Self Tapping Phillips Pan Head Screw Suppliers and Manufacturers for Various Applications

The Importance of Phillips Pan Head Self-Tapping Screws in Modern Manufacturing

In the realm of manufacturing and construction, the significance of using reliable and efficient fasteners cannot be overstated. Among the various types of fasteners available, Phillips pan head self-tapping screws stand out for their unique design and functionality. This article delves into the features, applications, and the role of manufacturers in bringing these effective fasteners to various industries.

Understanding Phillips Pan Head Self-Tapping Screws

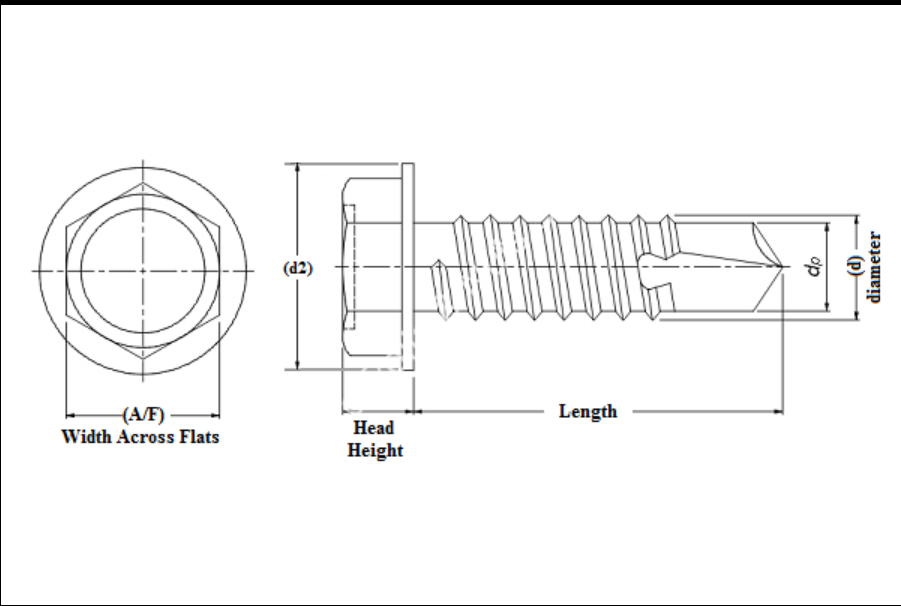

Phillips pan head self-tapping screws are designed with a distinct Phillips drive and a rounded head, which allows for a more extensive contact surface than flat-head screws. This design not only enhances grip but also allows for efficient drilling into materials without the need for a pre-drilled pilot hole. The self-tapping feature enables these screws to create their own thread as they are driven into the material, making them exceptionally useful in a wide range of applications.

The Phillips drive allows for a more positive engagement with the screwdriver. The cross-shaped configuration provides better control and reduces the risk of slippage, which is particularly beneficial when working in tight spaces. The pan head’s rounded shape also allows the screw to sit flush with the surface, providing a clean finish.

Applications in Various Industries

Phillips pan head self-tapping screws are utilized in diverse sectors, ranging from construction and automotive to electronics and furniture manufacturing. Their versatility stems from their ability to fasten a variety of materials, including metal, plastic, and wood.

1. Construction In construction, these screws are vital for securing structural elements, as they can penetrate various substrates quickly and efficiently. They are commonly used in framing, roofing, and installing drywall.

2. Automotive The automotive industry relies on self-tapping screws for assembling components, where reliable fastening is critical for safety and performance. Their ability to withstand vibrations and stress makes them ideal for automotive applications.

3. Electronics In electronics, precision and reliability are paramount. Phillips pan head self-tapping screws are often used in assembling casings and securing internal components, ensuring that devices are properly assembled and function optimally.

phillips pan head self tapping screw manufacturers

4. Furniture Manufacturing The furniture industry benefits from these screws due to their ability to provide a sturdy hold without the need for a pre-drilled hole. This not only saves time but also ensures that the final product is aesthetically pleasing.

The Role of Manufacturers

Manufacturers play a crucial role in the production of Phillips pan head self-tapping screws. They are responsible for the selection of high-quality materials, precise manufacturing processes, and rigorous quality control to produce dependable products.

1. Material Selection The choice of material can greatly impact the performance of self-tapping screws. Manufacturers typically use materials like stainless steel, carbon steel, or specialized alloys to ensure corrosion resistance and durability.

2. Manufacturing Process Modern manufacturing techniques, such as cold heading and heat treatment, enhance the strength and performance of these screws. Advanced machinery and technology enable manufacturers to produce screws with consistent quality and precision.

3. Quality Control Manufacturers adopt stringent quality control measures to ensure that every screw meets industry standards and specifications. This may involve testing for tensile strength, corrosion resistance, and dimensional accuracy, ensuring that the final product is reliable and safe for use in critical applications.

4. Custom Solutions Many manufacturers offer custom self-tapping screw solutions to meet specific requirements from various industries. This flexibility allows for innovation and adaptation to the ever-changing needs of the market.

Conclusion

Phillips pan head self-tapping screws are indispensable in various sectors due to their unique design and functionality. Their ability to streamline the fastening process while providing reliable security makes them a preferred choice among professionals. The role of manufacturers in producing high-quality screws cannot be understated, as they ensure that these fasteners meet the demands of modern manufacturing and construction. As industries continue to evolve, the importance of durable and efficient fasteners, such as Phillips pan head self-tapping screws, will only continue to grow.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024