Self-tapping Screw Dimensions and Specifications for No. 206 Products

Understanding No. 206 Self-Tapping Screw Dimensions

Self-tapping screws are an essential component in various industries, ranging from construction to electronics. These screws, designed to create their own threaded hole in materials, provide a streamlined and efficient fastening solution. Among the myriad types of self-tapping screws available, the No. 206 self-tapping screw stands out due to its unique dimensions and features. In this article, we will explore the dimensions of No. 206 self-tapping screws, their applications, and considerations for usage.

Dimensions of No. 206 Self-Tapping Screws

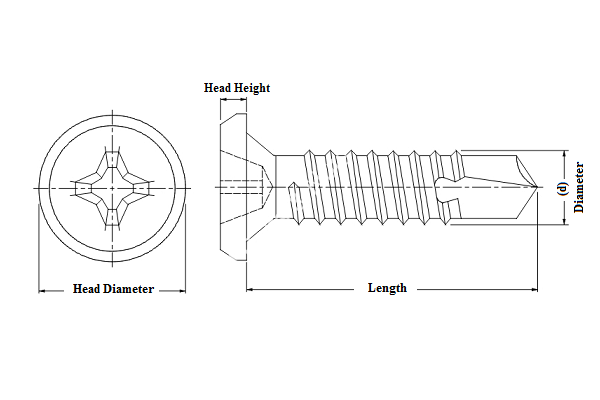

The No. 206 self-tapping screw typically features a thread diameter of approximately 3.5 mm (0.138 inches) and a length that can vary between 10 mm (0.394 inches) to 25 mm (0.984 inches). The head type of these screws is often hexagonal or slotted, allowing for versatile applications and easy installation. The most common head diameter is about 7.4 mm (0.291 inches), which is designed to provide a large surface area for better torque application without damaging the material being fastened.

The pitch, or the distance between threads, for No. 206 screws usually measures around 0.8 mm (0.031 inches). This specific pitch allows for deeper penetration and a more secure grip in various materials, including wood, metal, and plastic. Additionally, the screw’s shank may have variations, such as being partially threaded or fully threaded, depending on the application requirements.

Applications of No. 206 Self-Tapping Screws

One of the most significant advantages of No. 206 self-tapping screws is their versatility. They are commonly used in wood assembly, metal fabrication, and even in plastic products. Due to their ability to tap their own thread, they eliminate the need for pre-drilled holes in many situations, thus speeding up the assembly process and reducing manual labor.

In the construction industry, No. 206 screws are often used for securing drywall, attaching fixtures, or fastening components in roofing applications. The adaptability of these screws allows them to work efficiently with thin sheets of material, making them an ideal choice for light to medium-duty applications.

no 6 self tapping screw dimensions products

In automotive and appliance manufacturing, self-tapping screws are crucial for assembling components quickly and securely. Their straightforward installation process minimizes production time, making them a preferred choice for manufacturers looking to enhance efficiency without compromising quality.

Considerations for Using No. 206 Self-Tapping Screws

While No. 206 self-tapping screws offer numerous benefits, there are important factors to consider when using them. First, it is essential to match the screw type to the material being fastened. Using a screw that is too long or too short can compromise the joint's integrity. Additionally, ensuring that the material's thickness is appropriate for the screw's length is vital to prevent breakage or stripping during installation.

Next, it is crucial to select the appropriate installation tool. A power driver can significantly ease the installation process, but care must be taken to use the right torque settings to prevent damaging the screw or the material. Additionally, using a pilot hole may be beneficial in harder materials to ensure proper alignment and reduce the risk of splitting.

Finally, consider the environmental conditions in which the screws will be used. Some self-tapping screws are treated or coated to resist corrosion, while others may rust when exposed to moisture. Selecting screws with appropriate coatings for outdoor or humid environments can help prolong their lifespan.

Conclusion

No. 206 self-tapping screws are a highly effective fastening solution, offering convenience, strength, and versatility across various applications. Understanding their dimensions and suitability for specific tasks can aid manufacturers and contractors in making informed choices. By considering the material, installation tools, and environmental factors, one can maximize the benefits of using No. 206 self-tapping screws, leading to more secure and efficient assembly outcomes.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024