ก.พ. . 18, 2025 08:58

Back to list

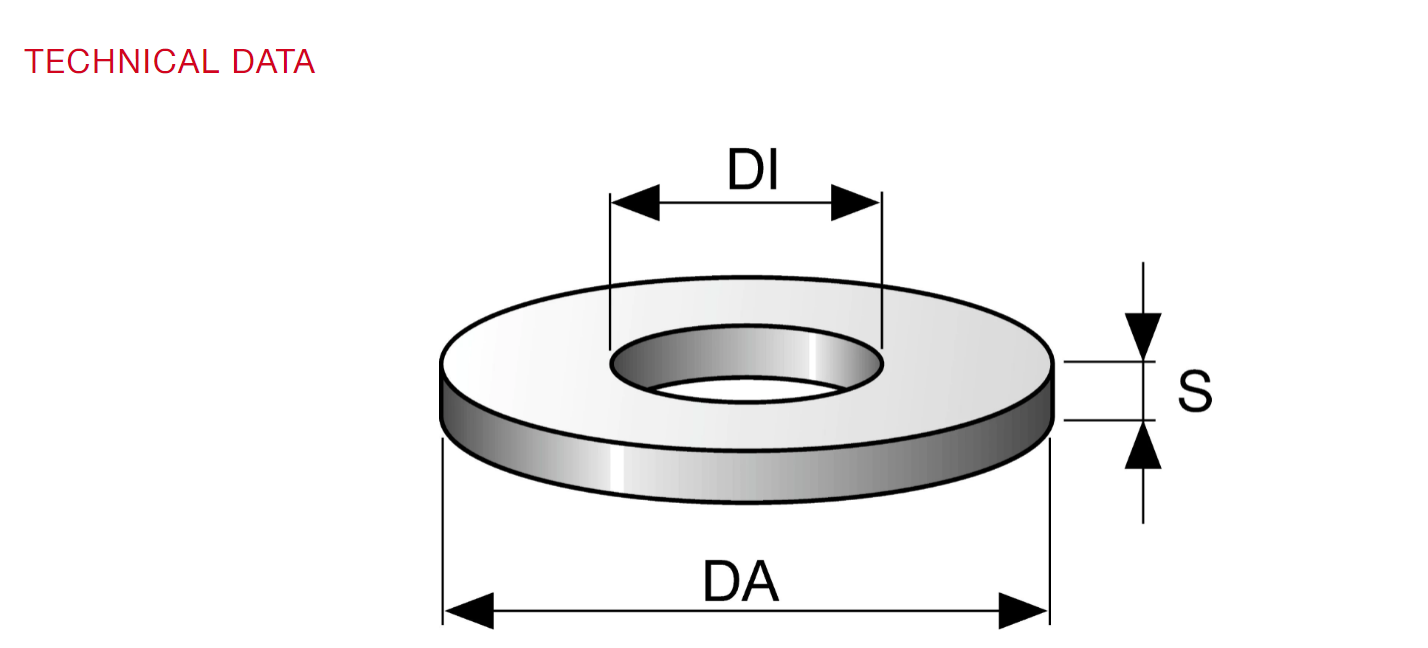

din125 plain washer flat washer

Stainless flat washers, though seemingly simple, play an indispensable role in the functionality and longevity of countless projects and products. Whether you're an engineer, a DIY enthusiast, or a purchasing manager for an industrial application, understanding stainless flat washers is paramount to achieving optimal performance in mechanical assemblies.

Build trust in your choice by considering the manufacturing standards that dictate the quality and performance of stainless flat washers. ISO and DIN standards, for instance, outline specifications for dimensions, material characteristics, and performance. Working with manufacturers that adhere to these standards ensures reliability and compatibility with other components in your assemblies. The practical experience of integrating stainless flat washers into projects reveals additional advantages. Besides reducing preloading losses in bolt assemblies, they help in alignment, especially in assemblies involving softer materials. Imagine an electrical component attached to a metallic body; using a stainless flat washer can prevent electrical conduction through the fastener, reducing the risk of galvanic corrosion or short circuits. In essence, selecting the right stainless flat washer is as much about understanding technical specifications as it is about applying practical experience to the unique demands of your project. The appropriate choice brings longevity and reliability, minimizing downtime and maintenance. For anyone involved in mechanical design or maintenance, a comprehensive understanding of these components is both a valuable expertise and a necessary authority. Purchasing managers should prioritize suppliers with proven histories of credibility and compliance with international standards. Partnering with reputable sources ensures not only the highest quality components but also the assurance of support and consistency in every order. Consequently, the investment in stainless flat washers transcends mere material cost, becoming an investment in the reliability and trustworthiness of your products or projects.

Build trust in your choice by considering the manufacturing standards that dictate the quality and performance of stainless flat washers. ISO and DIN standards, for instance, outline specifications for dimensions, material characteristics, and performance. Working with manufacturers that adhere to these standards ensures reliability and compatibility with other components in your assemblies. The practical experience of integrating stainless flat washers into projects reveals additional advantages. Besides reducing preloading losses in bolt assemblies, they help in alignment, especially in assemblies involving softer materials. Imagine an electrical component attached to a metallic body; using a stainless flat washer can prevent electrical conduction through the fastener, reducing the risk of galvanic corrosion or short circuits. In essence, selecting the right stainless flat washer is as much about understanding technical specifications as it is about applying practical experience to the unique demands of your project. The appropriate choice brings longevity and reliability, minimizing downtime and maintenance. For anyone involved in mechanical design or maintenance, a comprehensive understanding of these components is both a valuable expertise and a necessary authority. Purchasing managers should prioritize suppliers with proven histories of credibility and compliance with international standards. Partnering with reputable sources ensures not only the highest quality components but also the assurance of support and consistency in every order. Consequently, the investment in stainless flat washers transcends mere material cost, becoming an investment in the reliability and trustworthiness of your products or projects.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News