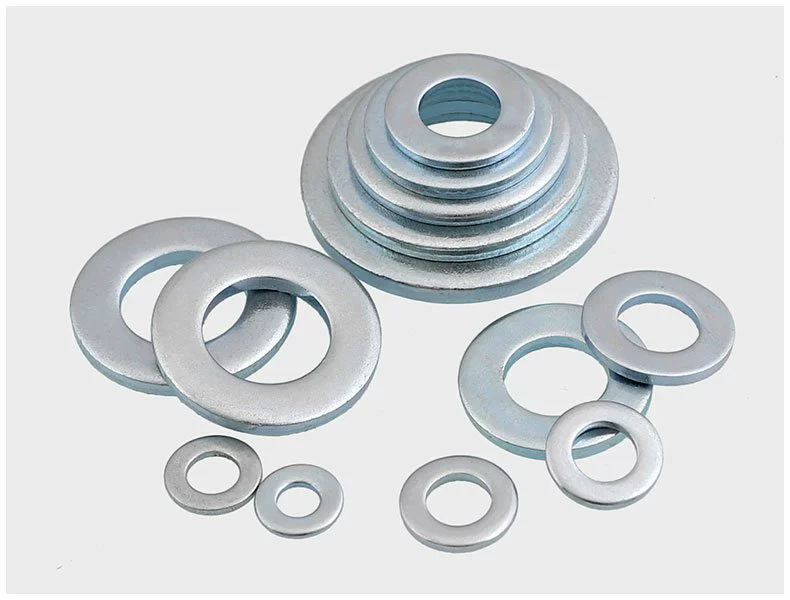

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024