self tapping self drilling screw size chart exporters

Understanding Self-Tapping and Self-Drilling Screw Size Charts for Exporters

When it comes to construction, manufacturing, and various DIY projects, screws play a crucial role in ensuring the structural integrity and functionality of products. Among the numerous types of screws available, self-tapping and self-drilling screws are highly favored for their efficiency and user-friendly design. For exporters in the fastener industry, having a clear understanding of screw sizes and specifications is essential. A comprehensive self-tapping and self-drilling screw size chart is a vital resource that can streamline trade and enhance customer satisfaction.

What are Self-Tapping and Self-Drilling Screws?

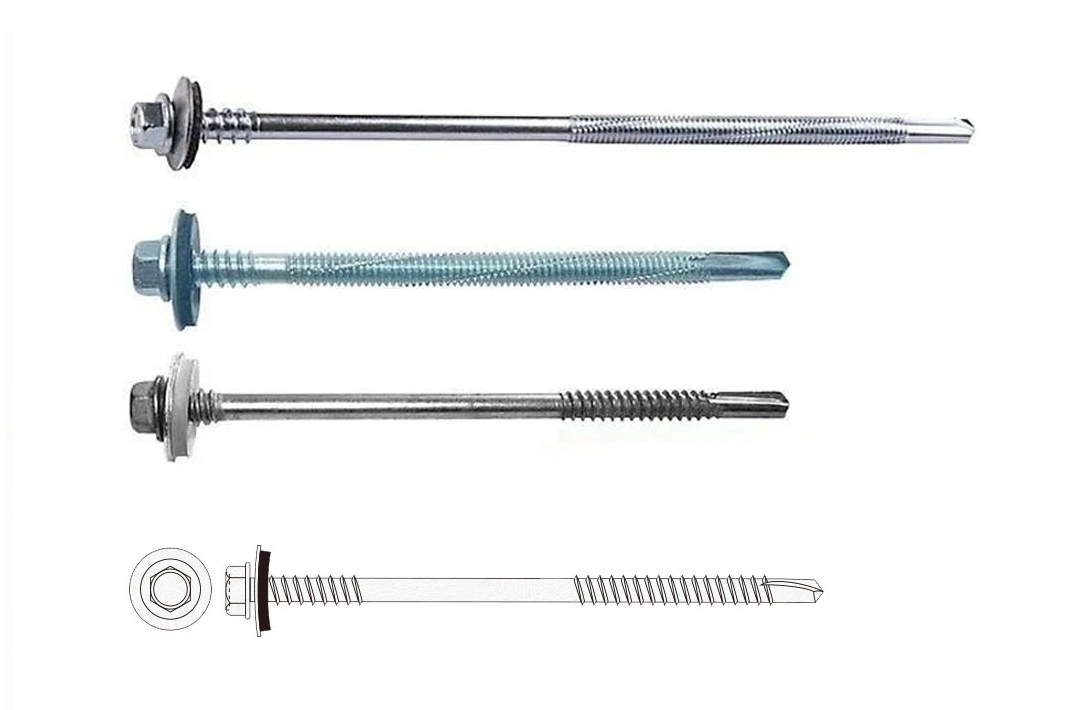

Self-tapping screws are designed to create their own hole as they are driven into materials. These screws can thread into various substrates, including wood, plastic, and metal, without the need for pre-drilling. They feature sharp threads and a pointed tip that helps them efficiently cut into the material.

On the other hand, self-drilling screws come with a drill tip that allows them to penetrate extremely hard materials. This feature eliminates the need for pilot holes, significantly speeding up assembly time and reducing the risk of damaging or splitting materials. Both types of screws are indispensable in construction, automotive manufacturing, and numerous industrial applications.

Importance of Size Charts

For exporters, understanding screw sizes is critical. A screw size chart provides vital information such as diameter, length, thread count, and head type. This information helps determine the appropriate screw for specific applications and ensures compatibility with materials used in construction or manufacturing.

1. Diameter and Length The diameter of a screw is typically measured in inches or millimeters. Understanding screw diameters helps in selecting the right screws that can securely hold materials together. The length of the screw is equally important, as it determines how deep the screw will penetrate, impacting the strength of the joint.

self tapping self drilling screw size chart exporters

2. Thread Count The number of threads per inch or the pitch of the threads is crucial for determining how fast and secure the screw will be when it is driven into the material. Different applications may require different thread designs to ensure optimal grip and holding power.

3. Head Types Self-tapping and self-drilling screws come in various head types, such as Phillips, slotted, hex, and Torx. The choice of head type can influence the ease of installation and the type of tools required for driving the screws.

Navigating Export Regulations

Exporting screws, like any other hardware products, comes with its own set of regulations and standards. Understanding the requirements of different countries can significantly affect business operations. Product specifications, including the size, material composition, and intended use, must align with importing country standards. Providing a size chart facilitating these criteria can enhance the chances of successful exports.

Meeting Customer Needs

In an increasingly competitive global market, the need to provide high-quality products that meet customer specifications is paramount. An easy-to-read size chart, complete with illustrations, can help clients make informed decisions, leading to increased customer satisfaction. It aids not only in selecting the right product but also in understanding the differences between self-tapping and self-drilling screws.

Conclusion

In conclusion, a detailed self-tapping and self-drilling screw size chart is an invaluable asset for exporters in the fastener industry. It serves as a practical tool for ensuring that customers receive the appropriate screws for their specific applications. The understanding of these screws' sizes, specifications, and their respective applications can facilitate smoother transactions and improve product satisfaction. As the demand for quality fastening solutions continues to rise, having robust resources like size charts will be a decisive factor in maintaining a competitive edge in the global market. By providing accurate, user-friendly information, exporters can enhance their credibility and foster lasting relationships with clients worldwide.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024