Yellow Galvanized Chipboard Nail Suppliers and Their Quality Standards

Yellow Galvanized Chipboard Nail Manufacturers An Overview

In the world of construction and woodworking, fasteners play a crucial role in ensuring the stability and integrity of structures. Among these, nails are the most commonly used fasteners, and their specifications can vary greatly based on the intended application. One particular type gaining popularity is the yellow galvanized chipboard nail, known for its durability and resistance to corrosion.

What Are Yellow Galvanized Chipboard Nails?

Yellow galvanized chipboard nails are specifically designed for use with chipboard and other engineered wood products. The yellow galvanized finish indicates that these nails are coated with a layer of zinc, which provides significant protection against rust and corrosion. This coating not only enhances the nails’ lifespan but also makes them suitable for various indoor and outdoor applications.

The unique coloring of the yellow finish not only serves an aesthetic purpose, allowing it to blend well in certain environments, but also signifies its resistance to corrosion, making it an ideal choice for applications where moisture may be a concern. These nails are typically used in furniture manufacturing, cabinetry, and flooring installations.

The Manufacturing Process

The production of yellow galvanized chipboard nails involves several critical steps to ensure their quality and usability. Manufacturers begin with high-quality steel wire, which is drawn into the desired nail sizes. The nails are then shaped using machines that forge them into precise dimensions, ensuring consistency and reliability in their performance.

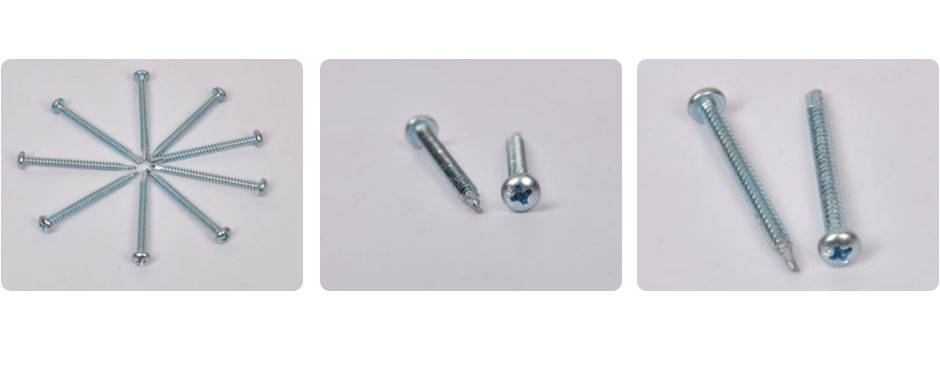

yellow galvanized chipboard nail manufacturers

Once shaped, the nails undergo a galvanization process. This involves dipping the nails into a molten zinc bath or applying a zinc coating through electro-galvanization. The yellow hue is achieved by applying a specific finish that also provides additional hardness to the coating. Quality control checks are essential during this process, as manufacturers test for factors such as tensile strength, coating adhesion, and corrosion resistance.

Choosing the Right Manufacturer

When looking for yellow galvanized chipboard nail manufacturers, it is essential to consider several factors. First, choose a manufacturer with a proven track record in the industry. This can often be determined by their reputation and the feedback from previous customers.

Second, check for quality certifications and standards compliance. Reputable manufacturers typically adhere to international standards, ensuring that their products meet safety and performance guidelines.

Lastly, consider the range of products offered. While focusing on yellow galvanized chipboard nails, it can be beneficial to work with manufacturers that provide a variety of fasteners. This can streamline procurement processes and ensure consistent quality across different types of nails and fasteners.

Conclusion

Yellow galvanized chipboard nails are an excellent choice for anyone involved in construction or woodworking due to their durability, corrosion resistance, and versatility. Manufacturers play a vital role in the quality of these fasteners, and choosing the right supplier is key to ensuring the success of any project. With several manufacturers in the market, due diligence in selecting a reliable partner can significantly impact the quality and longevity of the final product. So whether you're a craftsman working on a small project or a contractor managing large-scale constructions, investing in high-quality yellow galvanized chipboard nails is critical for achieving the desired results.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024